Underground optical fiber flow sensor in oil field

A fiber optic flow and sensor technology, applied in the field of petroleum well logging instruments, can solve the problems that cannot meet the environmental requirements of petroleum downhole flow, and achieve the effect of high measurement sensitivity and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

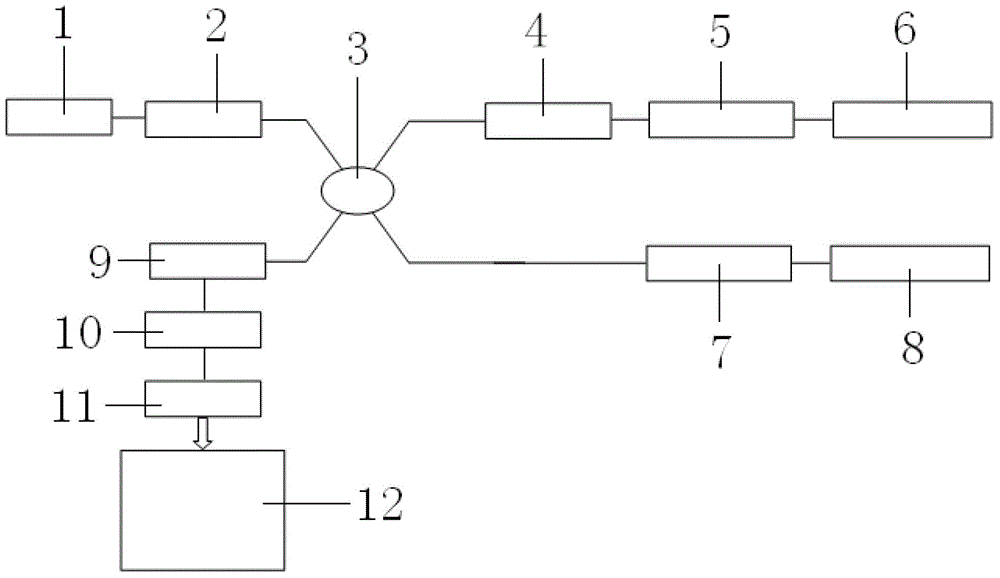

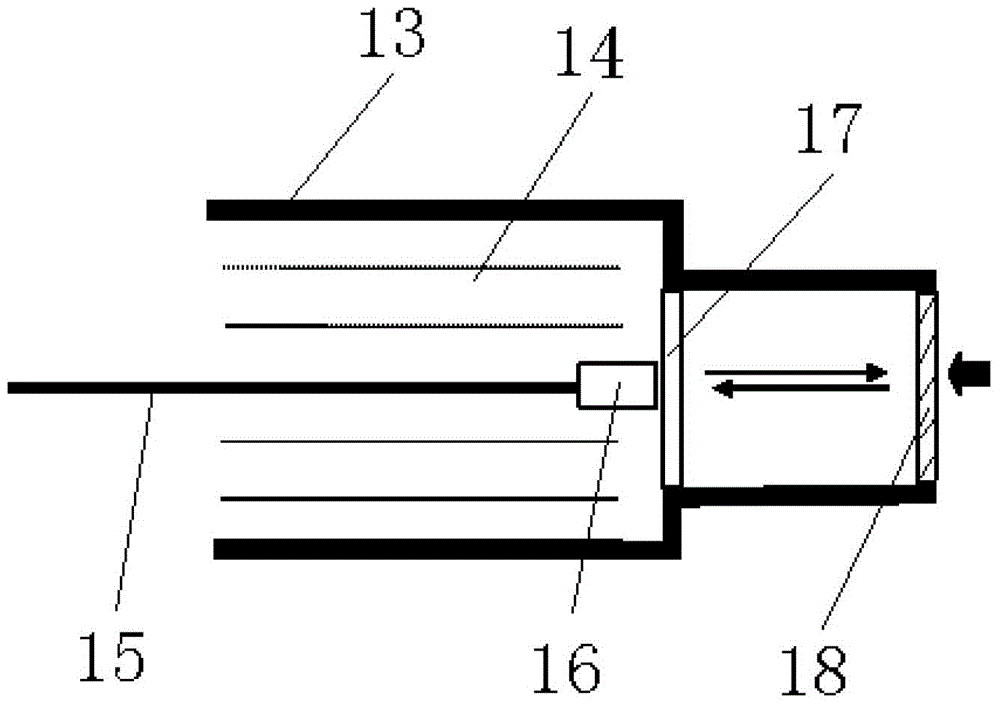

[0012] Such as figure 1 , figure 2 As shown, an oil field downhole optical fiber flow sensor includes a light source module 1; the light source module 1 is connected to a polarization controller 2, the polarization controller 2 is connected to a fiber coupler 3, and the fiber coupler 3 is connected to a phase modulator 4, Faraday rotator Ⅱ7 is connected with photodetector 9, phase modulator 4, Faraday rotator Ⅰ5, optical fiber pressure sensor Ⅰ6 are connected in sequence, Faraday rotator Ⅱ7 is connected with optical fiber pressure sensor Ⅱ8, photodetector 9, magnification The circuit 10, the A / D converter 11, and the embedded computer 12 are connected in sequence. The optical fiber pressure sensitive head I6 and the optical fiber pressure sensitive head II8 have the same structure. The optical fiber pressure sensitive head I6 and the optical fiber pressure sensitive head II8 include a stainless steel shell 13, a stainless steel shell A high-temperature resistant optical fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com