Composite medical dressing using calcium alginate fibers

A calcium alginate fiber, medical technology, applied in dressings, viscous dressings, medical science and other directions, can solve problems such as the inability to balance cost and dressing performance, influence of dressing permeability, complicated processing technology, etc., to improve moisture absorption and breathability, Good hygroscopicity and comfortable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

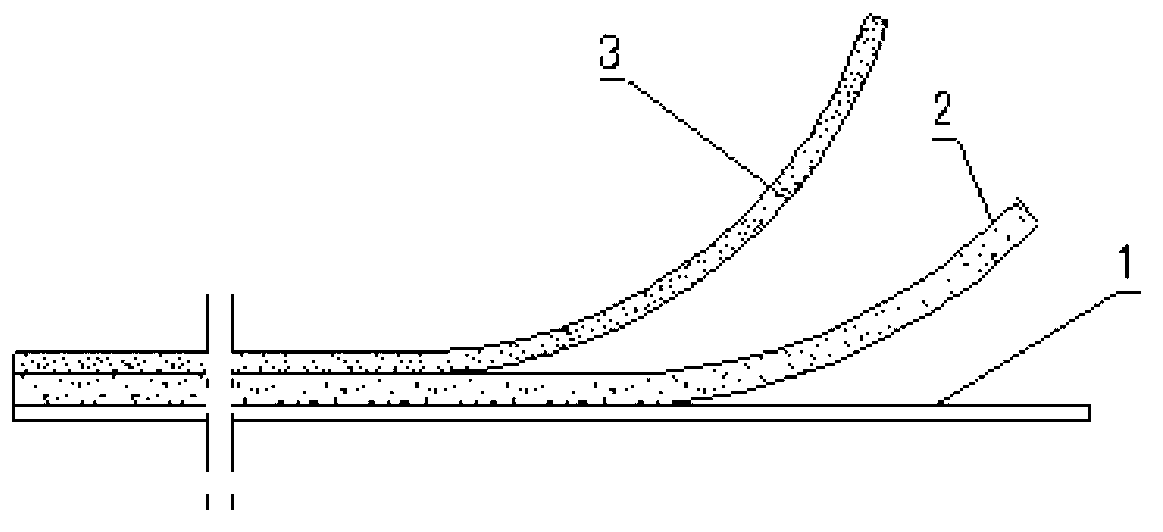

[0026] Such as figure 1 As shown, the composite medical dressing using calcium alginate fibers includes a surface layer 1, an intermediate layer 2 and a wound contact layer 3, and the surface layer 1 is named after the position of the layer in use. The medical dressing can use commonly used packaging.

[0027] The surface layer of embodiment 1 is a polyester fiber nonwoven fabric, and the grammage is 40g / m 2 , the middle layer 2 and the wound contact layer 3 are needle-punched nonwoven fabrics mixed with calcium alginate fibers and polyvinyl alcohol fibers, wherein the content of calcium alginate fibers in the middle layer is 40%, and the content of polyvinyl alcohol fibers is 60%. The weight of the middle layer is 30g / m 2 , the content of calcium alginate fiber in the wound contact layer is 99%, the content of polyvinyl alcohol fiber is 1%, and the weight of the wound contact layer is 30g / m 2 .

[0028] The compound medical dressing gram weight of embodiment 1 is 100g / m ...

Embodiment 2

[0030] Such as figure 1 As shown, the composite medical dressing using calcium alginate fibers in Example 2 includes a surface layer 1 , an intermediate layer 2 and a wound contact layer 3 . The medical dressing can use commonly used packaging.

[0031] The surface layer of embodiment 2 is a polyester fiber nonwoven fabric, and the grammage is 45g / m 2 , the middle layer 2 and the wound contact layer 3 are needle-punched nonwoven fabrics mixed with calcium alginate fibers and polyvinyl alcohol fibers, wherein the content of calcium alginate fibers in the middle layer is 55%, and the content of polyvinyl alcohol fibers is 45%. The weight of the middle layer is 50g / m 2 , the content of calcium alginate fiber in the wound contact layer is 90%, the content of polyvinyl alcohol fiber is 10%, and the weight of the wound contact layer is 40g / m 2 .

[0032] The compound medical dressing gram weight of embodiment 2 is 135g / m 2 ; The selected calcium alginate fiber has a fineness of...

Embodiment 3

[0034] Such as figure 1 As shown, the composite medical dressing using calcium alginate fibers in Example 3 includes a surface layer 1 , an intermediate layer 2 and a wound contact layer 3 . The medical dressing can use commonly used packaging.

[0035] The surface layer of embodiment 3 is a polyester fiber nonwoven fabric, and the grammage is 50g / m 2 , the middle layer 2 and the wound contact layer 3 are needle-punched nonwoven fabrics mixed with calcium alginate fibers and polyvinyl alcohol fibers, wherein the content of calcium alginate fibers in the middle layer is 70%, and the content of polyvinyl alcohol fibers is 30%. The weight of the middle layer is 80g / m 2 , the content of calcium alginate fiber in the wound contact layer is 80%, the content of polyvinyl alcohol fiber is 20%, and the weight of the wound contact layer is 50g / m 2 .

[0036] The compound medical dressing gram weight of embodiment 3 is 180g / m 2 ; The selected calcium alginate fiber has a fineness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com