Small-size sintering cup device and method for performing sintering cup test by using same

A technology for sintering test and sintering cup, which is applied in the furnace control device, furnace type, furnace and other directions, can solve the problems of difficult to accurately control the amount of sintering material added, poor quality of sintered ore in the sintering cup, and large test workload, etc., to reduce labor The effect of small strength, material consumption and workload, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

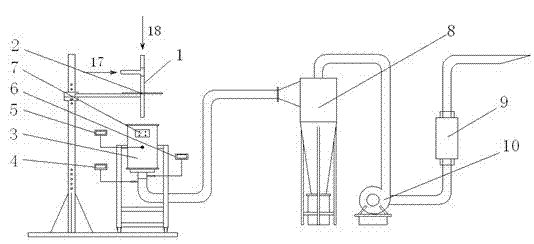

[0022] The present invention consists of an igniter 1, an igniter bracket 2, a furnace body 3, an exhaust gas temperature indicator 4, a furnace temperature indicator 5, a sintering negative pressure indicator 6, a thermal insulation power supply 7, a cyclone gravity dust collector 8, a muffler 9, and an exhaust fan 10 and sintering pot temperature control device.

[0023] Shown in the figure, the igniter 1 is fixed on the igniter bracket 2, the furnace body 3 is located under the igniter 2, and the igniter 1 is connected with the pipeline for conveying the fuel gas 17 and the combustion-supporting air 18, and the sintering placed in the furnace body 3 The ore is heated and sintered. The lower part of body of furnace 3 is connected with cyclone gravity dust collector 8 , and cyclone gravity dust collector 8 is connected with exhaust fan 10 , and exhaust fan 10 is also connected with muffler 9 .

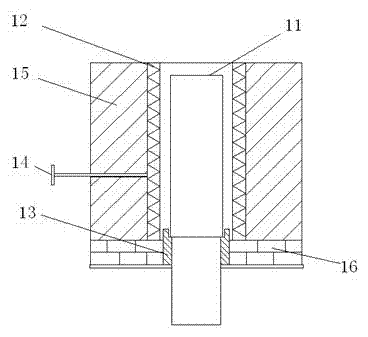

[0024] Shown in the figure, furnace body 3 is made up of pedestal 13, thermocoup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com