Falling weight impact testing machine

A drop-hammer impact test and heavy-hammer technology, applied in the field of testing machines, can solve the problems of wasting manpower and low work efficiency, and achieve the effects of improving work efficiency, recovering quickly, and preventing secondary impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

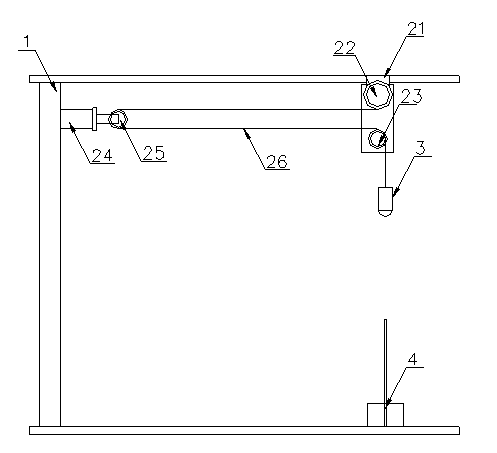

[0024] see figure 1 , as shown in the legend therein, a drop weight impact testing machine comprising:

[0025] a rack 1;

[0026] A lifting mechanism includes a driving motor 21, a cable reel 22, a positioning pulley 23, a high-speed cylinder 24, a movable pulley 25 and a cable 26,

[0027] One impact hammer 3;

[0028] and a loading mechanism 4;

[0029] The positioning pulley 23 is located above the loading mechanism 4;

[0030] The high-speed cylinder 24 is fixed on the frame 1;

[0031] Movable pulley 25 is connected on the piston rod of high-speed cylinder 24;

[0032] The free end of the cable 26 walks around the movable pulley 25 and the positioning pulley 23 successively, and then connects on the impact weight 3 .

[0033] The speed at which the piston rod of the high-speed cylinder 24 releases the cable is greater than the free-fall speed of the impact weight 3 .

[0034] The working principle of the present invention is introduced below.

[0035] Driven by ...

Embodiment 2

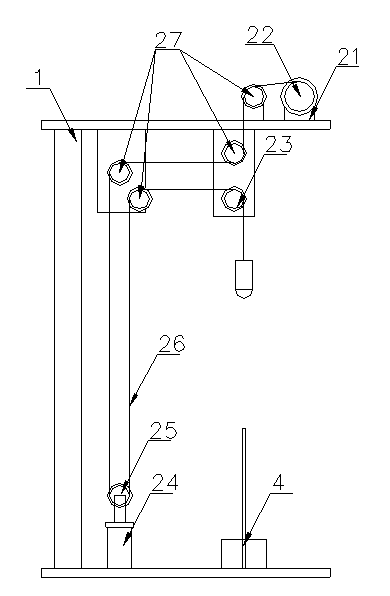

[0037] see figure 2 , as shown in the legend therein, the rest is the same as the embodiment, the difference is that the lifting mechanism also includes four auxiliary pulleys 27,. Adopting this structure makes the structure of the hammer impact testing machine more compact.

Embodiment 3

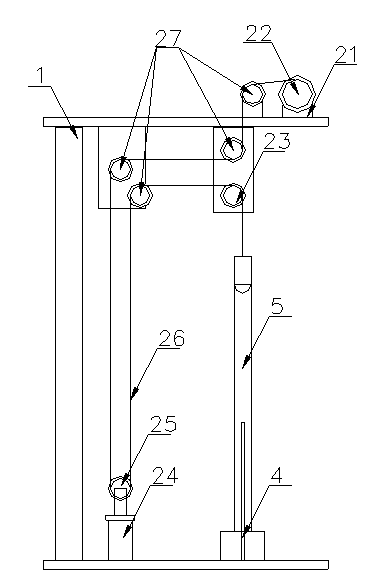

[0039] The rest are the same as in the embodiment 2, the difference is that the drop weight impact testing machine also includes a photoelectric sensor, the photoelectric sensor is arranged at the loading mechanism 4, and when the impact test is completed, the photoelectric sensor senses the corresponding signal , thereby controlling the rapid retraction of the piston rod of the high-speed cylinder 24, so that the impact weight 3 that completes the impact test is rapidly raised, avoiding the secondary impact of the workpiece to be tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com