Supercritical carbon dioxide fracturing method and supercritical carbon dioxide fracturing system

A carbon dioxide and supercritical technology, applied in the field of shale fracturing, can solve the problems of complex fracturing fluid recovery process, fracturing fluid that cannot be directly recovered, and reduction of porosity and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

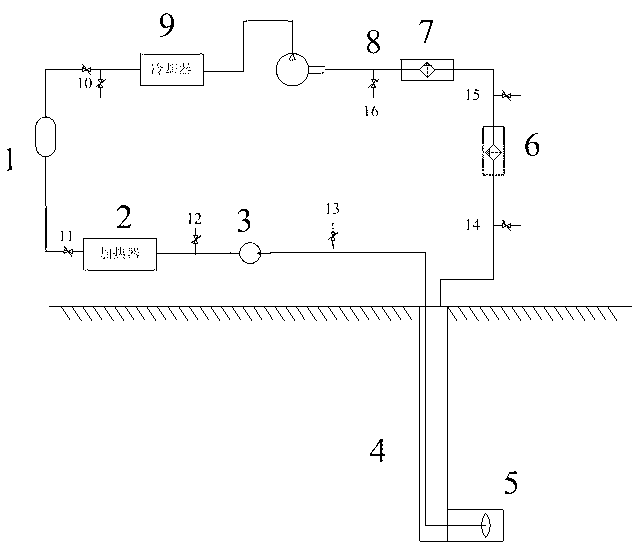

[0019] like figure 1 As shown, the system has a storage tank 1, a booster pump 2, a heater 3, a solid separator separation 6, a liquid separator 7, an air compressor 8, a cooler 9 and a control valve. The output port of the storage tank 1 passes through the pipeline The heater 2 and the booster pump 3 are connected in sequence, the output pipeline of the booster pump 3 extends into the wellbore 4 to the fracturing site 5, and the input port of the storage tank 1 is connected to the cooler 9, the air compressor 8, the liquid The separator 7 is separated from the solid separator 6, and the input pipeline of the solid separator 6 extends into the wellbore 4 to the fracturing site 5, forming a cycle. Control valves 10 are provided on the connecting pipelines between the above components, and control valves 10 are also provided on the pipelines from the booster pump 3 to the fracturing site, and on the pipeline from the solid separator separation 6 to the fracturing site.

[0020]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com