Compensation method for automatic temperature detection and automatic temperature detection system

A technology of automatic detection and compensation method, applied in the field of automatic temperature detection system, compensation of automatic temperature detection, and sensor measurement and control. The effect of the approximation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

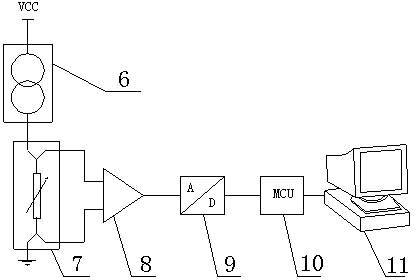

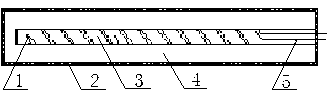

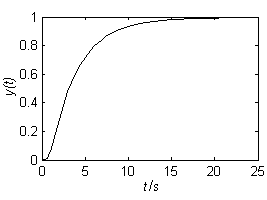

[0021] Such as figure 1 , 2 As shown, the constant current source (6) of the temperature automatic detection system is composed of a stable reference voltage source, an operational amplifier and a resistor. The stable reference voltage source is provided by LM236-2.5V, which provides a constant current for the system equipment, and the high-precision low-temperature drift operational amplifier OP07 is used to construct the operational amplifier. The output of the temperature sensor (7) is connected to the signal conditioning amplifier (8), and the signal conditioning amplifier (8) uses an AD620 instrumentation amplifier. The A / D converter (9) is composed of a single-chip microcomputer (10) with a 12-bit high-speed ADC inside the MSP430F169. Write a program to drive the single-chip microcomputer MSP430F169 (10) to collect the temperature sensor Pt 100 at a time inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com