Furnace condition optimizing and monitoring device and method using same for optimizing

A monitoring device and furnace condition technology, which is applied in the field of furnace condition automatic optimization monitoring device, can solve the problems of accelerating the gas flow velocity in the furnace, reducing the thermal efficiency of the heating furnace, and the excessive air coefficient is too small, so as to improve the operating efficiency and increase the furnace efficiency , increase the effect of useful work

Active Publication Date: 2013-08-21

SHENZHEN JIAYUNTONG ELECTRONICS

View PDF4 Cites 31 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] 2) The excess air coefficient is too small

[0012] Too small furnace negative pressure may cause tempering and injury accidents; too large furnace negative pressure will accelerate the flow velocity of gas in the furnace, reduce the heat exchange time, and cause the exhaust gas temperature to be too high. In addition, too large furnace negative pressure will also cause Increase the amount of air entering the furnace, thereby increasing the excess air coefficient, resulting in a decrease in the thermal efficiency of the heating furnace

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0047] The present invention will be further described below in conjunction with drawings and embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

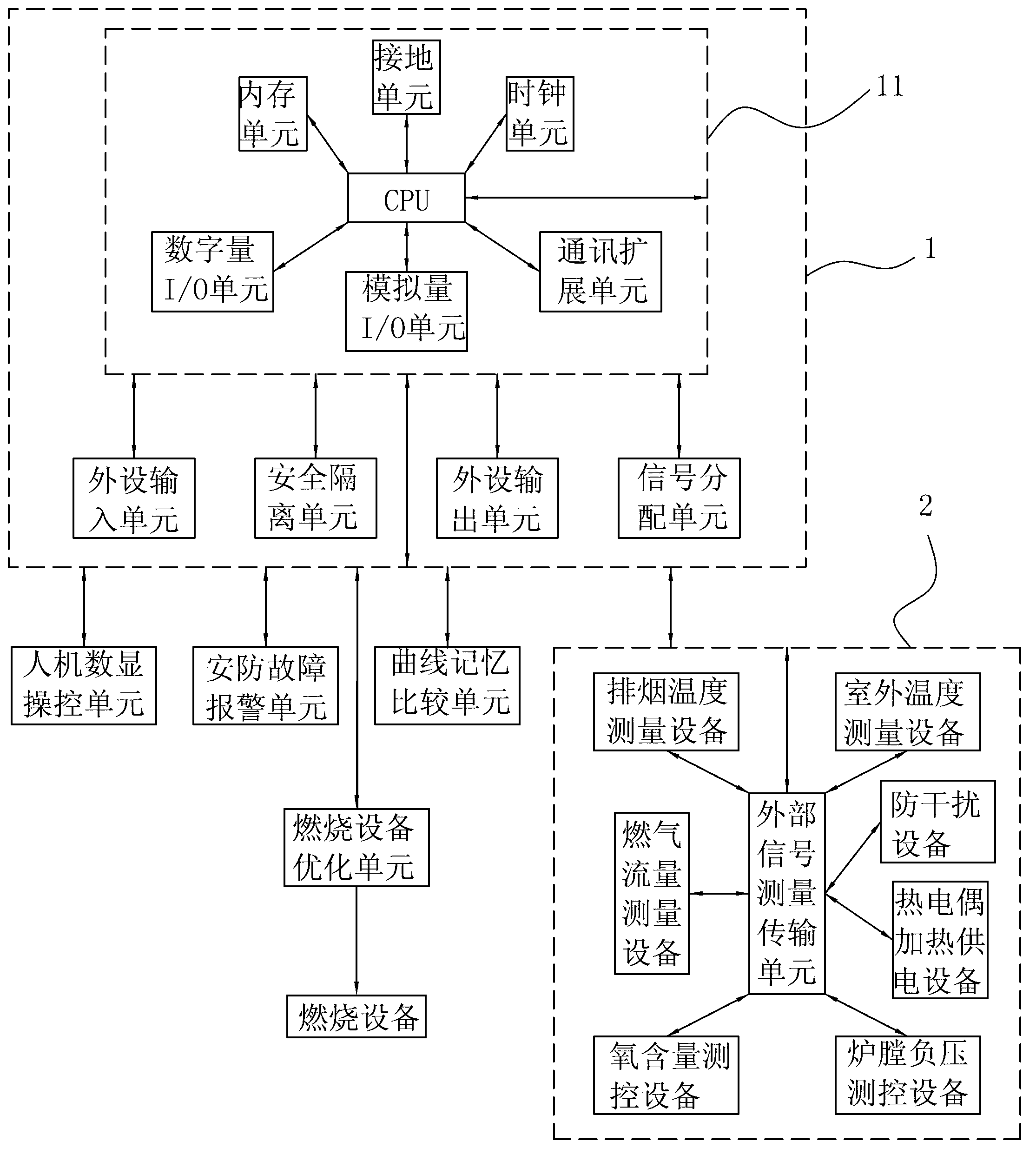

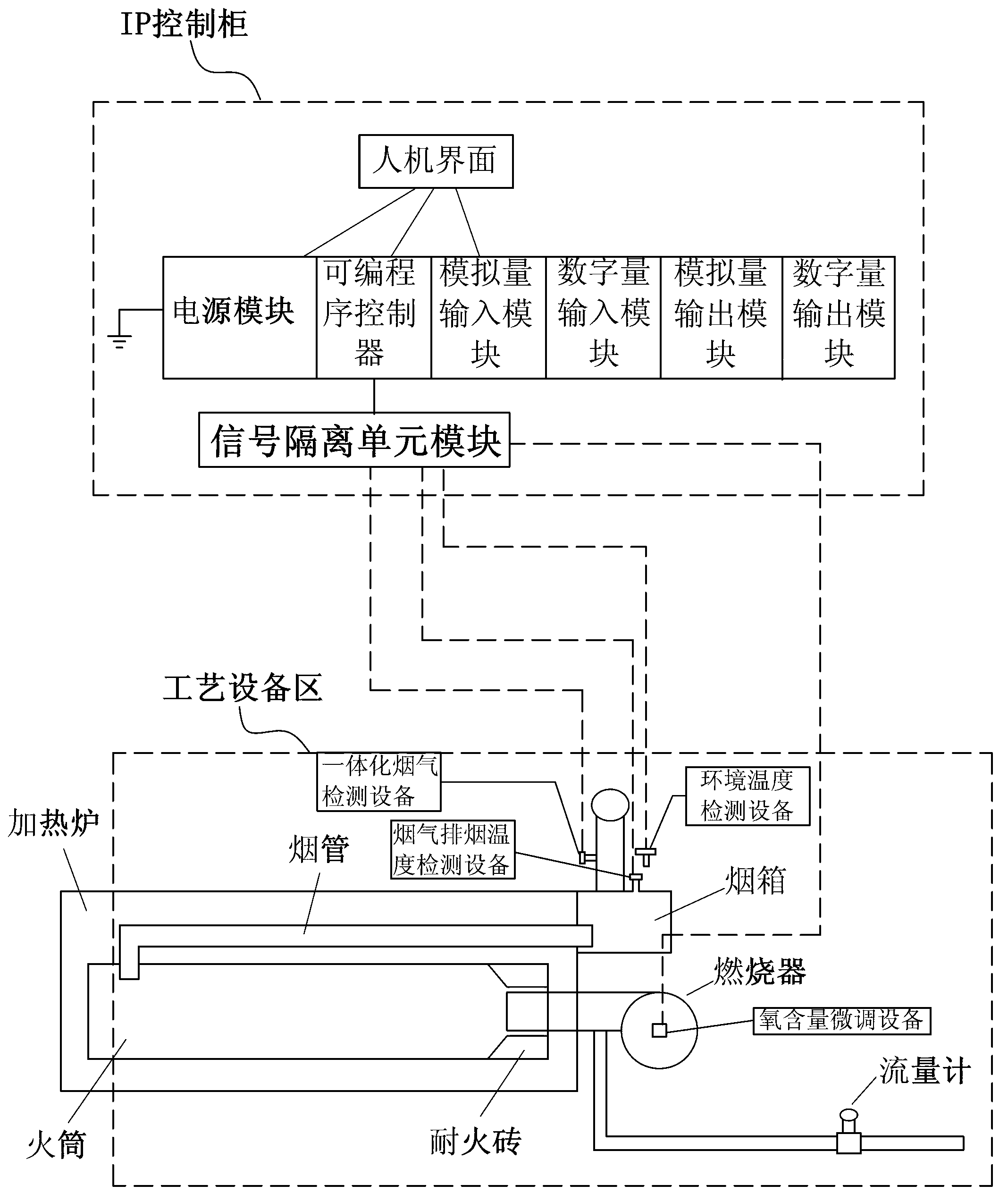

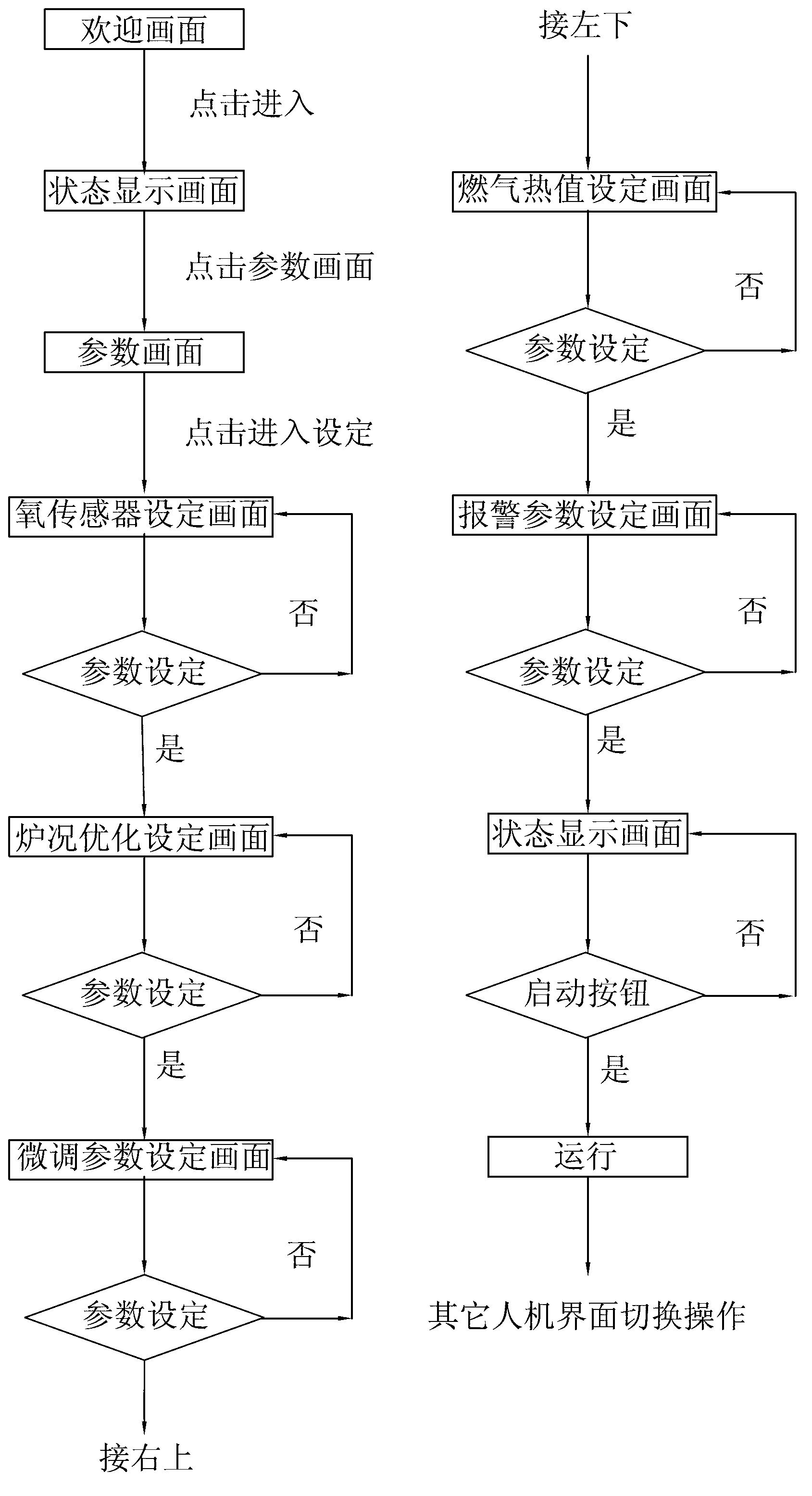

The invention discloses a furnace condition optimizing and monitoring device which improves operational conditions of a heating furnace or a boiler, improves efficiency and reduces energy consumption. A combustion device optimizing unit which is mainly an oxygen content fine adjustment device and is controlled by an automatic control unit is further arranged on an air inlet of a combustor, and the fine adjustment device comprises a control circuit with an optimization command receiving microprocessor. The furnace condition optimizing and monitoring device further comprises a curve memory comparison unit and a security and protection failure warning unit which carries out warning reminding on monitoring the project that the content of oxygen in exhausted smoke of the heating furnace is too high, and the like. According to the furnace condition optimizing and monitoring device, a security and protection effect-improving device which is matched in an integrated mode is adopted, a device monitoring and control system which integrates furnace condition overall optimization, safe production monitoring, machine pump system effect improving, automatic adjustment and operation, energy saving and consumption reduction as a whole is also adopted, the furnace effect of a heating furnace or a boiler matched with the furnace condition optimizing and monitoring device is improved, emission of oxygen content of smoke gas of the heating furnace or the boiler is reduced, smoke exhaust temperature and energy consumption of the heating furnace or the boiler are reduced, and therefore effective work of operation of a machine pump of the heating furnace or the boiler is enlarged, operation efficiency of the heating furnace or the machine pump of the boiler is improved, and the service life of the heating furnace or the machine pump of the boiler is prolonged.

Description

technical field [0001] The present invention relates to an oil field industrial heating furnace or other industrial boilers, in particular to an automatic furnace condition optimization monitoring device and an optimization method for improving the operating conditions of the heating furnace or boiler. technical background [0002] At present, industrial heating furnaces used in oil fields or boilers used in other industries are major consumers of industrial energy. Due to the lack of real-time security control means, the overall furnace operation status of the heating furnace lacks safety monitoring and optimization measures, making the commonly used heating furnaces or boilers The efficiency is generally low, the heating speed of the equipment is slow, the useless work of the pump operation is large, the system operation efficiency is low, and the oxygen content of the flue gas is excessively discharged, resulting in serious energy consumption and low production efficiency....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F24H9/20F22B35/00

Inventor 刘永才

Owner SHENZHEN JIAYUNTONG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com