Plastic polymer particle air purification sprayer and matched device thereof

An air purification and supporting equipment technology, applied in mining equipment, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of electrical equipment explosion, coal dust explosion, inconvenient control, etc., to achieve sensitive action, high output water pressure , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

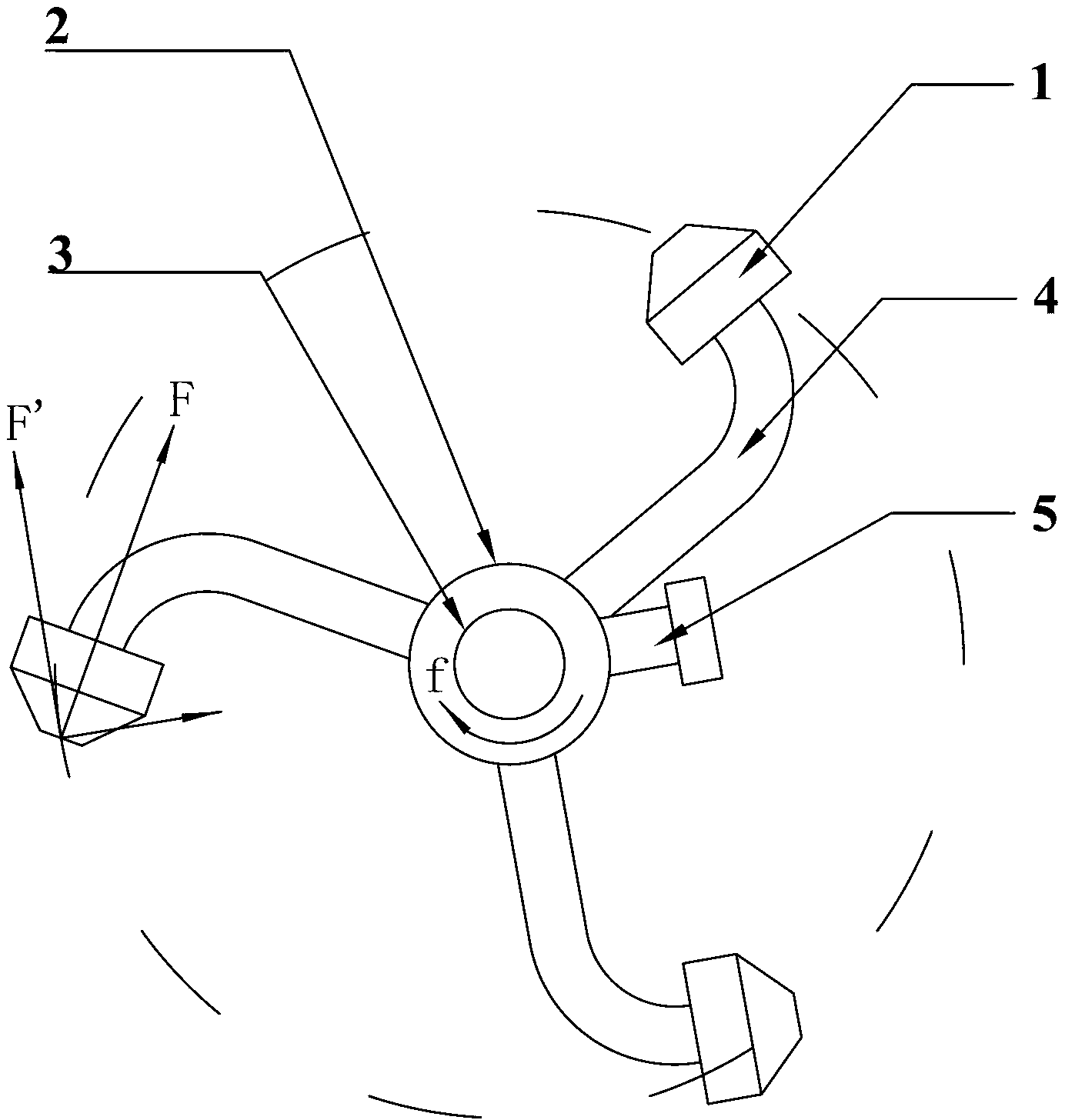

[0019] Implementation mode one: if figure 1 As shown, the plastic polymer particle air purification spray head and its supporting equipment include a spray head 1, a hollow shaft 2, a shaft sleeve 3 and a spray rod 4, the spray head 1 is a plastic polymer particle spray head, and the upper end of the hollow shaft 2 It extends into the shaft sleeve 3 and is provided with a bearing 7. A double-layer rubber sealing ring 5 is provided between the hollow shaft 2 and the shaft sleeve 7. The lower end of the hollow shaft 2 is provided with three interfaces 6; there are three spray rods 4, One end is connected to the access interface 6, and the other end is connected to the spray head 1. The axis of the spray head 1 and the axis of the hollow shaft 2 are straight lines in different planes. The component force F' is greater than the rotation resistance f of the hollow shaft 2, that is, F'>f; the top of the shaft sleeve 3 is fixed, and a water inlet is arranged on it. An inner expansio...

Embodiment approach 2

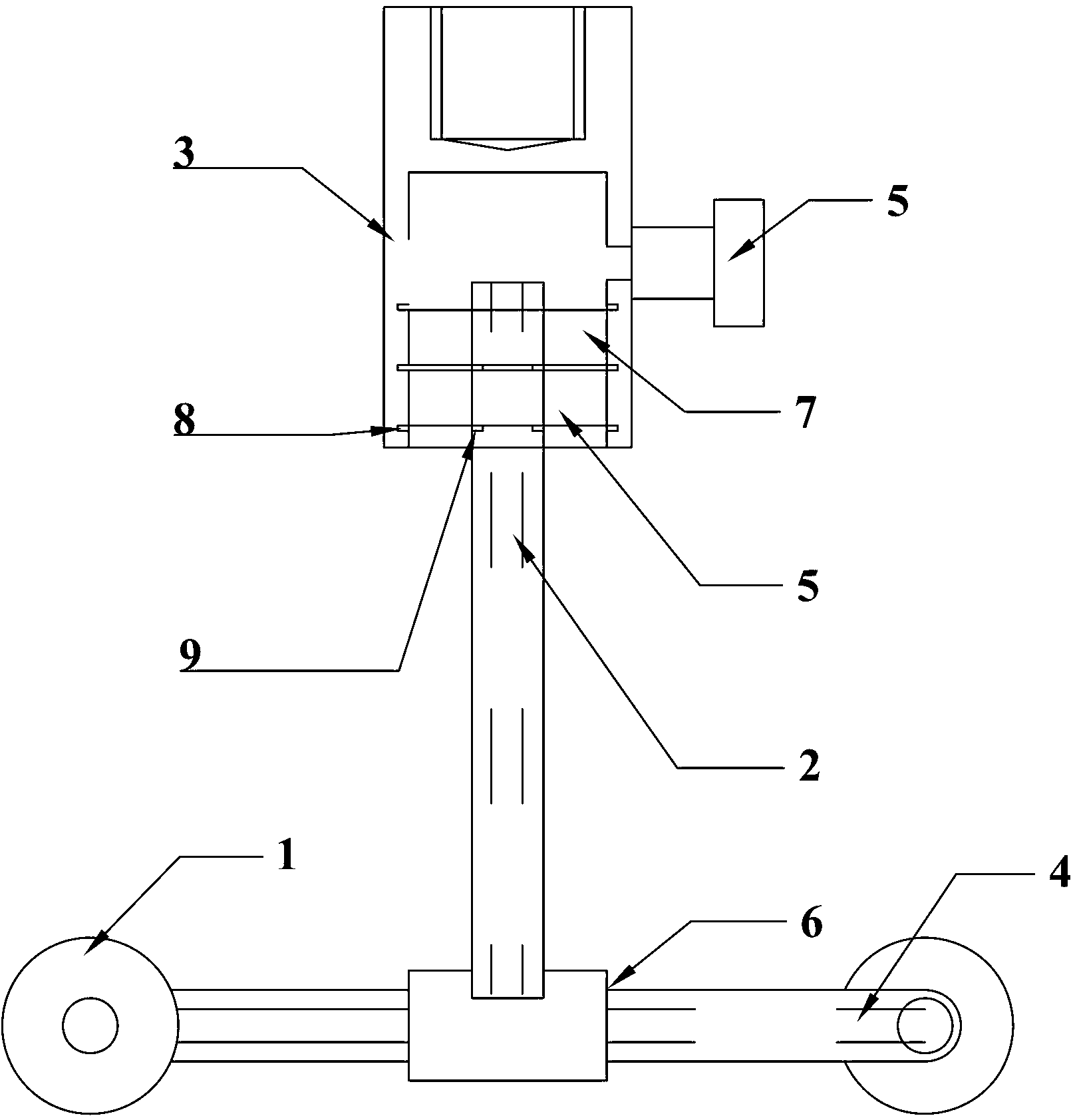

[0020] Implementation mode two: if figure 2 As shown: the plastic polymer particle air purification spray head and its supporting equipment include a spray head 1, a hollow shaft 2, a shaft sleeve 3 and a spray rod 4, the spray head 1 is a plastic polymer particle spray head, and the upper end of the hollow shaft 2 It extends into the shaft sleeve 3 and is provided with a bearing 7. A double-layer rubber sealing ring 5 is provided between the hollow shaft 2 and the shaft sleeve 3. There are three interfaces 6 at the lower end of the hollow shaft 2; there are three spray rods 4 in total. One end is connected to the access interface 6, and the other end is connected to the spray head 1. The axis of the spray head 1 and the axis of the hollow shaft 2 are straight lines in different planes. The component force F' is greater than the rotation resistance f of the hollow shaft 2, that is, F'>f; the top of the shaft sleeve 3 is fixed, and a water inlet is arranged on it. An inner ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com