Trench gate power semiconductor device and method for manufacturing same

A technology of power semiconductors and trench gates, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc. On-resistance, high reverse withstand voltage, and the effect of increasing impurity concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0040] 1. Trench gate power semiconductor device 100 of Embodiment 1

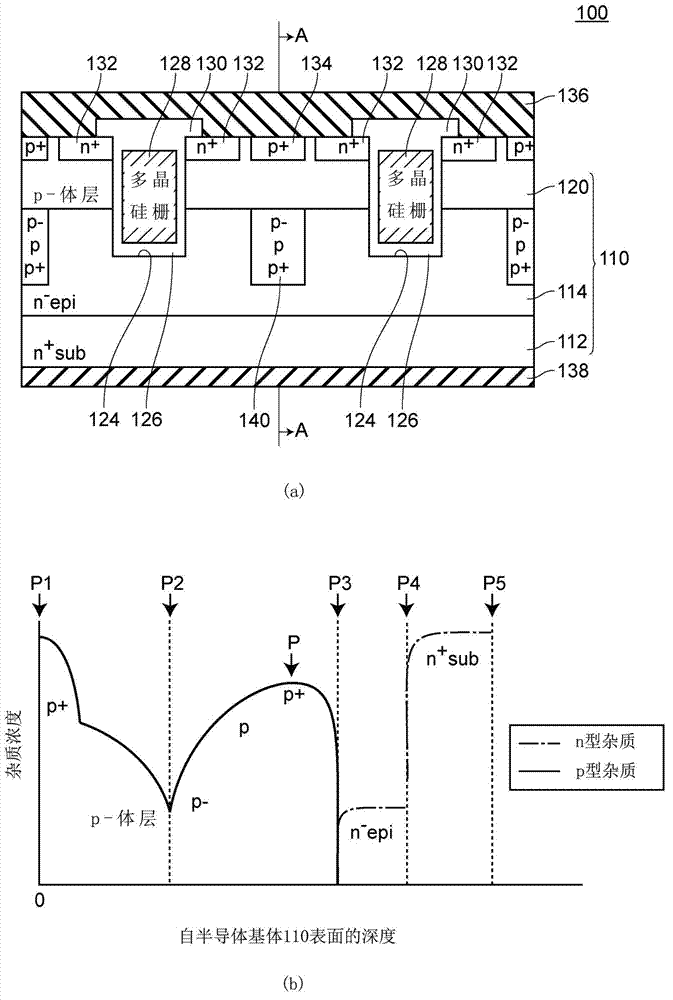

[0041] figure 1 It is an explanatory diagram showing the trench gate power semiconductor device 100 according to the first embodiment. figure 1 (a) is a cross-sectional view showing the trench gate power semiconductor device 100, figure 1 (b) is a schematic diagram showing concentration distributions of p-type impurities and n-type impurities in the trench gate power semiconductor device 100 .

[0042] Such as figure 1 As shown in (a), the trench gate power semiconductor device 100 of Embodiment 1 is a trench gate power MOSFET, which has: n -type drift layer 114; the p-type body layer 120 located on the drift layer 114; the body layer 120 is opened to reach the groove 124 formed by the drift layer 114; it is arranged in the body layer 120, and at least a part is placed on the inner periphery of the groove 124 n + type source region (first semiconductor region) 132; the gate insulating film 126 for...

Embodiment approach 2

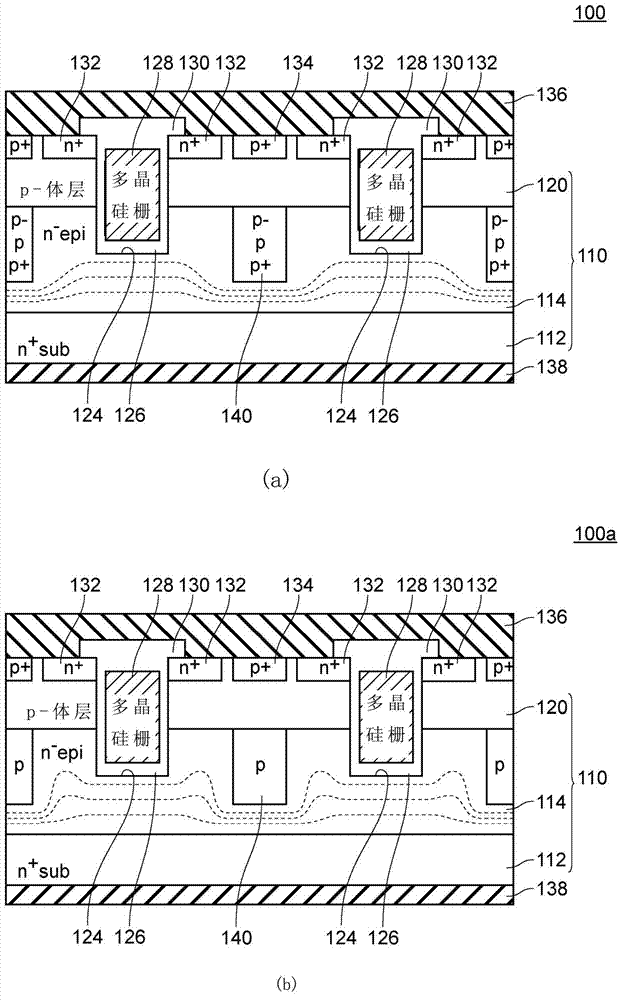

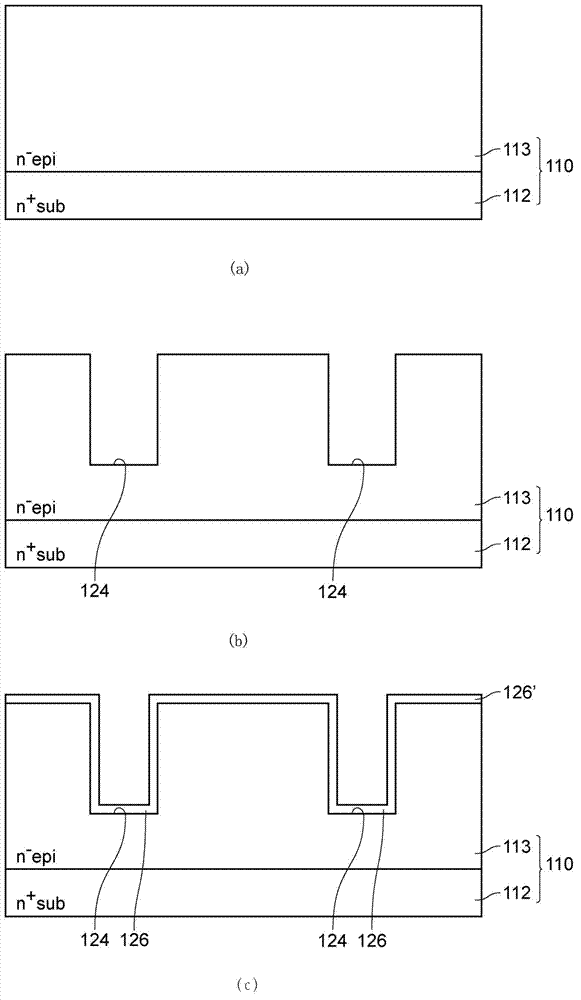

[0084] Figure 8 It is an explanatory diagram showing the trench gate power semiconductor device 102 according to the second embodiment. Figure 8 (a) is a cross-sectional view showing the trench gate power semiconductor device 102, Figure 8 (b) is a schematic diagram showing the concentration distribution of p-type impurities and n-type impurities in the trench gate power semiconductor device 102 . Figure 9 It is an explanatory diagram showing a method of manufacturing trench gate power semiconductor device 102 according to the second embodiment. Figure 9 (a)~ Figure 9 (c) is a schematic diagram showing the main works. in addition, Figure 9 (a) is with Figure 5 (a) The corresponding graph, Figure 9 (c) is with Figure 5 (b) Corresponding plot.

[0085] The trench gate power semiconductor device 102 of the second embodiment basically has the same structure as the trench gate power semiconductor device 100 of the first embodiment, but as Figure 8 As shown in FI...

Embodiment approach 3

[0091] Figure 10 It is a cross-sectional view showing the trench gate power semiconductor device 104 according to the third embodiment. The trench gate power semiconductor device 104 of the third embodiment basically has the same structure as the trench gate power semiconductor device 100 of the first embodiment, but the depth position of the bottom surface of the trench 124 is the same as that of the trench gate power semiconductor device of the first embodiment. The power semiconductor device 100 is different. That is, in the trench gate power semiconductor device 104 of the third embodiment, as Figure 10 As shown, the depth of the bottom of the groove 124 is deeper than the depth between the bottom of the bulk layer 120 and the bottom of the drift layer 114 .

[0092] In this way, although the trench gate power semiconductor device 104 of the third embodiment has a depth position of the bottom surface of the trench 124 that is different from the trench gate power semico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com