Accurate off-line shaft fixing device and method of wedge-shaped lens disassembly and assembly unit

A lens and wedge-shaped technology, which is applied in the field of precise off-line alignment device for wedge-shaped lens dismounting unit, can solve the problems of inability to realize high-batch and high-precision alignment of large-diameter wedge-shaped lens dismounting unit, and achieve efficient batch assembly and calibration , Improve efficiency and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

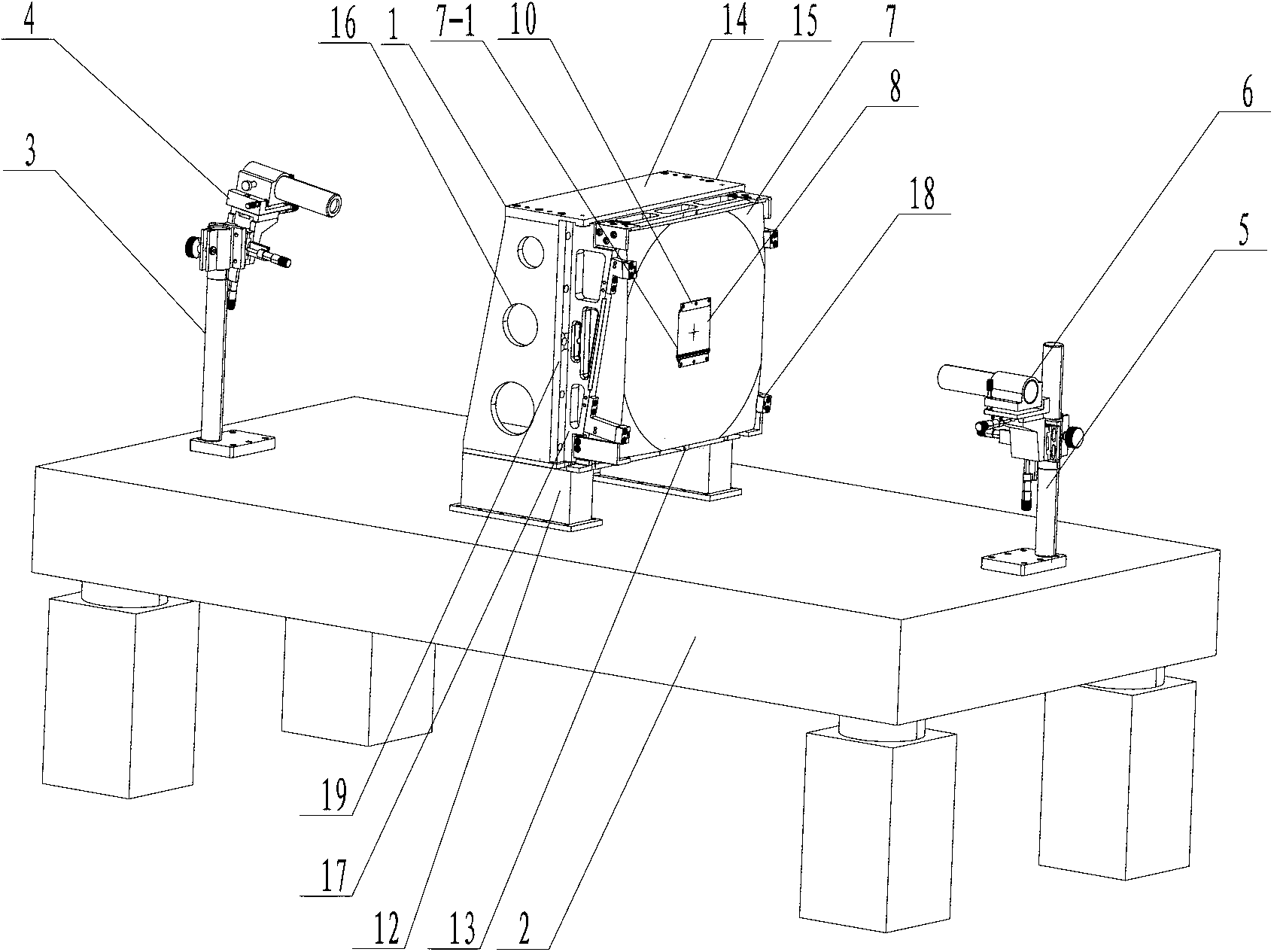

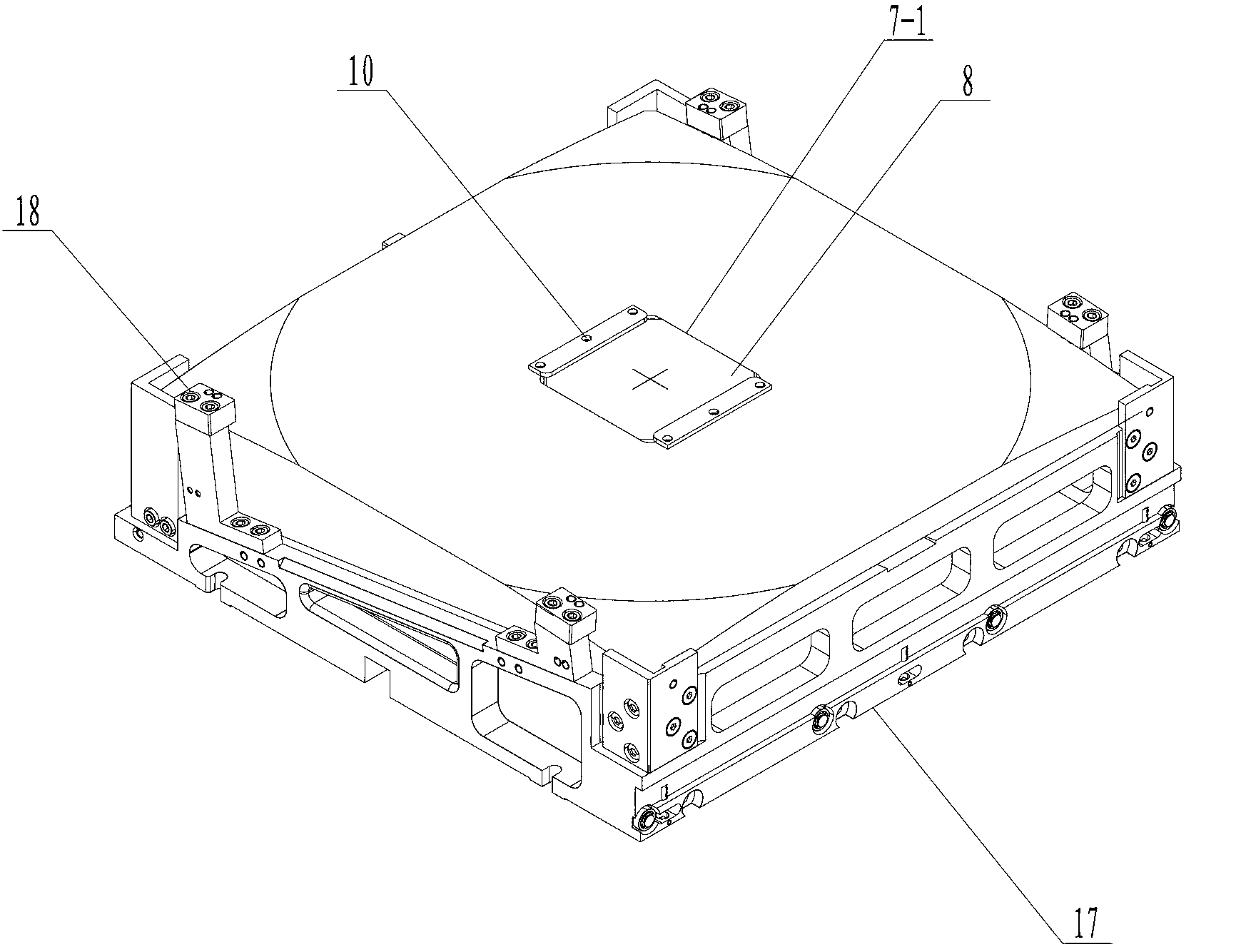

[0033] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, a precise off-line axis-fixing device for a wedge lens dismounting unit in this embodiment includes a wedge lens optical-mechanical assembly frame 1, an optical table 2, a first inner focusing autocollimator base 3, a first inner The focusing autocollimator 4, the second inner focusing autocollimator base 5 and the second inner focusing autocollimator 6, the wedge lens optical mechanical assembly frame 1 is arranged in the middle of the optical platform 2, the first inner focusing autocollimator The focus autocollimator base 3 and the second inner focus autocollimator base 5 are respectively arranged on both sides of the wedge lens optical-mechanical assembly frame 1, the first inner focus autocollimator 4 and the second inner focus autocollimator 4 and the second inner focus autocollimator base 5 respectively. The collimator 6 is respectively arranged on the first inner focusing auto...

specific Embodiment approach 2

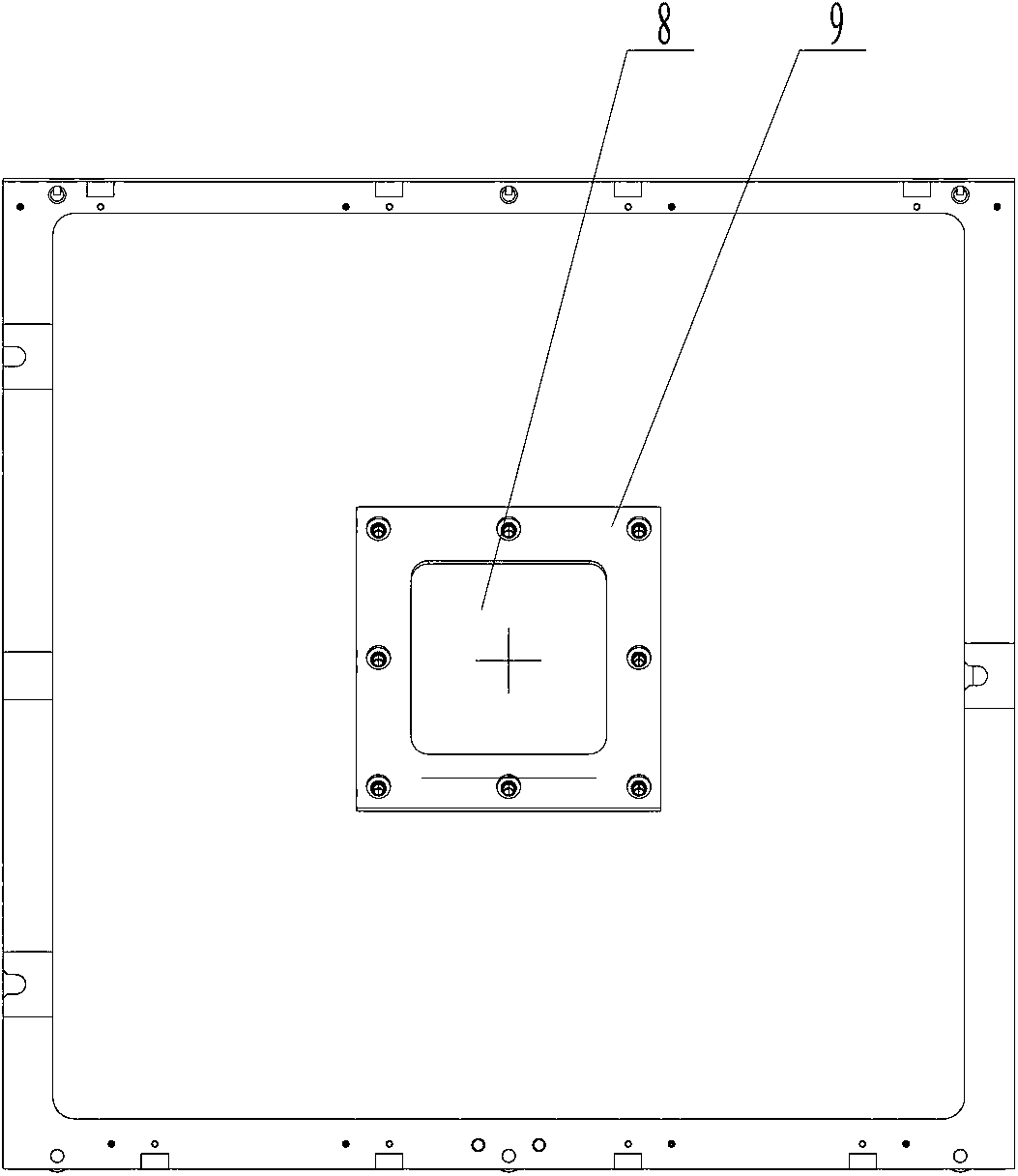

[0035] Specific implementation mode two: combination figure 1 The present embodiment is described, and the center of the front and rear surfaces of the standard wedge 8 of the present embodiment is engraved with fine cross hairs. With such setting, as the reference object of the fixed axis, the position of the fixed axis is more accurate. Other compositions and connections are the same as in the first embodiment.

[0036] The front and rear surfaces of the standard wedge in this embodiment depict fine cross wires, the wedge angle of the standard wedge is the same as the theoretical wedge angle of the wedge lens, and the positions of the two cross wires on the front and rear surfaces are determined according to the theoretical optical axis of the wedge lens, and are determined by Realized by mechanical scribing or coating technology.

specific Embodiment approach 3

[0037] Specific implementation mode three: combination figure 1 Describe this embodiment, the wedge lens substitute part of this embodiment is used for simulating the actual wedge lens online dismounting unit, the center of the crosshairs on the front surface of the standard wedge 8 represents the optical axis of the front surface of the wedge lens, and the rear surface of the standard wedge 8 The center of the crosshair represents the optical axis of the rear surface of the wedge lens, and its positioning method and positioning accuracy are exactly the same as the positioning method and positioning accuracy of the wedge lens online disassembly unit in the large-aperture optical focusing and frequency conversion system. With such setting, the positioning accuracy is high. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com