Silk-screen printing machine based on CCD (charge coupled device) automatic alignment printing system

A technology of screen printing machine and printing system, applied in screen printing machine, printing machine, rotary printing machine, etc., can solve the problem of timing confirmation and adjustment of position, waste of production time, neglect of equipment stability, etc. problems, to achieve the effect of shortening the production cycle, saving resources, and enhancing market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

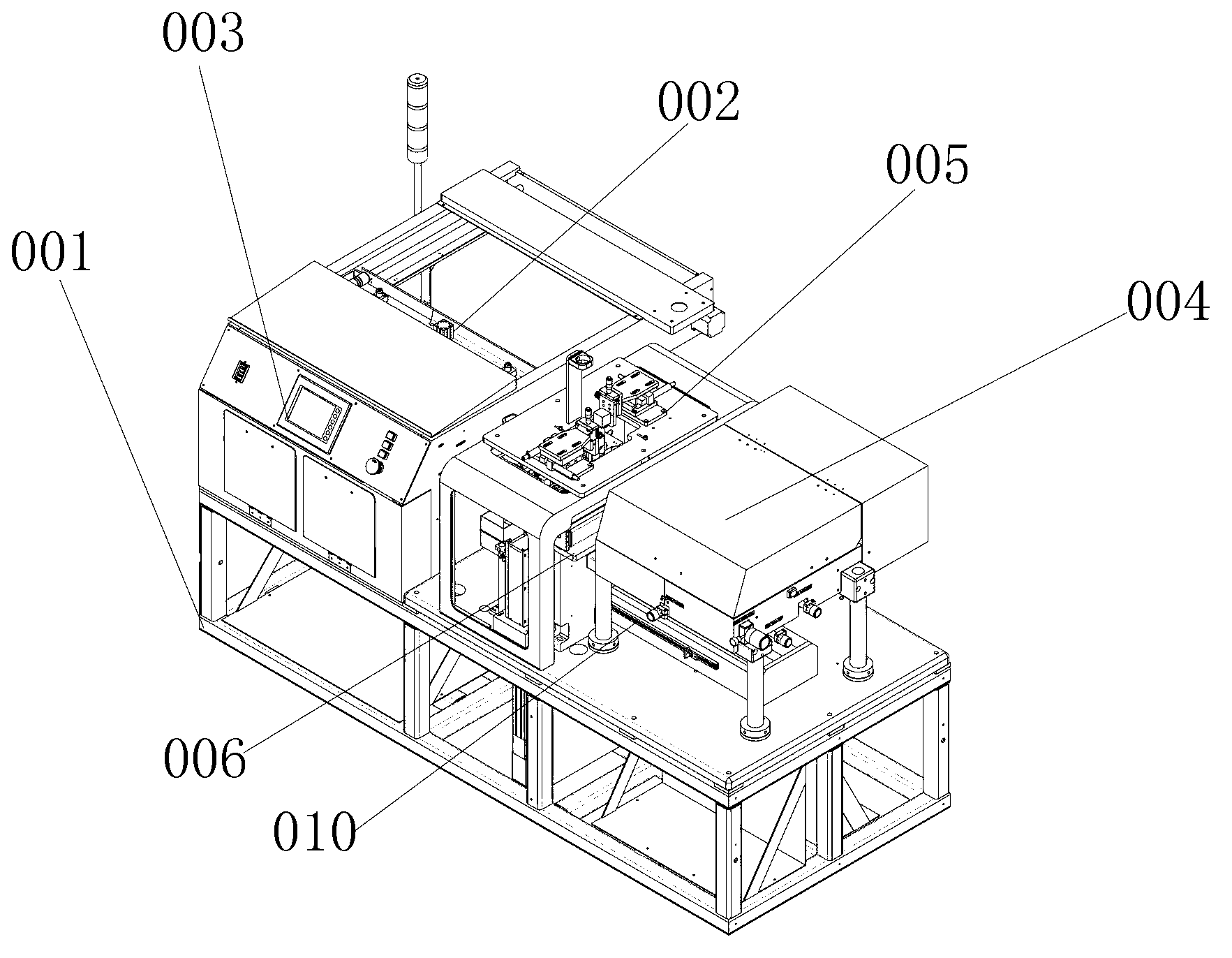

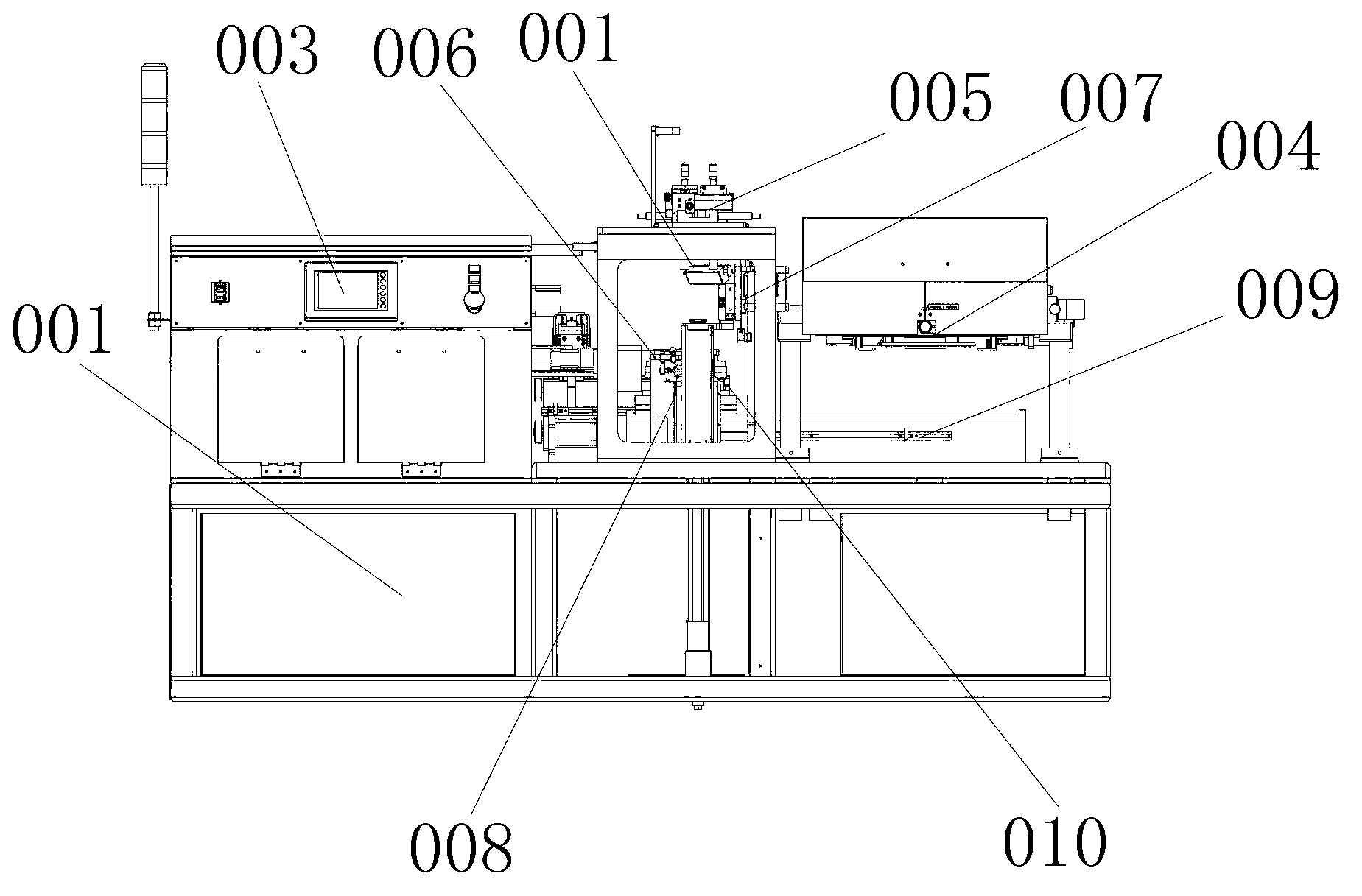

[0020] In this embodiment, part of the composition structure is the general structure of a traditional screen printing machine, and the steps are marked and explained in the accompanying drawings.

[0021] like figure 1 and figure 2 As shown, the screen printing machine based on the CCD automatic alignment printing system in this embodiment includes a mechanical body, which is composed of a frame 001 and an actuator 002 and 003 control devices arranged on the frame 001, wherein, The actuator 002 includes a feeding device 013, a positioning device 012, a transmission device 011 and a printing device 004 for mutual connection, and the control device 003 includes a CCD automatic alignment printing system and a control terminal and a data processing terminal connected thereto. and drive unit.

[0022] The feeding device 013 includes a feeding mechanism and a hand-feeding mechanism, the positioning device 012 includes a pre-positioning mechanism, a vacuum platform 008 and a UVW ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap