Vibrating washout sensor

A vibration sensing and sensor technology, which is applied in the field of water conservancy engineering monitoring devices, can solve the problems of difficult real-time and accurate monitoring of pile foundation and embankment scouring status, potential safety hazards of structures, and many interference factors, and achieve simple, reliable and good measurement principles. The effect of economic benefit and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

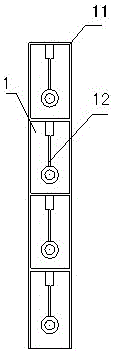

[0031] combine figure 1 , Vibration scour sensor, 1 includes a fixed frame 11 and a vibration sensing probe 12, and a vibration sensing probe 12 is arranged on the inside of the top of each layer of the fixed frame 11.

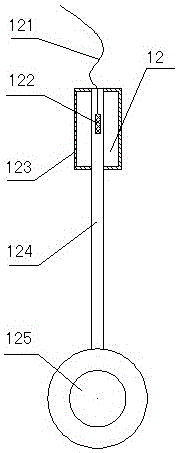

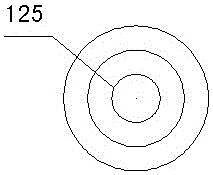

[0032] combine figure 2 As shown in FIG. 3 , the vibration sensing probe 12 includes a signal line 121 , a strain sensing element 122 , a protective case 123 , a conductive rod 124 , and a wave plate 125 . One end of the conductive rod 124 is connected to the edge of the wave plate 125, and the other end is pasted with the strain sensing element 122 and the signal line is drawn out. The protective shell 123 is a half metal cylinder with a bayonet opening at the center of the bottom surface. Two identical protective shells 123 are press-fitted to cover the strain sensing element 122 at the top of the conduction rod, and the remaining bayone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com