Automatic horizontal boring and milling machine

A milling and boring machine, horizontal technology, applied in the field of automatic horizontal milling and boring machines, can solve the problems of low processing efficiency, machine axis can not be automatically positioned, cumbersome operation, etc., to improve reliability, reduce machine failure rate, and simplify the operation process requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

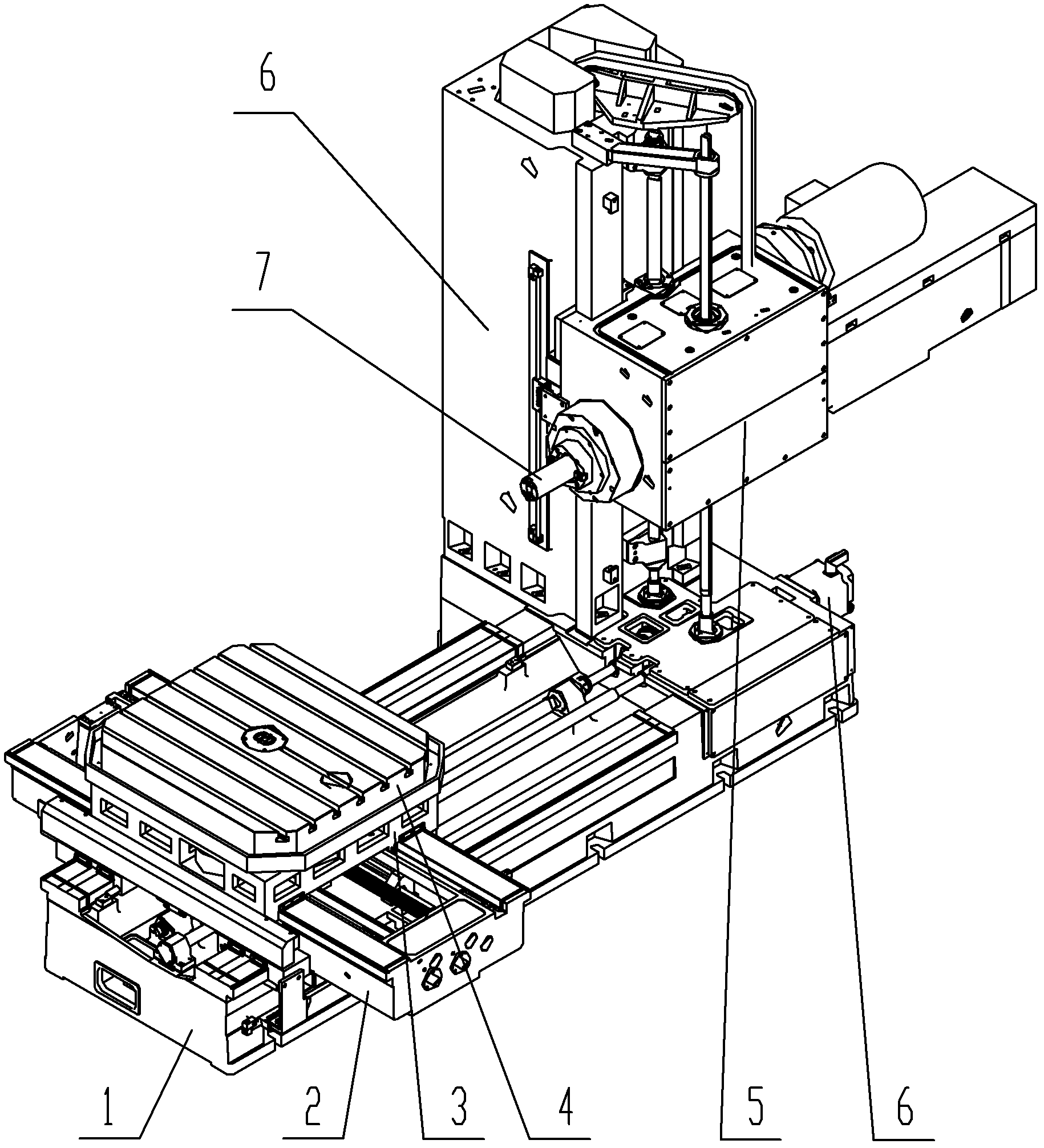

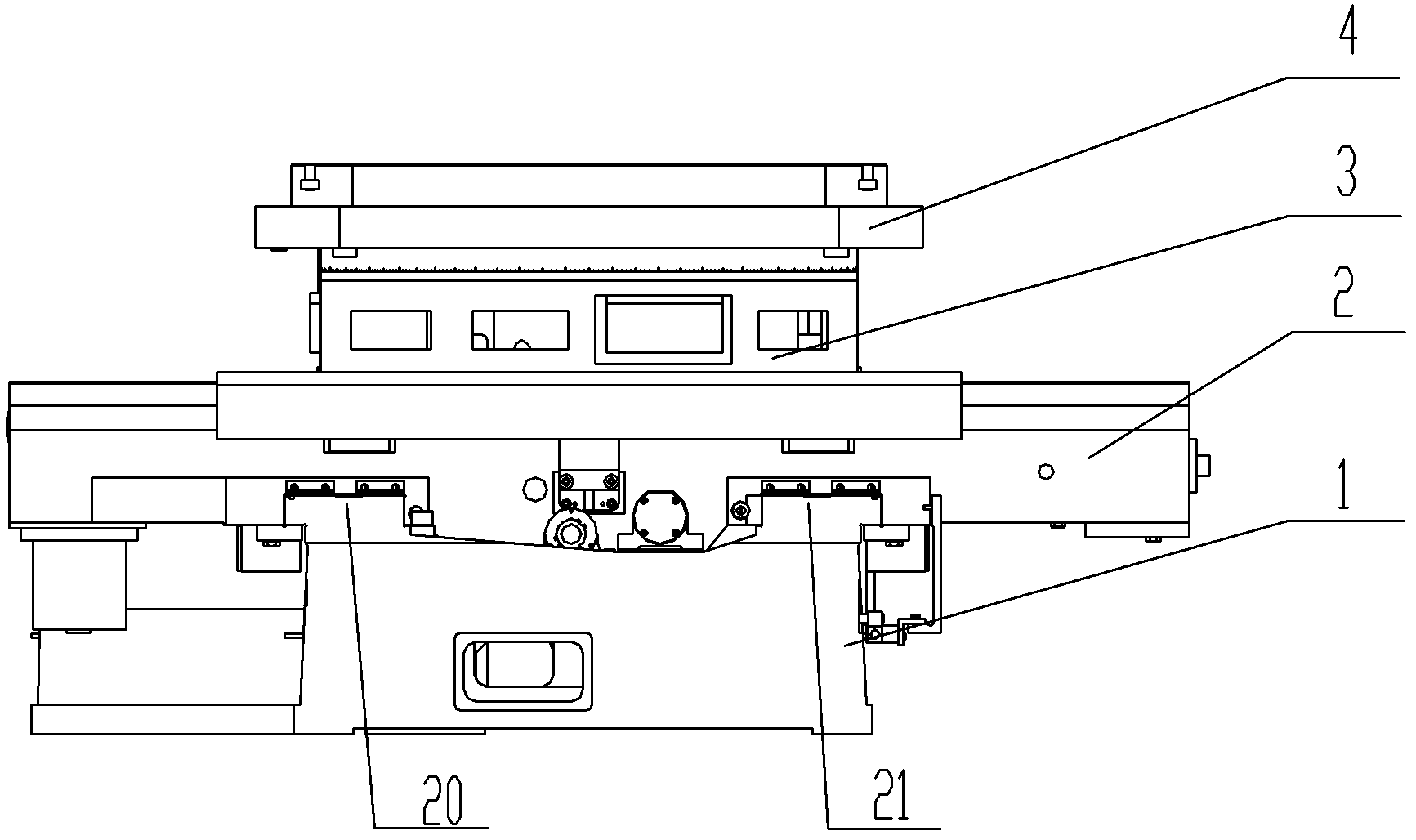

[0028] AH90 automatic horizontal milling and boring machine, including bed 1, lower slide 2, upper slide 3, worktable 4, spindle box 5, column 6, boring shaft 7, feed servo motor 8 and electrical system, such as figure 1 As shown, the column 6 is fixed on the bed 1, the spindle box 5 is installed on the column 6, and the spindle box 5 can move up and down on the column 6 (Y-axis movement); the sliding seat 2 is installed on the guide rail of the bed 1, The lower seat 2 can move longitudinally on the bed 1 (Z-axis movement); the upper slide 3 is installed on the lower seat 2, and the upper slide 3 can move laterally on the lower seat 2 (X-axis movement); the workbench 4 is installed on the upper slide 3, the workbench 4 can rotate on the upper slide 3 (B-axis movement), the feed motor 8 is installed on the bed 1, the boring shaft 7 is in the headstock 5, and can be Telescoping (W-axis movement) in the headstock 5. In the main shaft box 5, there is a main shaft variable speed t...

Embodiment 2

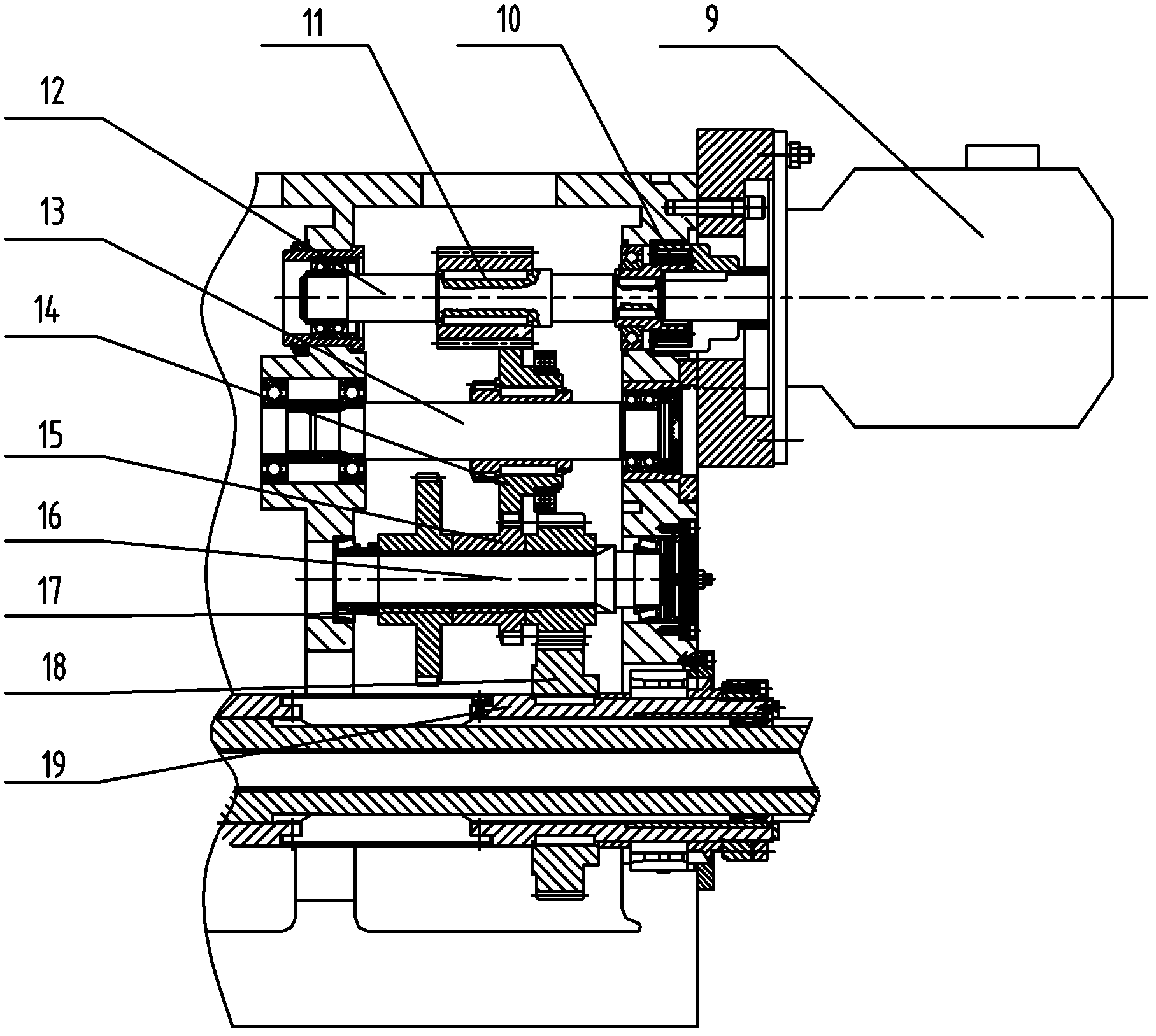

[0040] An automatic horizontal milling and boring machine (we call it AH90 automatic horizontal milling and boring machine), the automatic horizontal milling and boring machine is specifically composed of the following parts: bed 1, lower slide 2, upper slide 3, working Table 4, spindle box 5, column 6, boring shaft 7, feed servo motor 8, guide rail, electrical system; wherein: the lower slide 2 is arranged on the bed 1, the upper slide 3 is arranged above the slide 2 and both Connected together; the workbench 4 is arranged on the upper slide 3; a feed servo motor 8 and a column 6 are provided at the proximal end of the horizontally arranged bed 1, and the vertically arranged column 6 is distributed near the bed 1 The proximal end of that end of the box 9 is arranged; the spindle box 5 is arranged on the column 6 and can move up and down relative to the column 6; the boring shaft 7 is arranged on the spindle box 5 and its axial direction is arranged along the horizontal directi...

Embodiment 3

[0051] The content of this embodiment is basically the same as that of Embodiment 2, and its difference mainly lies in:

[0052] 1) The workbench clamping mechanism provided between the upper sliding seat 3 and the workbench 4 adopts other clamping and anti-loosening gap adjustment structures.

[0053] 2) The basic functions of the electrical system described above are similar to those in Embodiment 2, but other specific configurations are selected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com