Horizontal disc type diatomite filter

A diatomite filter, disc type technology, applied in filtration separation, moving filter element filters, separation methods, etc., can solve the problems of low automation, high filtration cost, low filtration efficiency, etc., and achieves convenient operation, High filtration efficiency and less filtrate loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

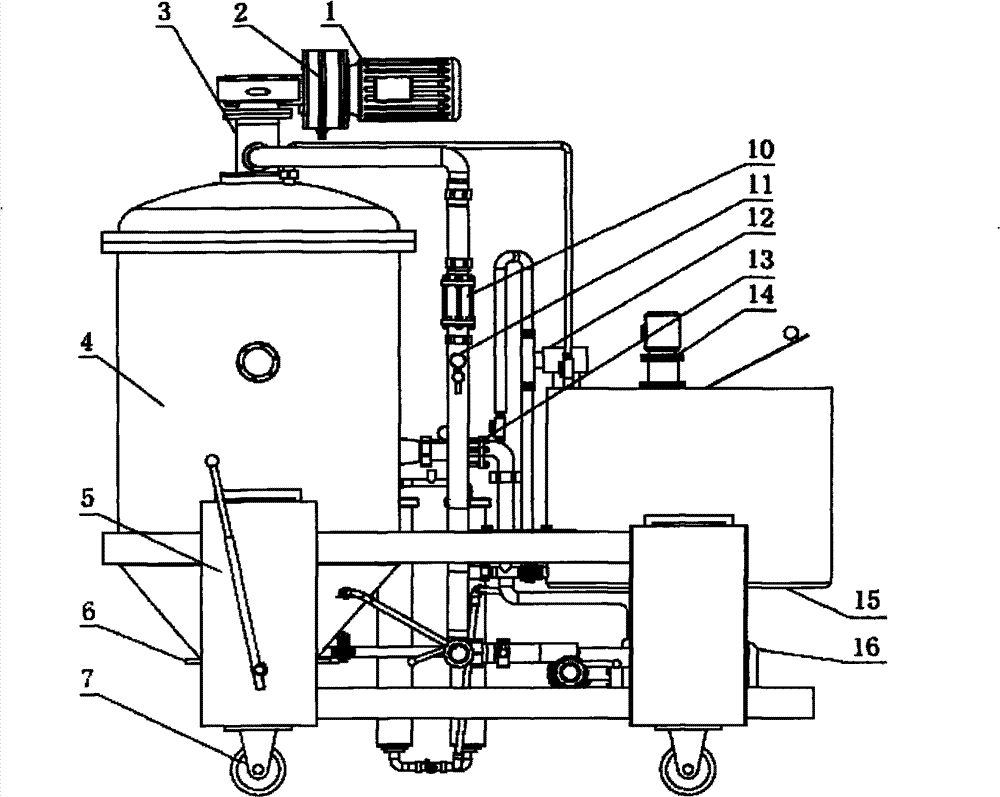

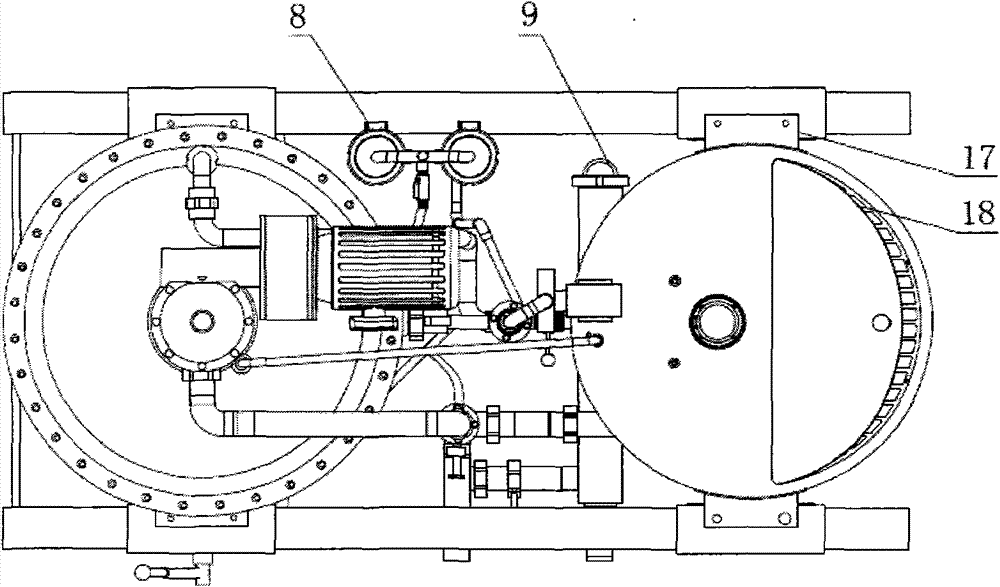

[0009] Such as figure 1 , figure 2 As shown, a horizontal disc type diatomite filter includes a reducer 1, a hydraulic coupling 2, a connecting frame 3, a vertical filter tank 4, a movable support 5, a slag discharge door 6, and a support wheel 7 , residual liquid filter 8, punching mesh filter 9, glass wheel flowmeter 10, sampling valve 11, diatomaceous earth adding pump 12, glass sight glass 13, second reducer 14, stirring tank 15, stirring tank filter 18. ZS single-stage centrifugal pump 16, base 17, etc. The vertical filter tank 4 and the mixing tank 15 are installed on the base 17 through the movable support 5, the base 17 is provided with a support wheel 7, the bottom of the vertical filter tank 4 is provided with a slag discharge door 6, and the vertical filter tank 4 is There is a central tube at the shaft position, the conical filter disc is set on the central tube, the conical filter discs are separated by a gasket, and the contact surface between the gasket ring ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap