High heating value gas boiler

A gas boiler and high calorific value technology, applied in the boiler field, can solve the problem that the boiler is not suitable for high calorific value gas combustion, etc., and achieve the effect of rational use of energy and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

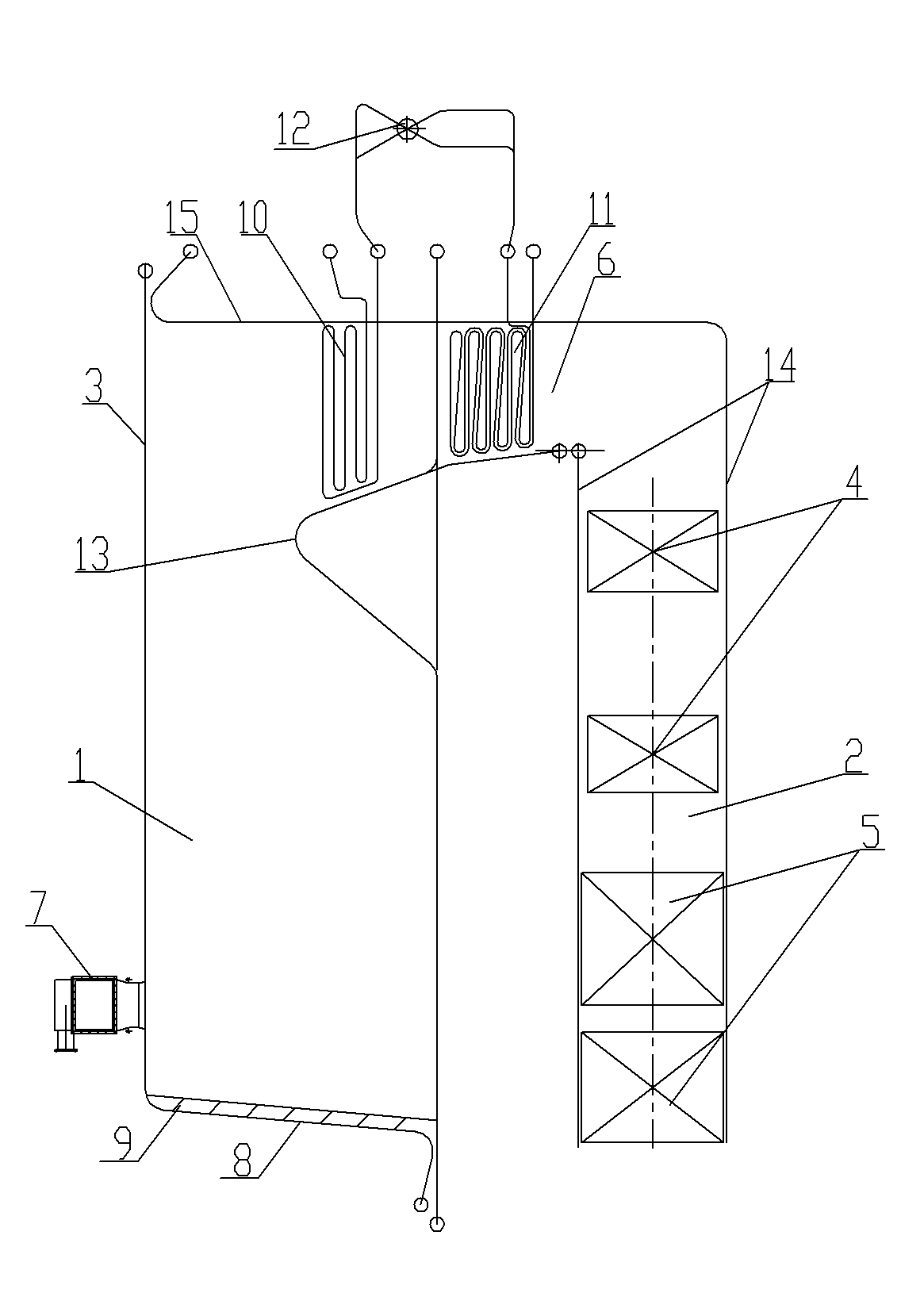

[0015] See figure 1 , which includes a furnace 1, a tail shaft 2, a water wall 3, a superheater, an economizer 4, an air preheater 5, and a horizontal flue 6. The upper part of the furnace 1 is connected to the upper part of the tail shaft 2 through a horizontal flue 6, and the furnace 1 is surrounded by water-cooled walls 3, the side wall of the tail shaft 2 is provided with a wall superheater 14, the side wall of the horizontal flue 6 is provided with a ceiling superheater 15, the water-cooled wall 3, the wall superheater 14, and the ceiling superheater 15 are all It is a membrane wall structure, at least two burners 7 are arranged side by side on the front wall of the furnace 1, the lower part of the front water cooling wall on the inner side of the front wall is inclined at 5° and then extends to the rear wall to form a furnace bottom water cooling wall 8, and the furnace bottom water cooling wall 8 A layer of refractory bricks 9 is arranged on the upper side, and the supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com