Vacuum soaking and drying all-in-one machine

A vacuum impregnation and integrated machine technology, which is applied in the direction of liquid/gas/steam removal by air jet method, liquid/gas/steam yarn/filament treatment, etc., which can solve the problems of high cost of raw silk treatment, increased labor intensity, low work efficiency, etc. problems, to achieve the effects of short soaking time, saving labor costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

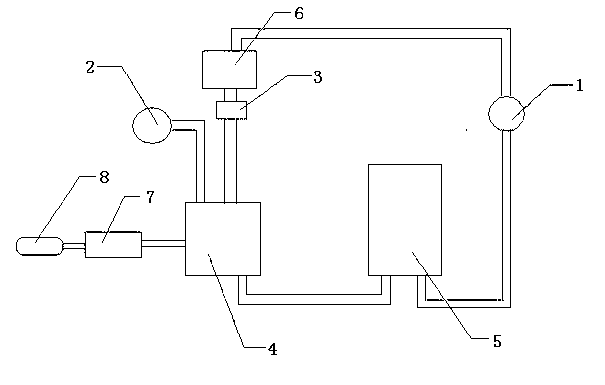

[0012] figure 1 It is a structural schematic diagram of an embodiment of the present invention.

[0013] Such as figure 1 Shown: an integrated vacuum impregnation and drying machine, including a soaking tank 4 , a liquid preparation tank 5 and an emulsion tank 6 . The outlet of the liquid preparation cylinder 5 is communicated with the entrance of the emulsion cylinder 6 through a pipeline, the outlet of the emulsion cylinder 6 is communicated with the entrance of the soaking cylinder 4 through a pipeline, and the outlet of the soaking cylinder 4 is communicated with the entrance of the liquid preparation cylinder 5 through a pipeline, thus, Soaking cylinder 4, liquid preparation cylinder 5 and emulsion cylinder 6 form the circuit of emulsion.

[0014] A water pump 1 is arranged between the liquid preparation tank 5 and the emulsion tank 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com