Garage processor

A technology for garbage disposer and kitchen waste, which is applied to indoor sanitary piping devices, water supply devices, buildings, etc., and can solve the problems of unsatisfactory connection structure between garbage disposer and pool, troublesome operation, inconvenient disassembly and assembly of garbage disposer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

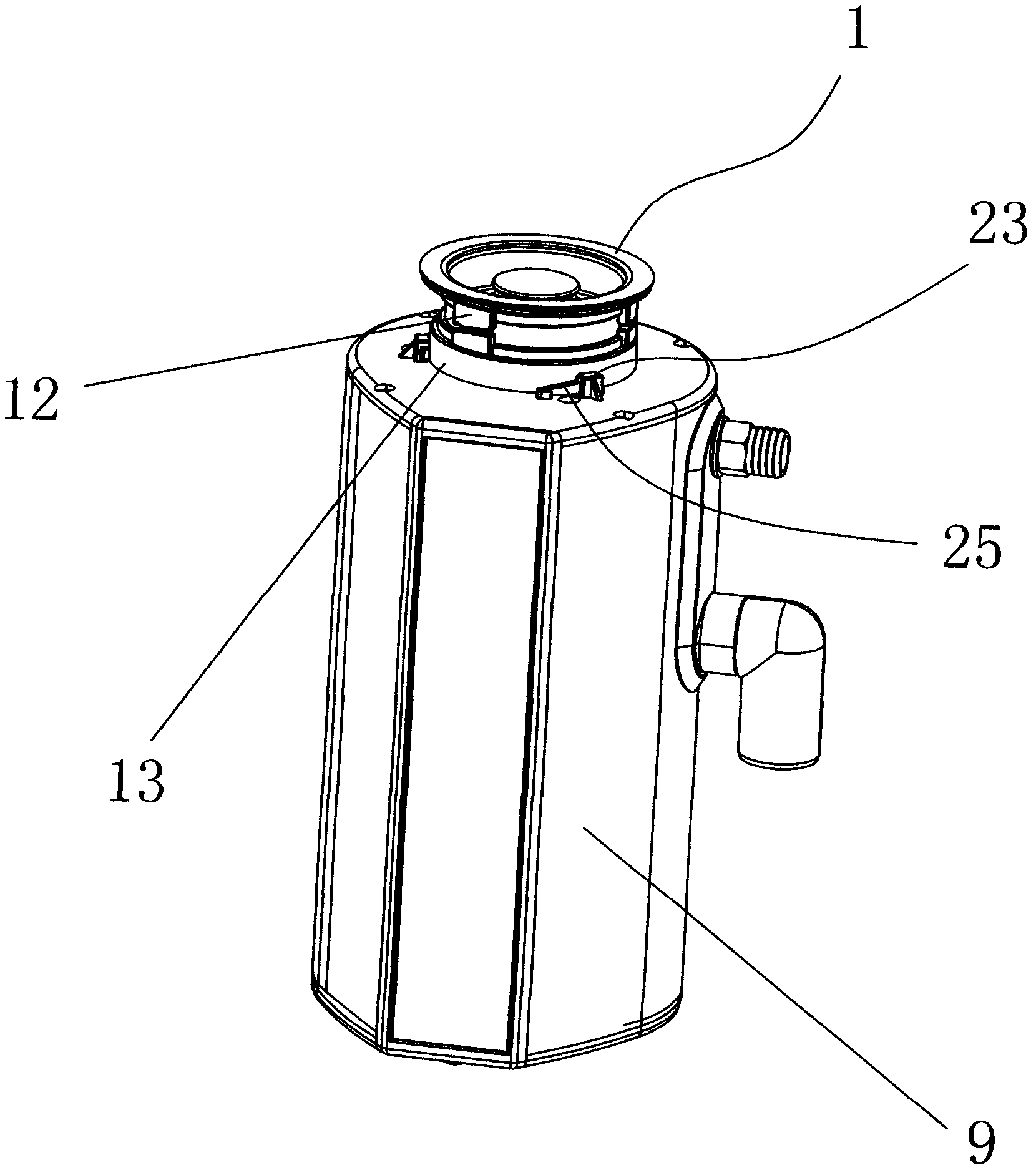

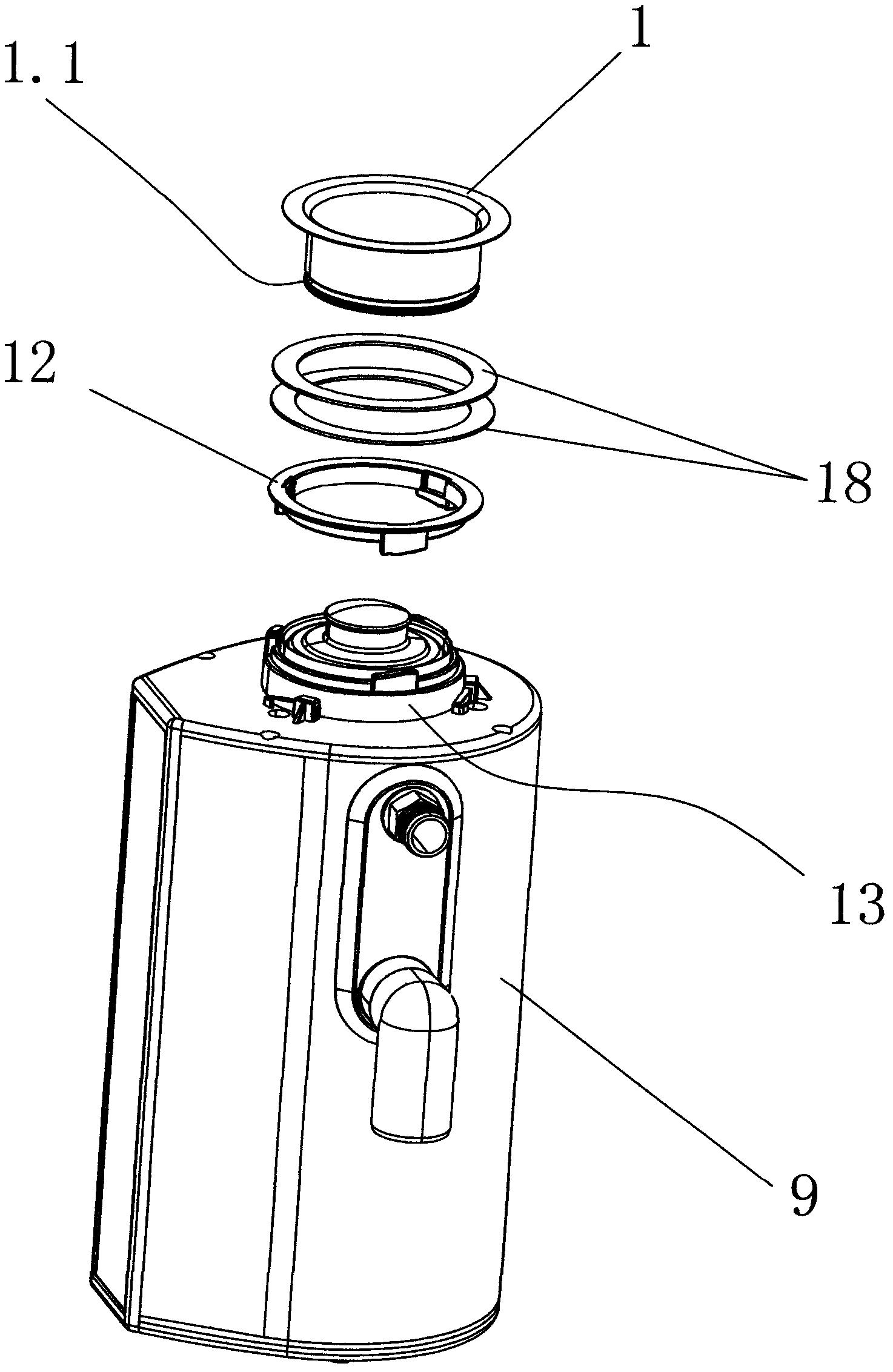

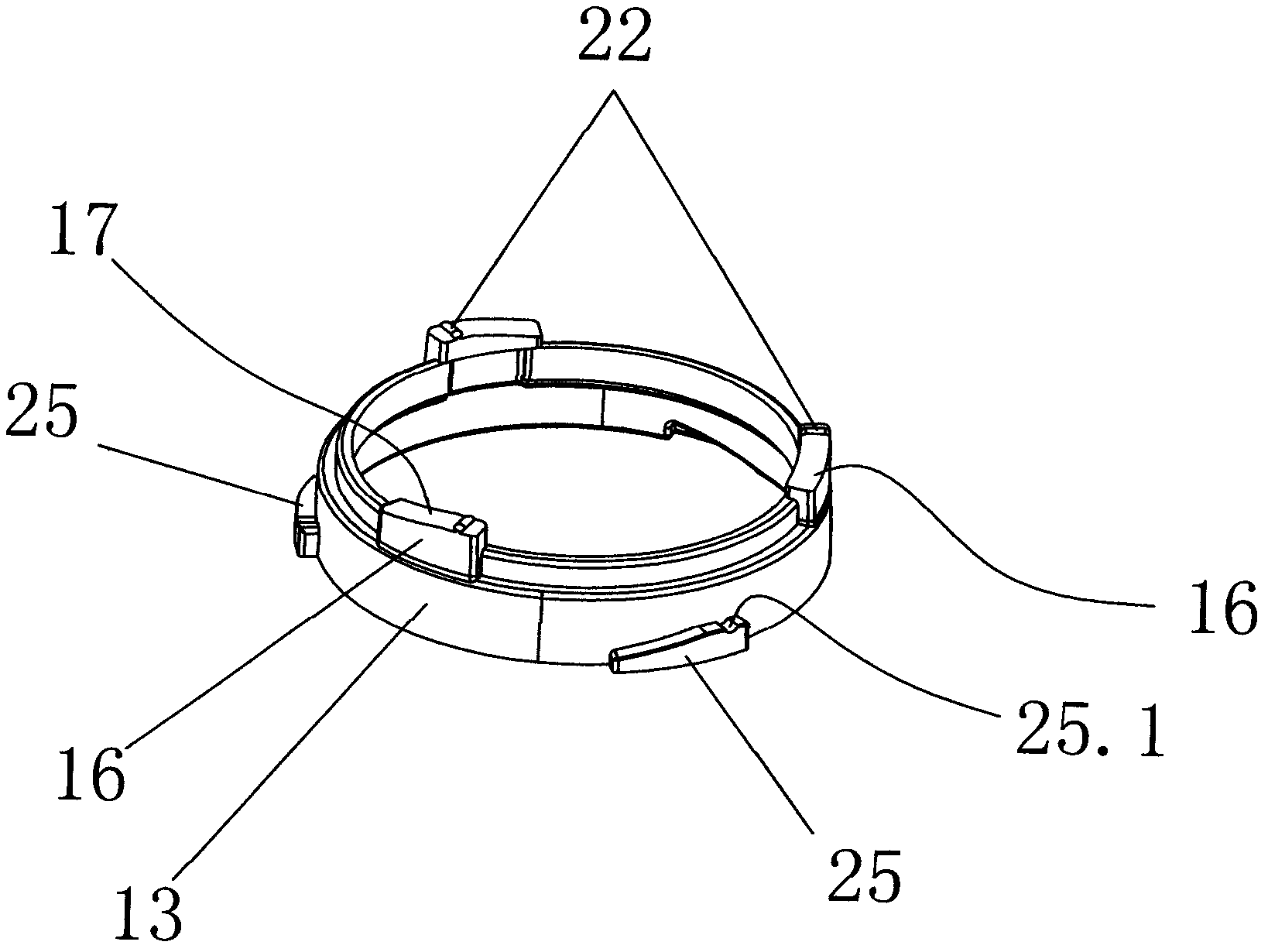

[0044] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 As shown, the garbage disposer of the present invention includes a water leakage port 1, a grinding chamber 2, a driving device 8, and a casing 9. The grinding chamber 2 is provided with a grinding mechanism 3, and the grinding mechanism 3 is mainly composed of a percussion hammer 4, a feeding blade 5, The side blade 6 and the grinding disc are composed; the driving device 8 is a driving motor, and the output shaft of the driving motor is connected with the grinding disc to drive the grinding disc to rotate without playing a protective role. The above-mentioned grinding ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com