Testing device of machine tool spindle dynamics of numerically-controlled machine tool in cutting state

A technology for CNC machine tools and machine tool spindles. It is used in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc. It can solve the problems of error in analysis results, lack of experimental verification, and lack of convincing analysis results, and achieve stability. , to achieve the effect of analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

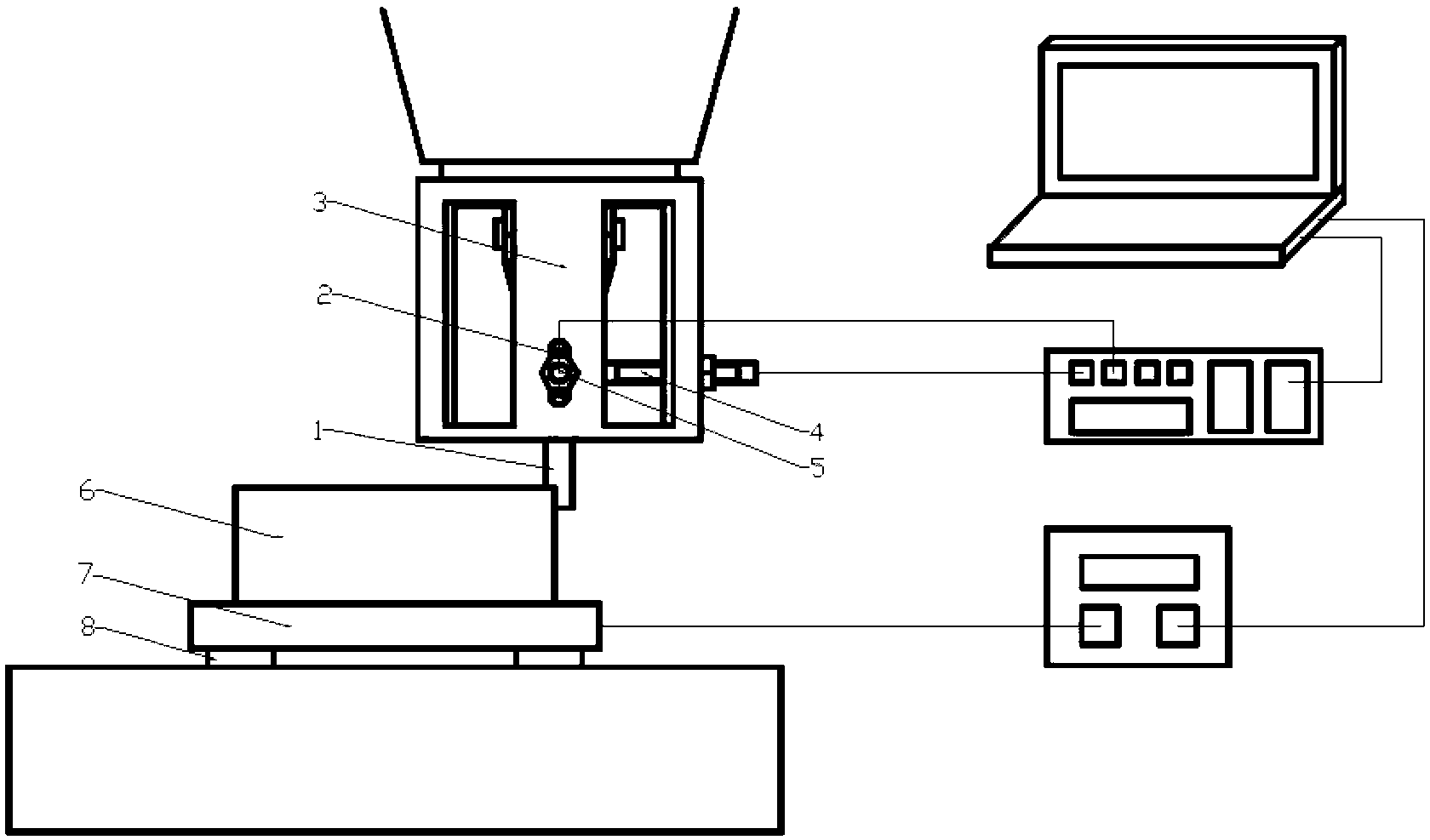

[0026] The following is a further detailed description of the dynamic testing device of the machine tool spindle under the cutting state of the CNC machine tool in combination with the working principle and the drawings of the mechanism.

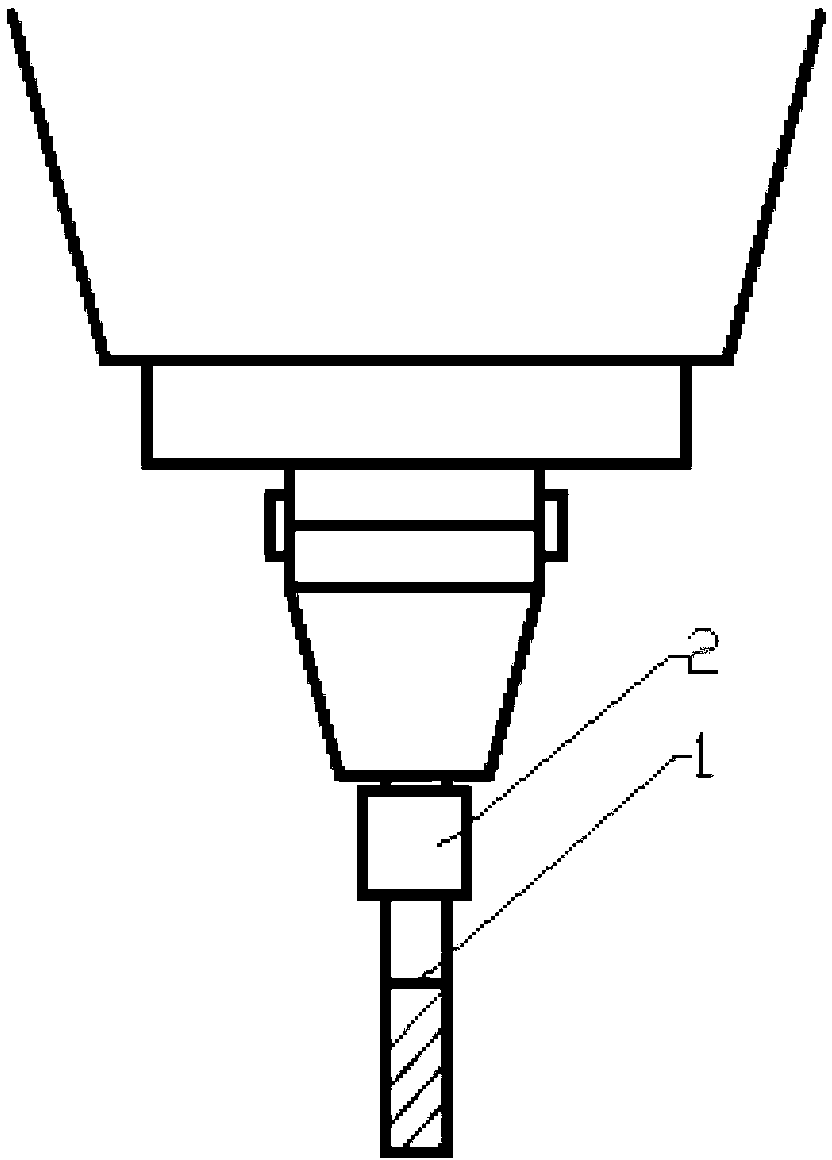

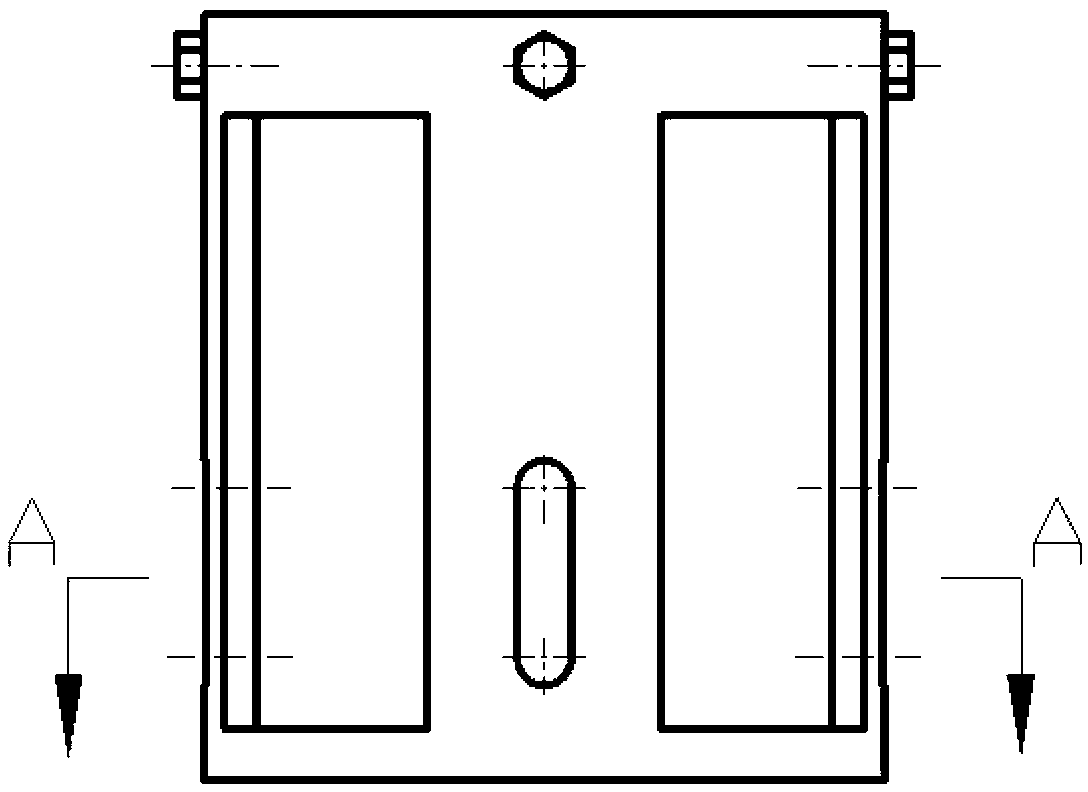

[0027] Such as figure 1 As shown, the middle of the outer surface of the milling cutter sleeve 2 is a smooth test strip with a width of 10 mm and a surface roughness of Ra1.6, and its outer diameter is equal to 5 times the diameter of the test end of the eddy current sensor. The milling cutter sleeve 2 is assembled on the handle of the milling cutter 1 through interference fit, and then the milling cutter 1 equipped with the milling cutter sleeve 2 is installed on the spindle handle of the CNC machine tool, and the milling cutter is measured by a dial gauge to ensure that the milling cutter The radial full run-out of the knife sleeve 2 outer surface smooth test belt is not greater than 0.01mm. The sensor support 3 is a cylindrical device, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com