Fermentation device and microbial fermentation decomposition treatment method thereof

A technology of microbial fermentation and fermentation device, applied in the field of biotechnology, can solve the problems of blocking excretion pipes, affecting human health, and difficult to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

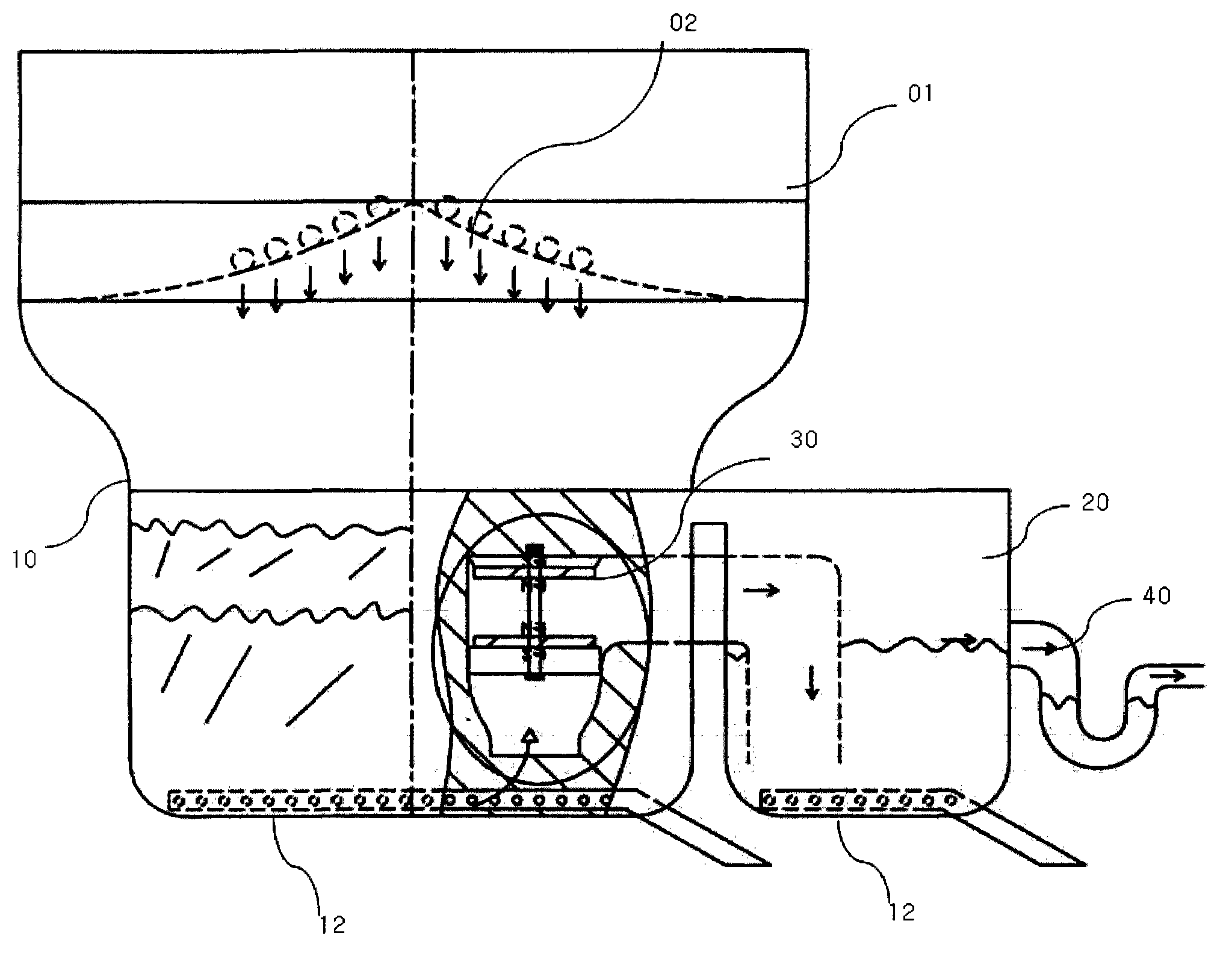

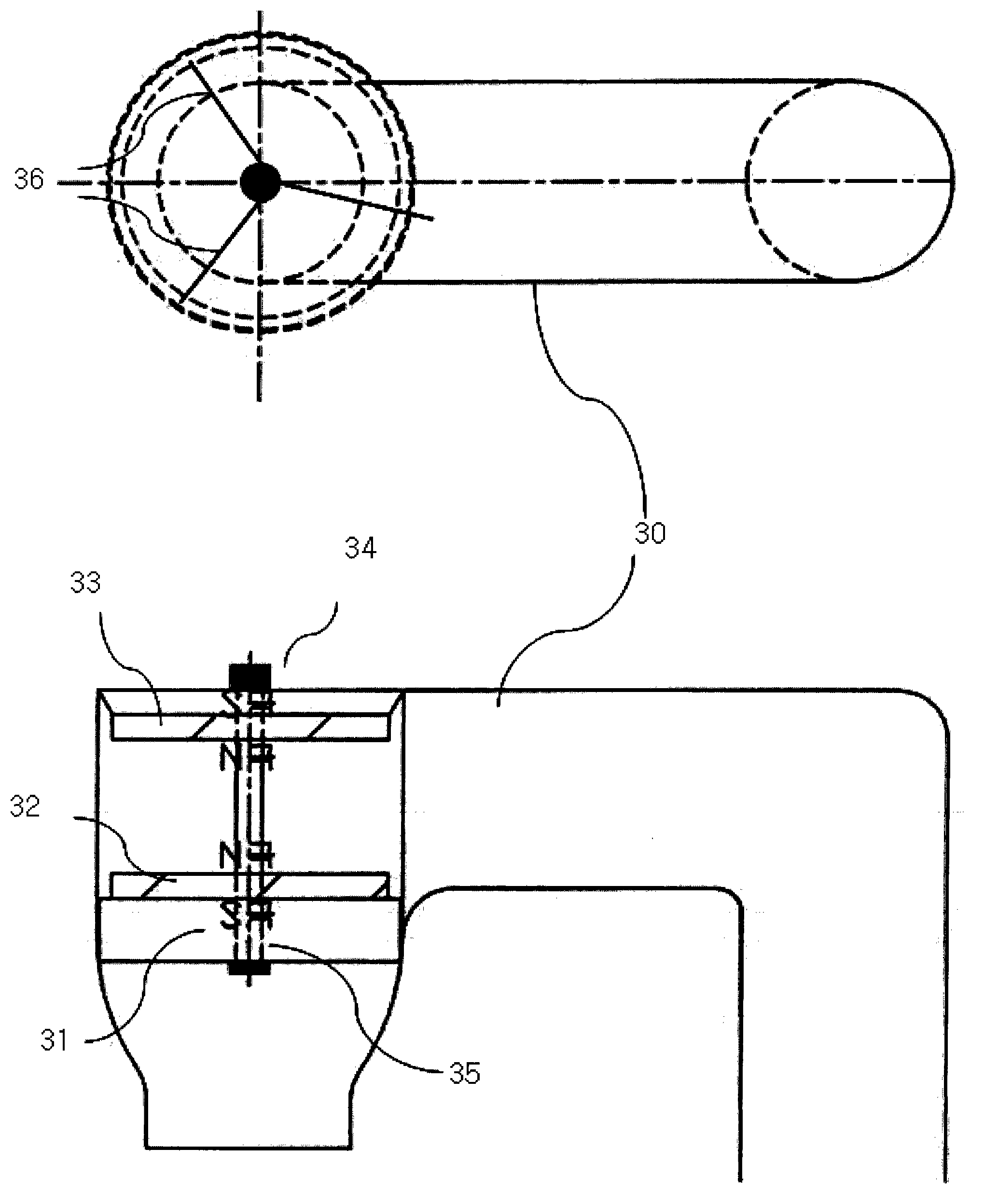

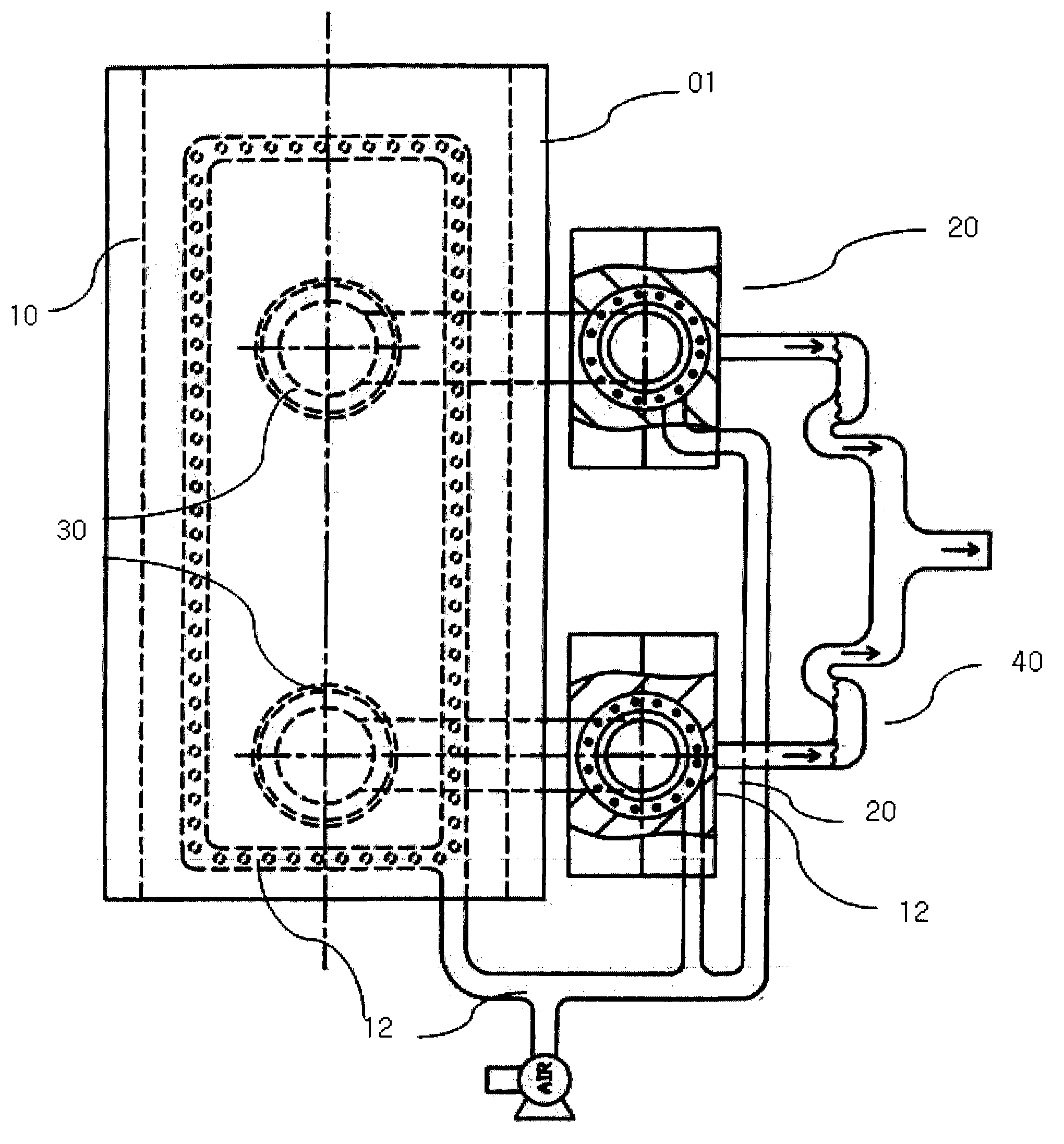

[0039] In order to achieve the above object, the structure of the present invention is to collect the primary sump 10 drained from the attached decomposition tank filter screen discharge hole 02 at the bottom of the food waste microbial fermentation decomposition tank 01; except the oil floating on the top, only discharge the following water, and utilize magnets to make water pass through under a certain water pressure, that is, the oily component separation valve 30 developed by the present invention; the secondary water collection tank 20 that is used to collect the treated water that has passed through the oily component separation valve again; The excretion is composed of an excretion pipe 40 and the like.

[0040] It should be noted that all expressions using "first" and "second" in the embodiments of the present invention are to distinguish two entities with the same name but different parameters or parameters that are not the same, see "first" and "second" It is only fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com