Ultralow-energy-consumption smoke combustion type waste incineration method

A technology of waste incineration and energy consumption, which is applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of unsatisfactory water mist purification effect, unsatisfactory smoke and dust removal effect, and smoke and dust purification can not meet environmental protection requirements. Simple, improve the efficiency of the furnace, and thoroughly purify the smoke and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described below in conjunction with accompanying drawing:

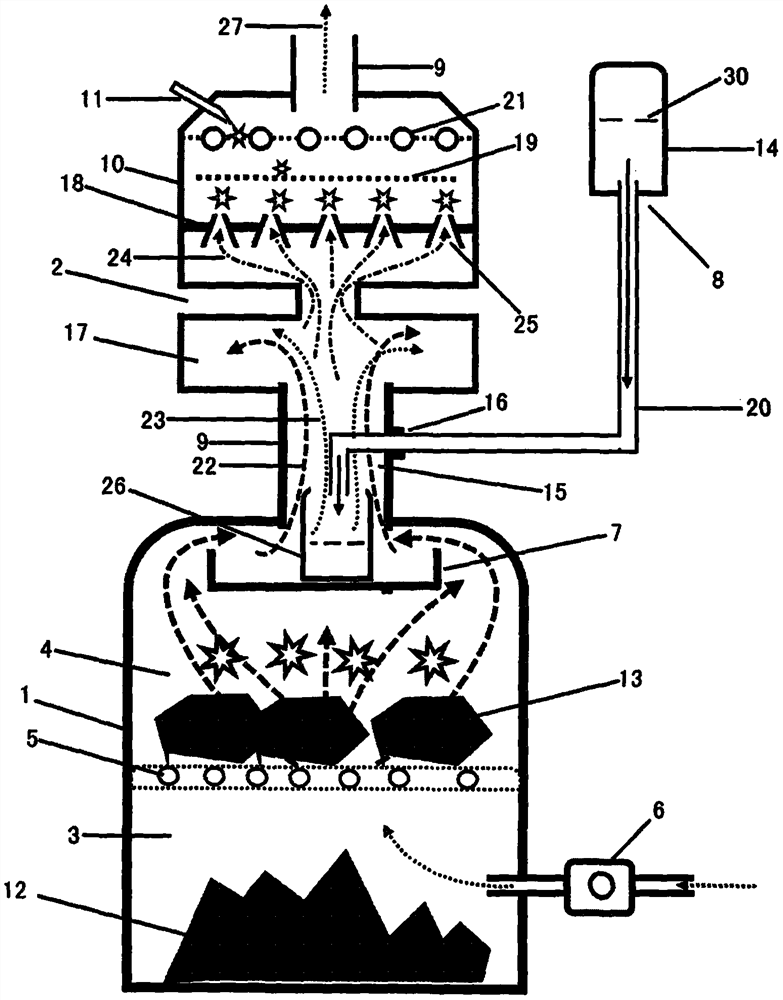

[0016] figure 1 Among them, the clean fuel vaporization supply device 15 is that there is a clean liquid fuel 30 in the external clean liquid fuel bottle 14, and the clean liquid fuel 30 enters the smoke pipe 9 from the clean fuel inlet 16 through the delivery pipe 20, and the clean liquid fuel 30 drops into it. The fuel vaporization plate 26 arranged below, the fuel vaporization plate 26 vaporizes the clean liquid fuel 30 under high temperature into vaporized clean fuel 23, the vaporized clean fuel 23 runs upwards and enters the mixing chamber 17, and the vaporized clean fuel 23 and the soot 22 are mixed Combustible smoke 24 is fully mixed in the air chamber 17 and is ignited when it runs upwards. The clean liquid fuel 30 is mainly an alcohol-based fuel, such as a fuel mainly composed of methanol, ethanol, and butanol.

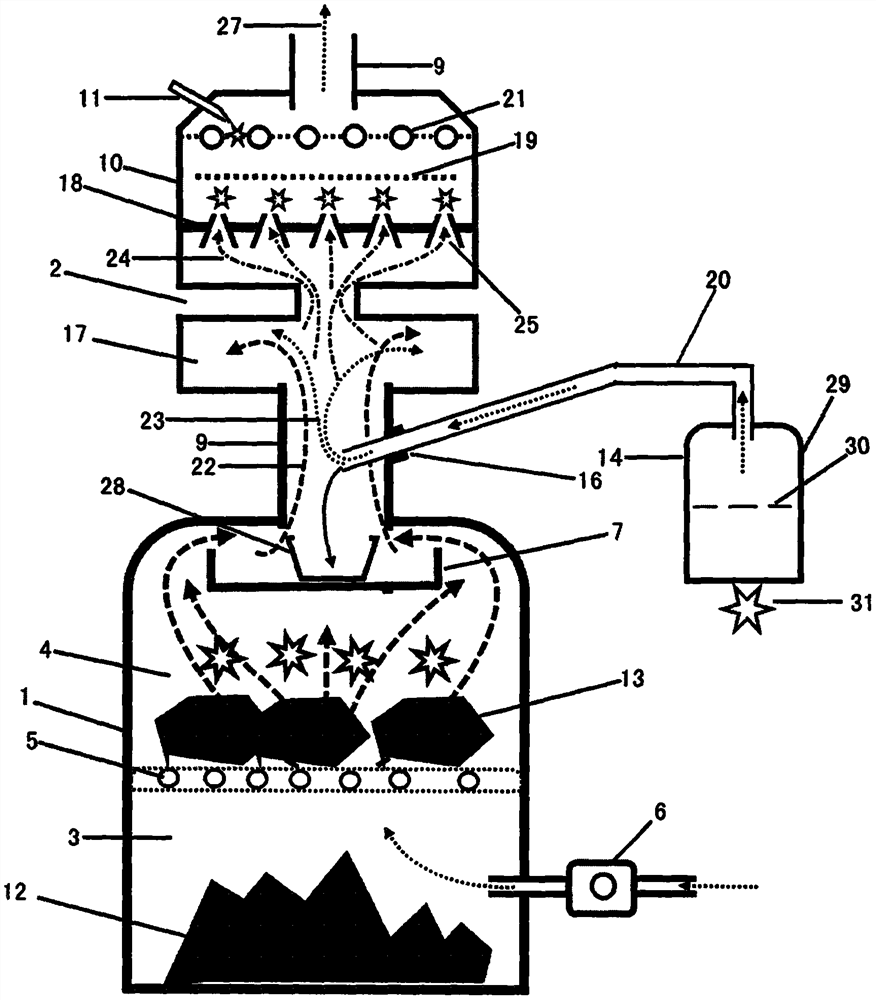

[0017] figure 2 Among them, the clean fuel vaporizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com