Mechanical energy accumulator for a vehicle

An accumulator and mechanical technology, applied in the direction of controlling mechanical energy, mechanical equipment, vehicle components, etc., can solve the problem that the regeneration mechanism cannot cause satisfactory energy regeneration and energy storage, and achieve the effect of increasing the moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

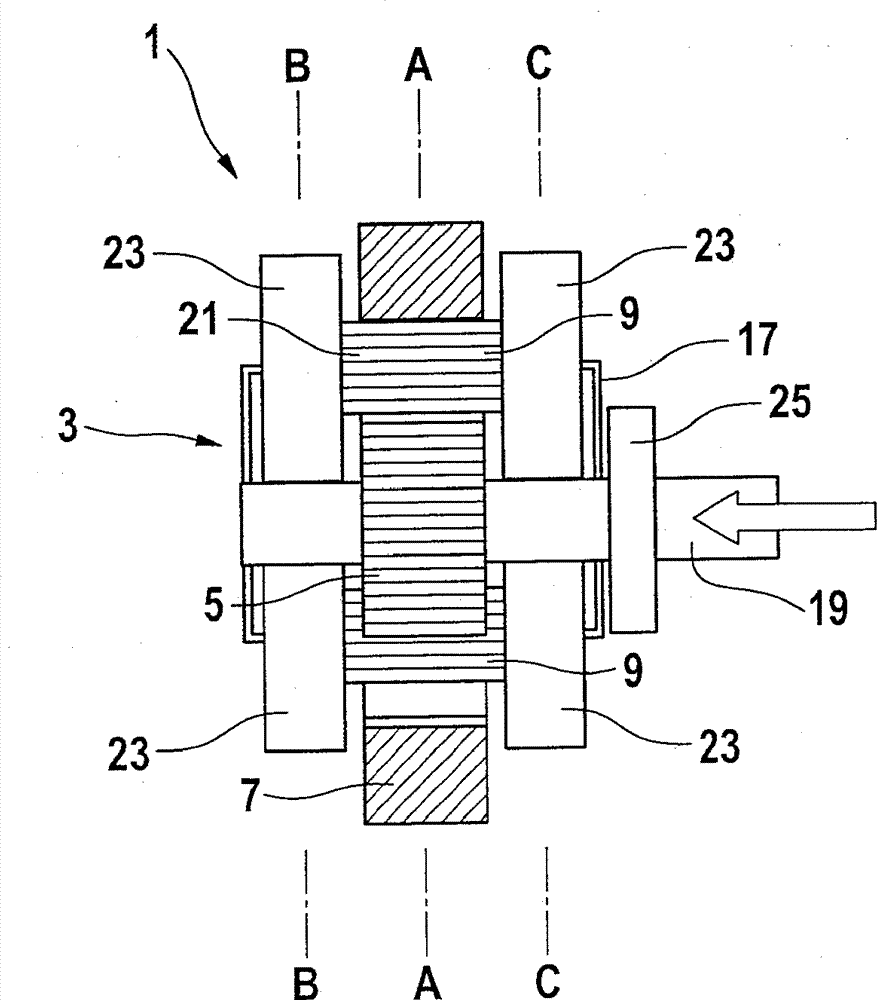

[0039] figure 1 and figure 2 The mechanical energy store according to the invention is shown in side view and in section. Here, the accumulator according to the invention can be used in electric or hybrid vehicles, as it is schematically shown in Figure 4 as shown in.

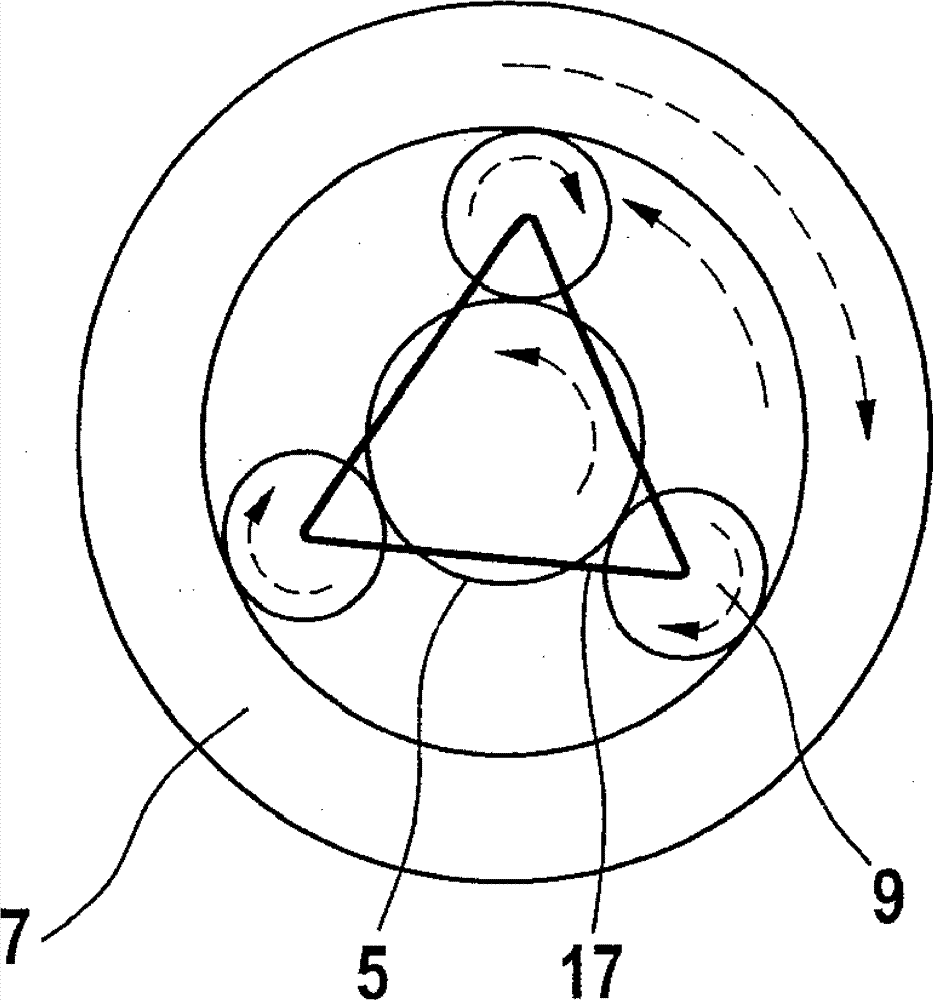

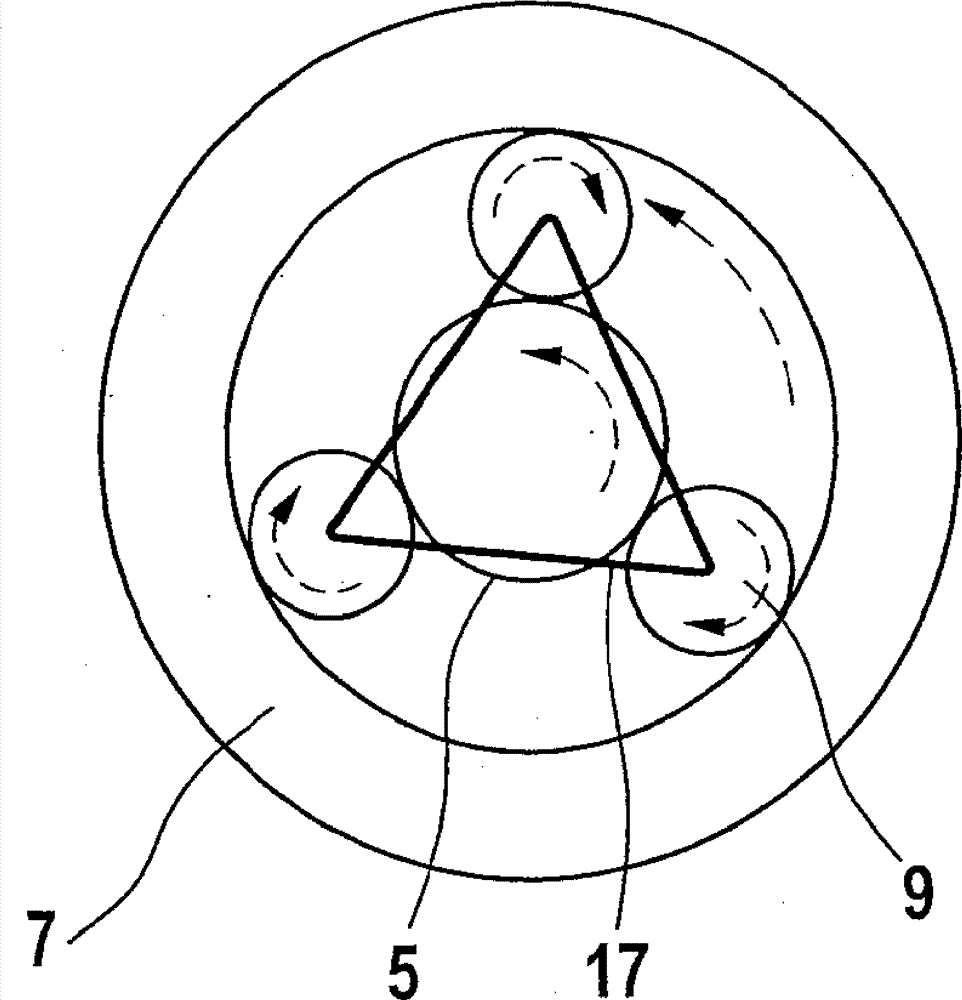

[0040] The energy store 1 has a planetary gear 3 . The planetary gear 3 has a central sun gear 5 , an external gear 7 and three planetary gears 9 arranged between the sun gear 5 and the external gear 7 . On the outer circumference of the sun gear 5 and on the inner circumference of the external gear 7, teeth are respectively provided (in figure 1 not shown in ), into which the teeth of the planetary gears 9 mesh, so that the rotation of the sun gear 5 or the outer gear 7 causes a corresponding rotation and / or movement of the planetary gears 9 . The sun gear 5 is connected to the motor 11 of the vehicle 13 (see Figure 4 ) cannot be connected relative to rotation. The external gear 7 is non-rotatably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com