Miniature residue-free food-grade brushless direct-current pump

A direct-current water pump with no residue technology, applied to components, pumps, pump devices, etc. of elastic fluid pumping devices, can solve problems affecting food hygiene quality, difficult cleaning, and affecting the service life of water pumps, etc., to achieve convenience and speed Cleaning, high-efficiency heat dissipation, clean and environmentally friendly pump chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

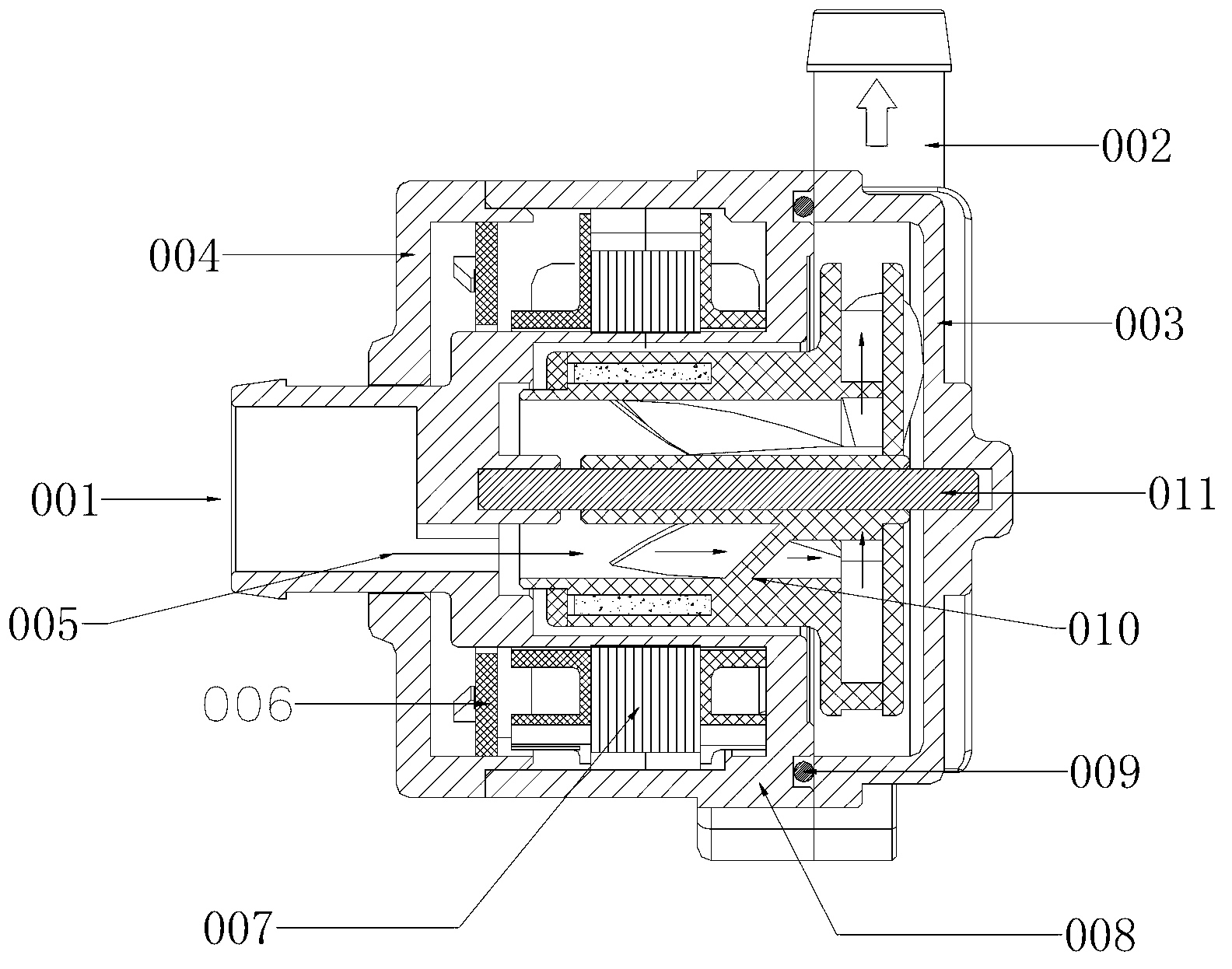

[0021] In this embodiment, the "L" type DC channel is figure 1 The transmission channel along the direction of the arrow in the middle position.

[0022] Such as figure 1 As shown, the miniature non-residue food-grade brushless DC water pump provided in this embodiment includes a water pump main body, the water pump main body includes a pump cover 004 and a pump chamber 008, and the center of the pump chamber 008 is provided with a water flow channel 005 and a driving device. Both ends of the water flow channel 005 are respectively connected to the water inlet 001 and the water outlet 002, and the water inlet 001 and the water outlet 002 are connected to the water flow channel 005 to form an "L"-shaped direct current channel. through the center.

[0023] The driving device is composed of a driving motor, a rotor 010 and a control circuit board 006; the driving motor includes an iron core 007 and a ceramic shaft core 011, and is packaged in the pump chamber 008 through a seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com