Anti-slide valve power supply control circuit of high speed train

A power control circuit and high-speed train technology, applied in the direction of brakes, etc., can solve the problems of large impact on the braking system, economic losses in major safety accidents, etc., and achieve the effect of ensuring normal work, reliable operation, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

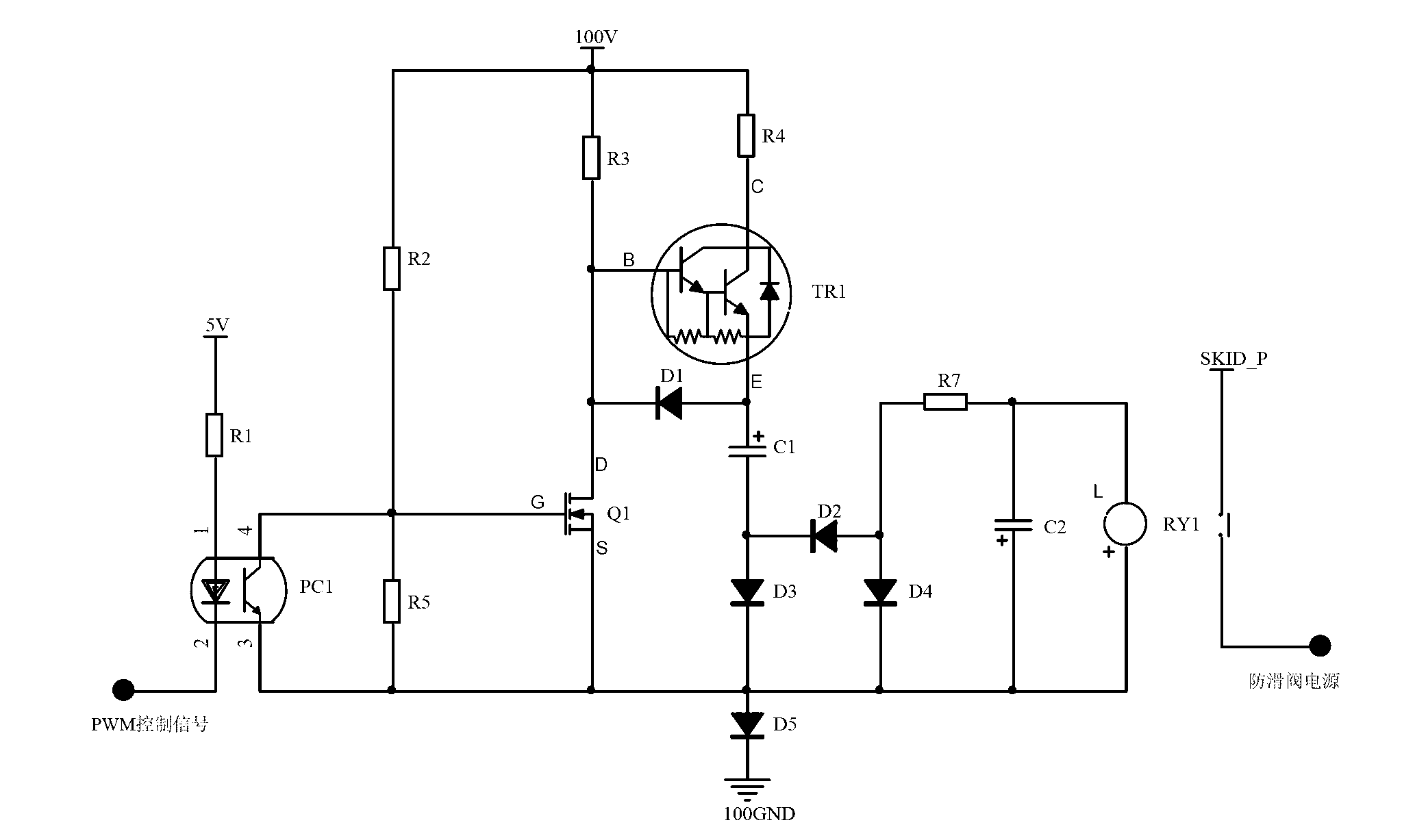

[0018] like figure 1 As shown, the high-speed train anti-skid valve power supply control circuit of the embodiment of the present invention consists of: a relay RY1 connected to the anti-skid valve power supply circuit, an isolated optocoupler PC1, a metal oxide half-field-effect transistor (MOSFET) Q1, a Darlington tube TR1, The first capacitor C1, the charging circuit of the first capacitor C1, the discharge circuit of the first capacitor C1, and the second capacitor connected in parallel with the relay coil L, the relay coil L is connected in ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com