Method for manufacturing colored metal model by three-dimensional (3d) digital model

A digital model and colored metal technology, applied in special decorative structures, decorative arts, etc., can solve the problems of being unable to draw high-precision patterns and realistic colors, only suitable for mass production, and difficult to adapt to metal models, etc., to achieve bright colors The effect of color and pattern, superior texture and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Starting from the Rubik's Cube 3D digital model to make a Rubik's Cube stainless steel model:

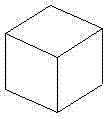

[0047] ⑴Open Autodesk 3ds Max, select the "Create" option, then select "Cuboid" in "Geometry", select "Cube" in the "Creation Method", and then draw a 3D digital model of a cube on the drawing page, such as figure 1 shown;

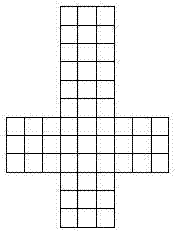

[0048] ⑵Select the "Material Editor" option in "Rendering", and then select "Compact Material Editor"; in the "Blinn Basic Parameters" column in the "Material Editor", select the "M" button behind "Diffuse Reflection"; click The "Address Box" behind the "Bitmap" selects the texture file that has been prepared, and assigns the texture to the "Material Ball", and the 3D digital model is pasted with a color texture (such as figure 2 , does not indicate the color); click the "green button" in the upper left corner of the software, select the "Export" option in the "Export" to export the model as an OBJ format file;

[0049] (3) Open the 3D dig...

Embodiment 2

[0060] Example 2: Starting from the 3D digital model of the five-pointed star to make a stainless steel model of the five-pointed star:

[0061] ⑴Open Autodesk 3ds Max, select the "Create" option, then select "Star" in "Graphics", set "Point" to 5 in "Parameters", and then draw a five-pointed star graphic on the drawing page; select the drawn For the five-pointed star graphic, select the "Modify" menu, find "Chamfer" in the "Modifier List" and set the "Chamfer Value" to "Height" 10, "Contour" -35 (negative number), and the 3D digital model of the five-pointed star Created, such as Figure 7 ;

[0062] ⑵Select the "Material Editor" option in the "Rendering" menu, and then select "Compact Material Editor"; In the "Blinn Basic Parameters" column in the "Material Editor", select the "M" button behind "Diffuse Reflection"; Click the "Address Box" behind the "Bitmap" to select the prepared texture file, assign the texture to the "shader ball", and the 3D digital model will be pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com