Motor train unit body

A technology for EMUs and car bodies, applied to railway car bodies, parts of railway car bodies, transport passenger cars, etc. It can solve problems such as poor structural strength, poor sealing, and poor sound insulation performance of inspection doors, and affect driving safety, so as to improve safety , Improve bearing strength and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

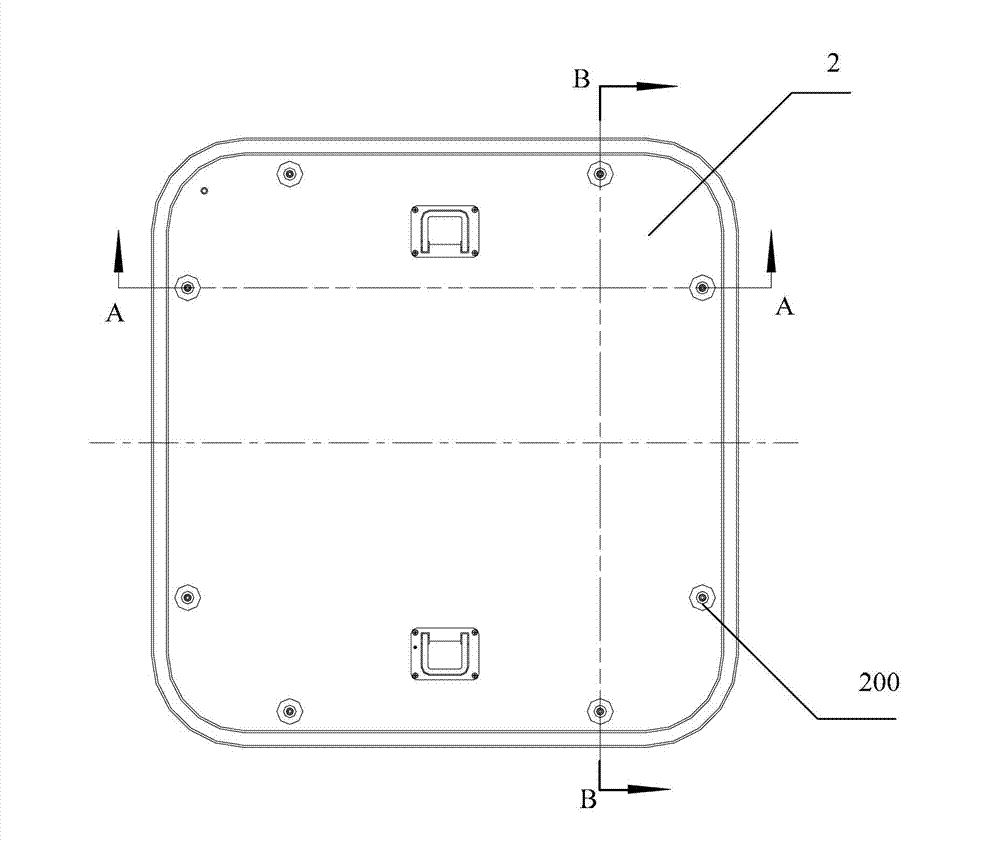

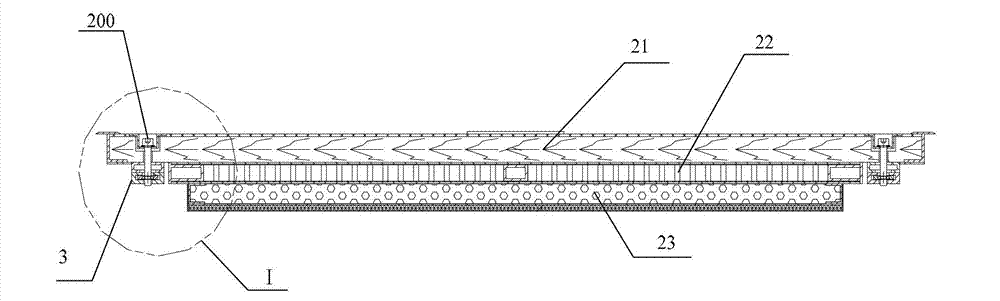

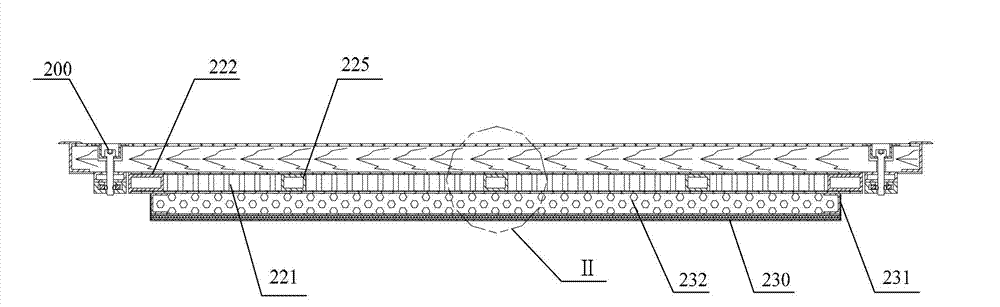

[0019] figure 1 It is a top view of the inspection door in the embodiment of the railway vehicle body of the present invention; figure 2 for figure 1 A-A sectional view; image 3 for figure 1 Middle B-B sectional view; Figure 4 for figure 2 Enlarged view of middle part I; Figure 5 for figure 2 Enlarged view of middle II; Figure 6 It is a top view of the passenger compartment floor in the embodiment of the railway vehicle body of the present invention; Figure 7 for Figure 6 Middle C-C sectional view; Figure 8 for Figure 7 Enlarged view of middle Ⅲ; please refer to Figure 1-8 , this embodiment provides an EMU car body, including: an underframe 10 and a power system module (not shown) suspended below the underframe 10; Opening 11, on the top surface of the chassis 10 and around the inspection opening 11 is covered with a passenger compartment floor 12, and also includes an inspection door 2 for blocking the inspection opening 11. The inspection door 2 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com