Multi-core carbon dioxide laser tube

A carbon dioxide and laser tube technology, applied to lasers, laser components, laser components, etc., can solve the problems of inconvenient transportation and use, insufficient stability, and high production costs, and achieve stable power, easy production, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

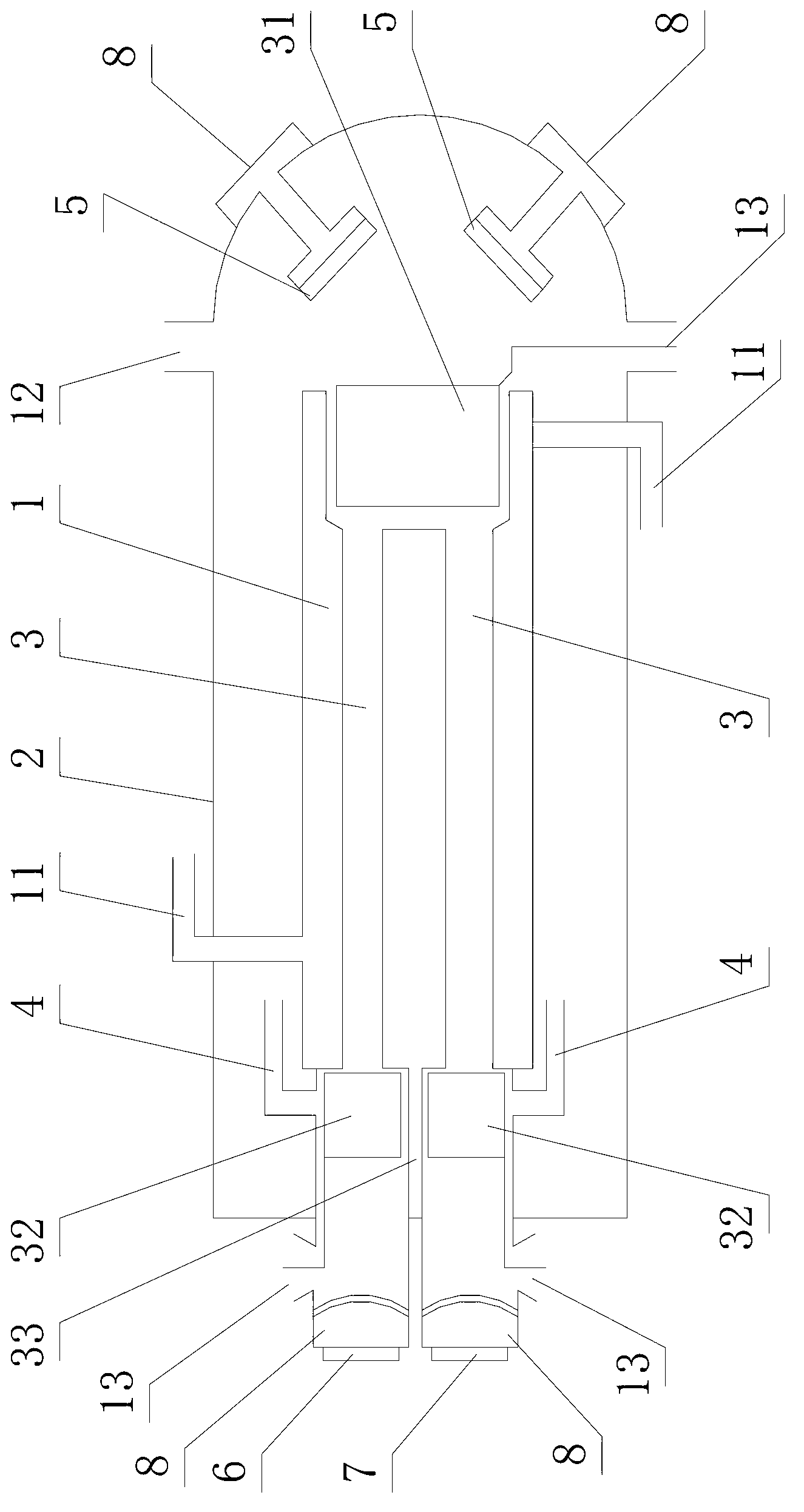

[0015] like figure 1 As mentioned above, a multi-core carbon dioxide laser tube includes a water-cooled tube 1, a gas storage tube 2 sleeved outside the water-cooled tube 1, two discharge tubes 3 sleeved inside the water-cooled tube 1, and two of the discharge tubes 3 It is arranged in parallel in the water cooling tube 1, one end of the two discharge tubes 3 is connected with an electrode interface I31, the other end of the two discharge tubes 3 is connected with an electrode interface II32, and an electrode interface II32 is connected between the two electrode interfaces II32. There is a water-vapor isolation plate 33, the two ends of the water-cooled pipe 1 are respectively connected with the electrode interface I31 and the water-vapor isolation plate 33, and the two electrode interfaces II32 are connected with the gas return pipe 4 communicated with the gas storage pipe 2, so Both sides of the water cooling pipe 1 are connected with water inlet and outlet pipes 11, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com