Automatic control device for heating oil tank by using automobile exhaust and automatic control method based on same

An automatic control device and automobile exhaust technology, which is applied in the direction of exhaust device, fuel heat treatment device, noise reduction device, etc., can solve the problems that automatic heating control cannot be realized, and achieve high practical value, wide application space, and high feasibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

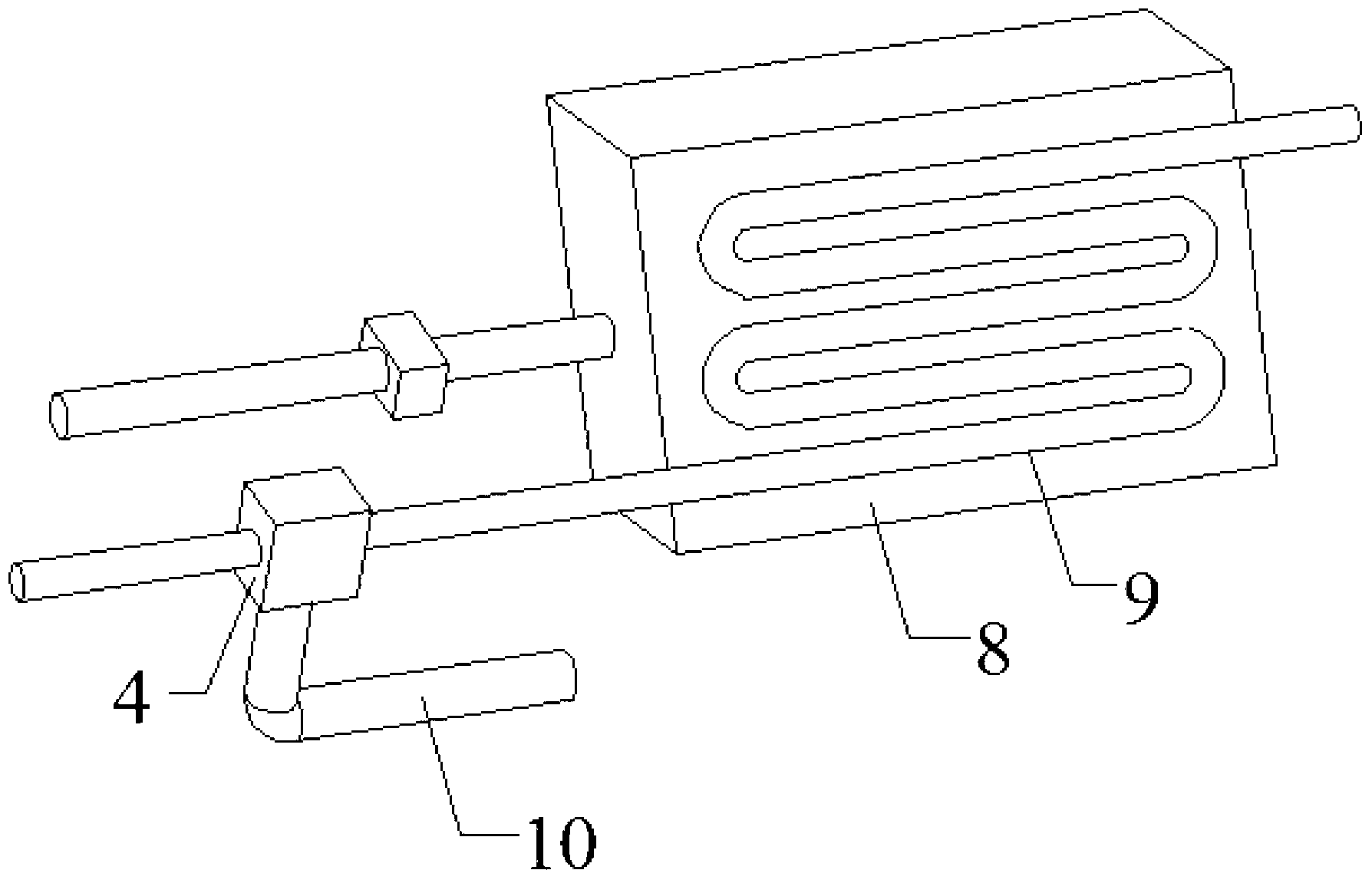

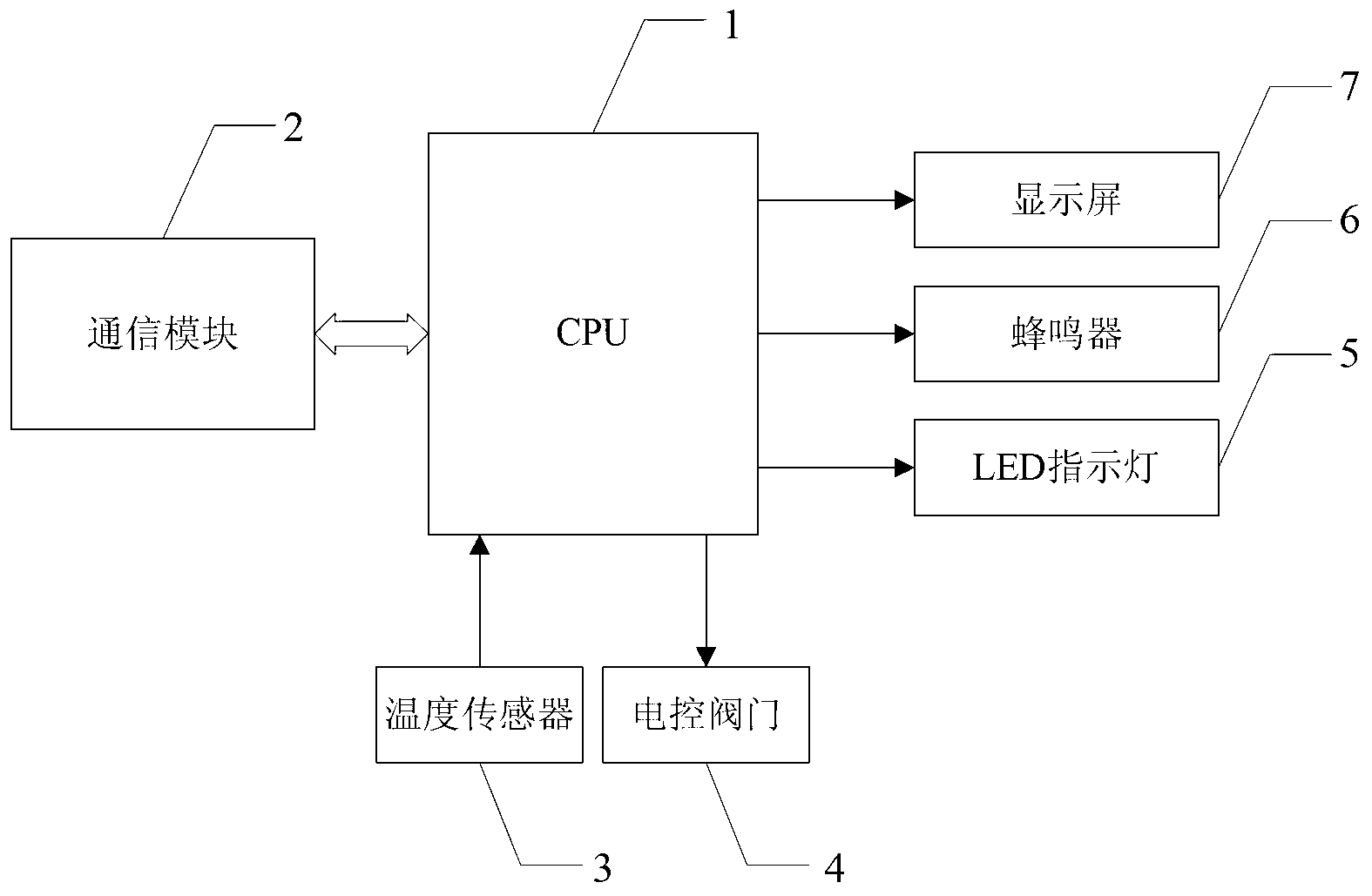

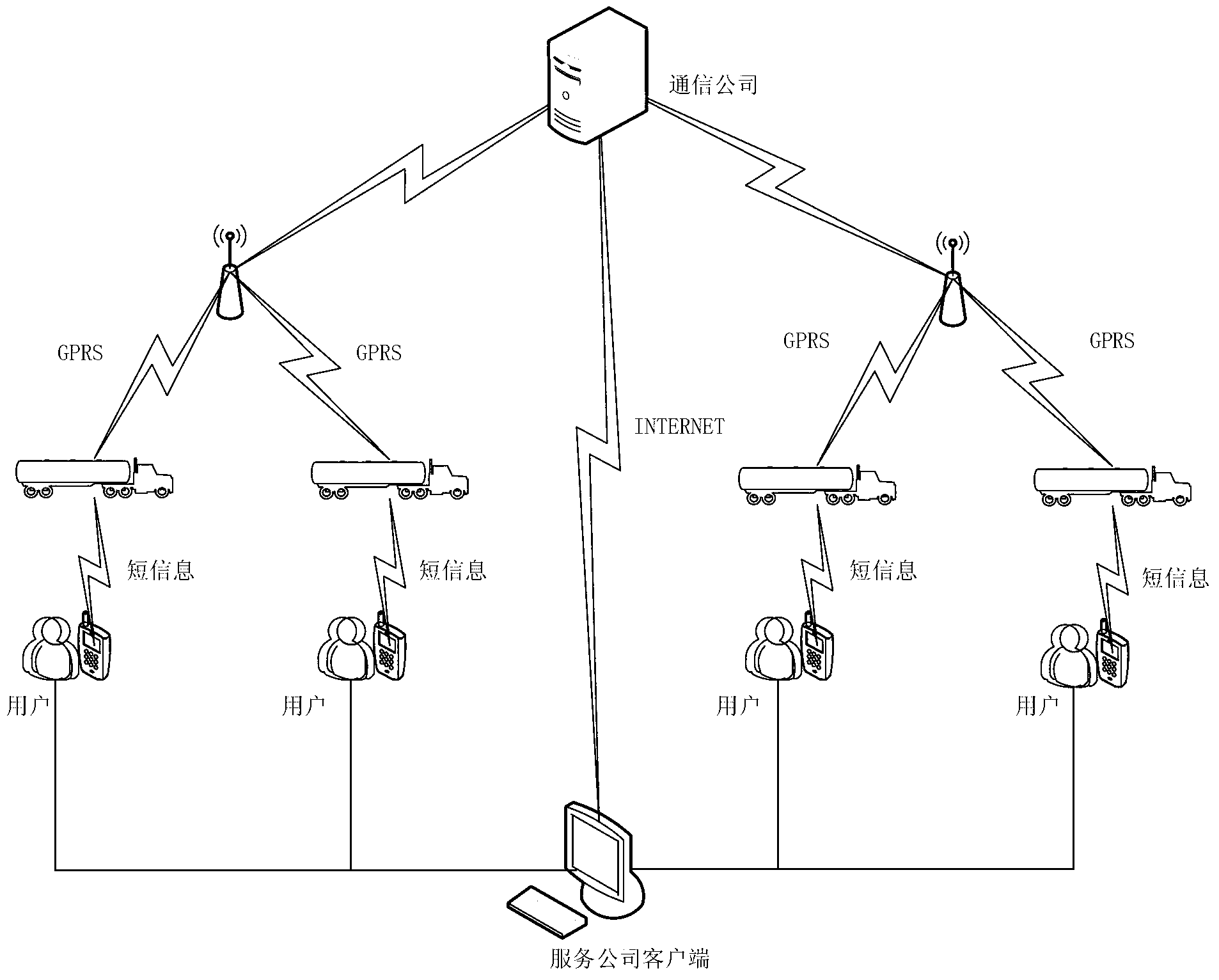

[0035] Specific embodiment one: the following combination figure 1 and figure 2 Illustrating this embodiment, the automatic control device for heating the fuel tank by vehicle exhaust gas described in this embodiment includes an electronically controlled valve 4, a fuel tank 8, a heating pipe 9 and an exhaust gas discharge pipe 10, and the heating pipe 9 is coiled around the bottom of the fuel tank 8, The electronically controlled valve 4 is a three-way structure, one of the three ports of the electronically controlled valve 4 is an automobile exhaust gas inlet, and the other two ports are respectively connected with the air inlet of the heating pipe 9 and the air intake of the exhaust gas discharge pipe 10 . The electric control valve 4 is used to control the communication between the exhaust gas inlet of the automobile and the air inlet of the heating pipe 9, or the communication between the automobile exhaust gas inlet and the exhaust gas discharge pipe 10;

[0036] It al...

specific Embodiment approach 2

[0040] Specific embodiment two: the following combination figure 2 This embodiment is described. This embodiment further describes the first embodiment. The CPU1 is implemented by a single-chip microcomputer, and the model of the single-chip microcomputer is STC12C5A60S2.

specific Embodiment approach 3

[0041] Specific embodiment three: the following combination figure 2 This embodiment will be described. This embodiment will further describe Embodiment 1. The temperature sensor 3 is implemented by using DS18B20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com