Permanent magnet linear synchronous motor system with low thrust fluctuation and parameter design method of system

A permanent magnet synchronous linear, low-thrust technology, applied in the direction of propulsion systems, electrical components, electromechanical devices, etc., can solve problems such as resonance, deterioration of servo operating characteristics, and inability to completely eliminate magnetic resistance, so as to reduce maintenance costs and optimize dynamics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principle of adding a compensating block to offset the magnetic resistance of the present invention can be used in various types of permanent magnet synchronous linear motors. The present invention is described in detail below.

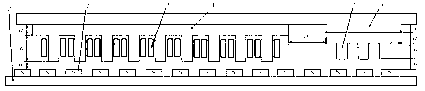

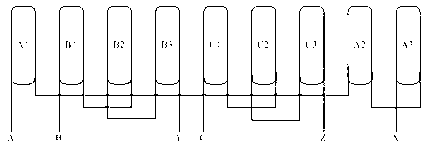

[0038] figure 1 Among them, the permanent magnet synchronous linear motor is composed of a primary iron core 4, a coil winding 3, a permanent magnet 2, and a secondary iron core 1, wherein the primary iron core 4 and the secondary iron core 1 are Steel_1008, a non-linear ferromagnetic material commonly used in motors; The coil winding 3 is enameled wire; the material of the permanent magnet 2 is NdFe30. The permanent magnet synchronous linear motor has a structure of 9 teeth and 10 poles (that is, the primary iron core 4 has 9 teeth, corresponding to 10 permanent magnets 2 on the secondary iron core 1), the coil winding 3 is a concentrated full-pitch winding, and the three-phase winding distribution is as follows figure 2 shown.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com