Preparation method of sodium hypochlorite

A sodium hypochlorite and chlorine gas technology, applied in the direction of hypochlorous acid, hypochlorite, etc., can solve the problems of frequent sampling times, fast reaction speed, and easy overchlorination, so as to save time and detection costs, and eliminate worries and worries. The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The derivation and formation process of the formula is as follows:

[0014] According to the requirements of the national standard GB19106-2003, the sodium hypochlorite solution should meet the requirement of free alkali % (calculated as NaOH) = 0.1~1.0, and the free alkali analysis and calculation method refer to the standard 5.2.

[0015] 1.1 The relationship between free base and sodium hypochlorite solution qualified

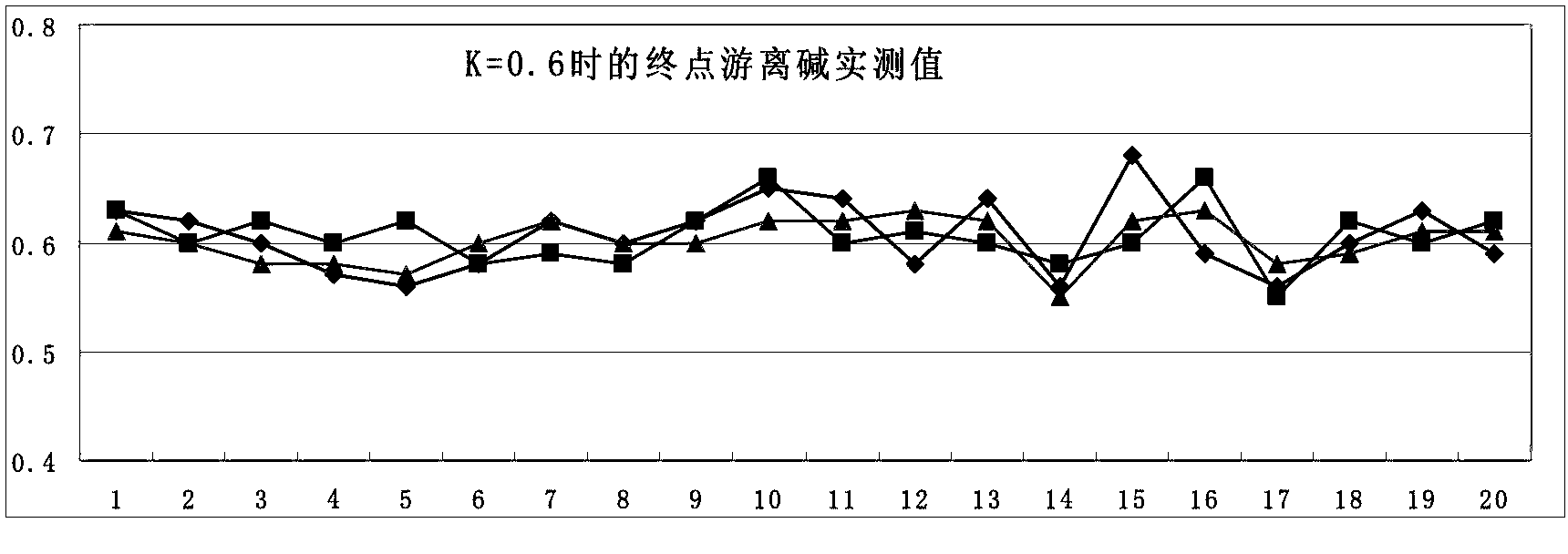

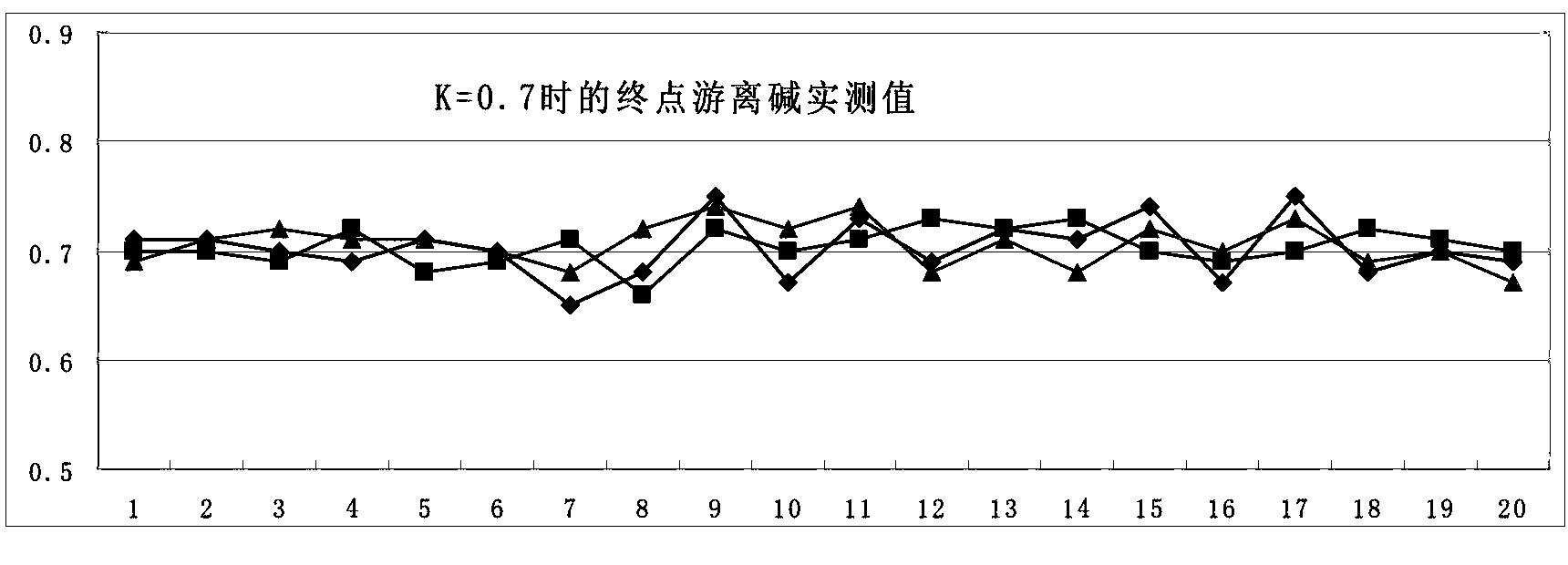

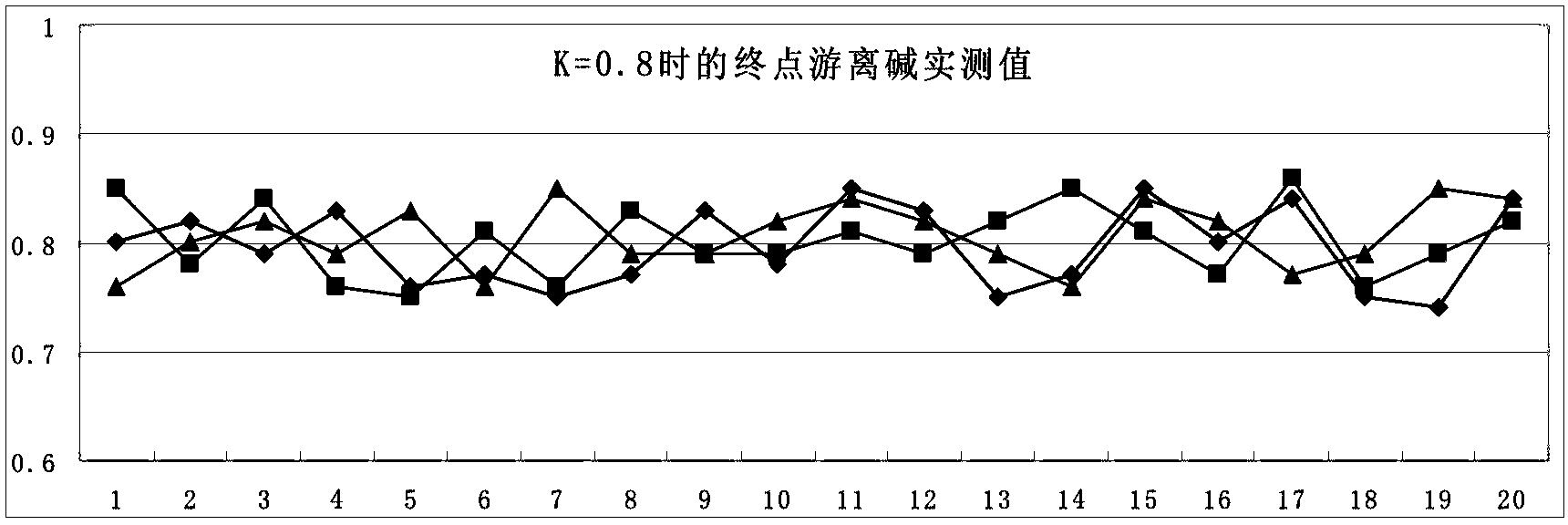

[0016] The following data are several sets of data about the liquid level of the reaction tank and the content of free alkali obtained at different times, different reaction tanks, and different initial liquid levels. The liquid level here refers to the ratio of the height of the reaction tank reached by the reaction liquid to the height of the tank body of the reaction tank (ie volume ratio). And the concentration of free alkali refers to the mass percent content of free alkali.

[0017] Free alkali content at different liquid levels in table 1

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com