Upsetter mould cooling and lubricating device

A technology of lubricating device and die cooling, applied in forging/pressing/hammer devices, heating/cooling equipment, manufacturing tools, etc., to achieve the effect of lubricating cleaning, improving automation and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

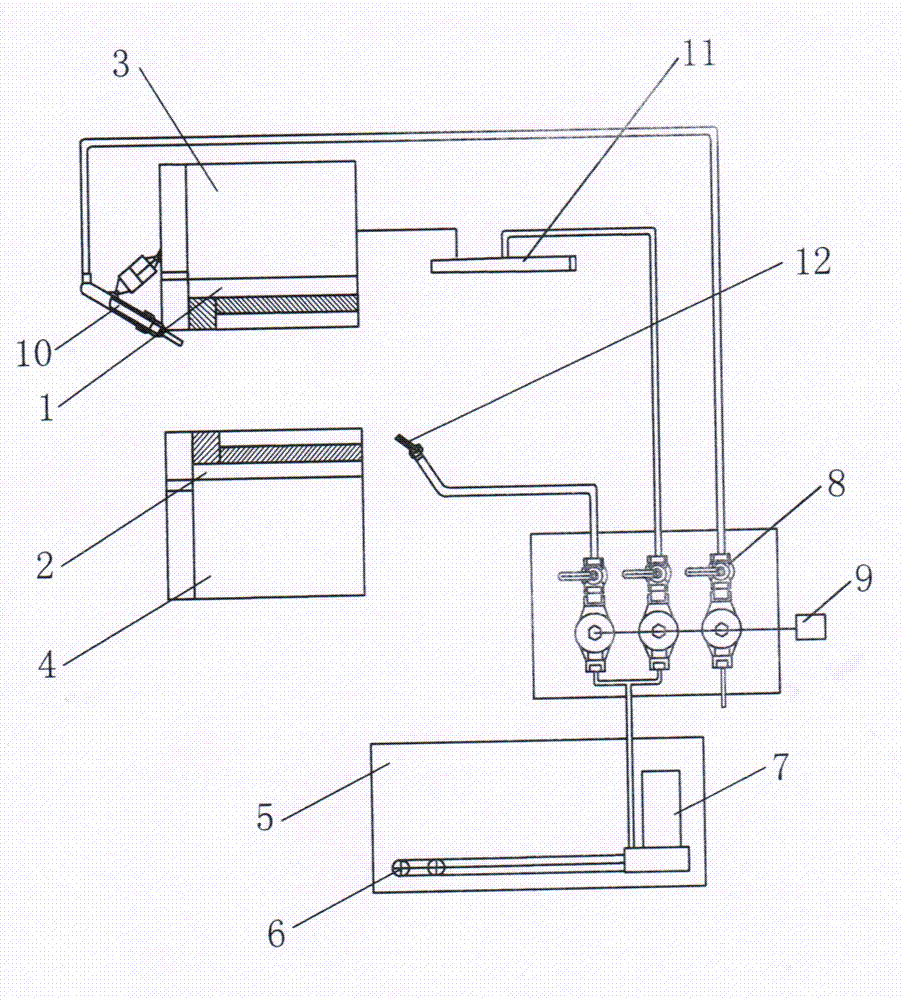

[0009] As shown in the figure, the PLC controller 9 is connected to the three diaphragm solenoid valves 8 respectively through wires, one of the diaphragm solenoid valves is connected to the compressed air source; the input ports of the other two diaphragm solenoid valves are connected to the water pump 7 through conduits. connection, the water pump is installed in the water-based graphite milk tank 5, and a compressed air agitator 6 is installed at the bottom of the water-based graphite milk tank; The device 11 is connected; among them, the universal graphite milk nozzle is placed on the side of the mold cavity, and the adjustable sprinkler is placed on the side of the tire plate 3 on the upsetting machine; the upper end of the diaphragm solenoid valve connected with the compressed air source passes through the conduit Connected with the compressed air nozzle 10, the compressed air nozzle is installed on the side of the upper tire plate of the upsetting machine; the upper abra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com