Bridge space radioactive concrete-filled steel tube bridge pier and construction method thereof

A radioactive steel pipe and concrete technology, applied in bridge construction, bridges, bridge parts, etc., can solve the problems of low shear bearing capacity of concrete slabs, poor heat and sound insulation effect, and unclear force on the bottom plate, so as to achieve convenient and efficient construction. , Occupy small urban space, reduce the effect of pipeline relocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

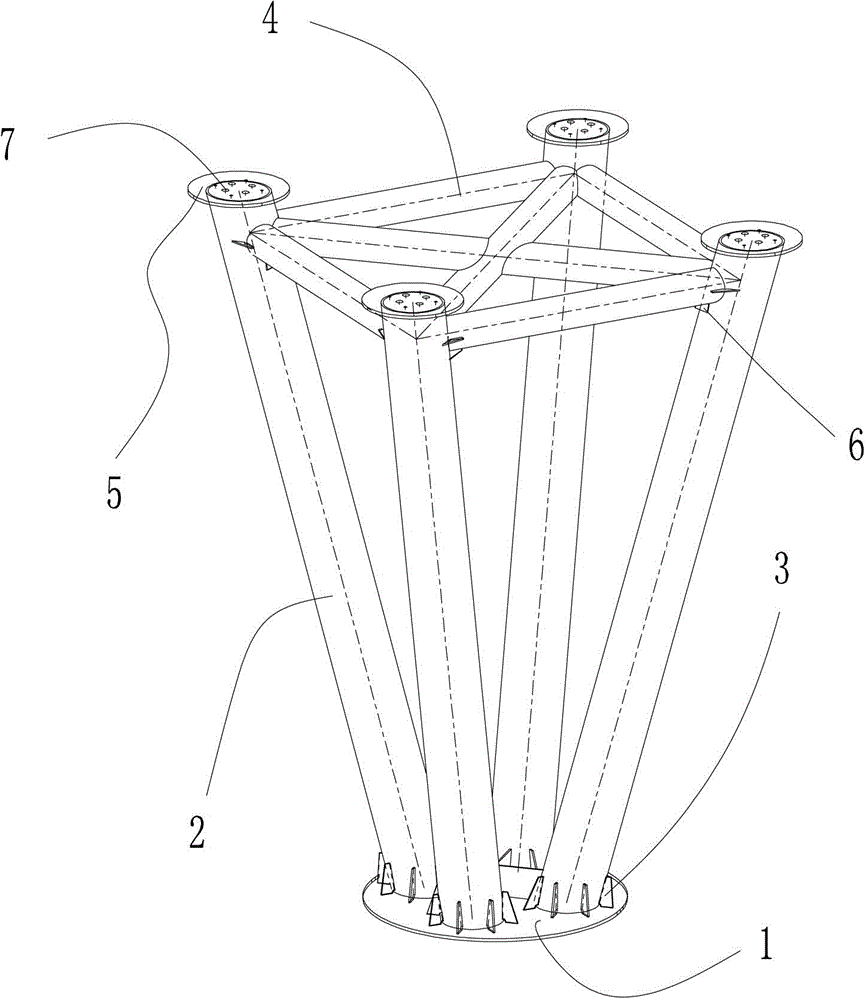

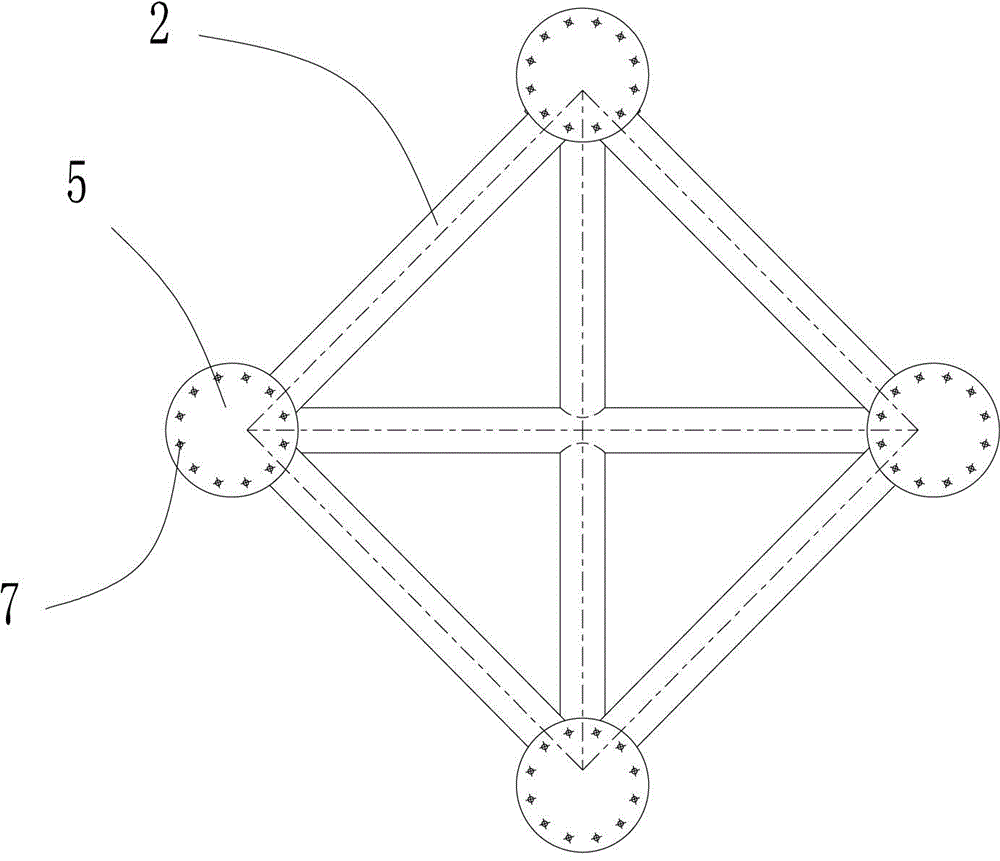

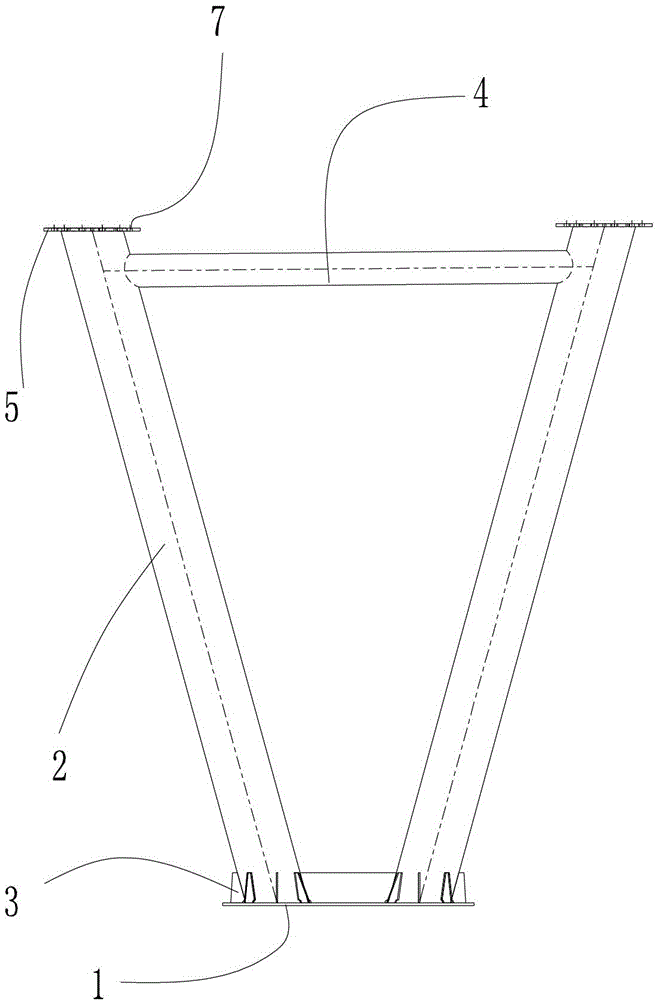

[0030] See Figure 1 to Figure 5 , the present invention relates to a radioactive steel pipe concrete bridge pier in bridge space, and its preferred embodiment includes a flange plate 1, several pier bottom stiffeners 3, four pier support beams 2, six connecting beams 4, four pier top anchor plates 5 and Several contact beam stiffeners6.

[0031] The top surface of the flange 1 is provided with four mounting positions evenly distributed along the circumferential direction.

[0032] The bottom walls of the four pier support beams 2 are respectively installed on the four installation positions on the flange plate 1, and a number of piers evenly arranged in the circumferential direction are welded between the lower end of each pier support beam 2 and the top surface of the flange plate 1 Bottom stiffener 3. The supporting beams 2 of the four piers f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com