Thin film solar cell panel and preparation method of same

A technology of solar panels and solar cells, applied in circuits, photovoltaic power stations, photovoltaic power generation, etc., can solve the problem of not being able to directly process bendable solar cells, thin-film solar cells have not been well developed, and the degree of adaptability of different products Limitations and other issues, to achieve the effect of good insulation performance, good appearance, and improved light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below in conjunction with the specific embodiments shown in the accompanying drawings, but these embodiments do not limit the present invention, those of ordinary skill in the art make structural, method, or functional changes based on these embodiments All are included in the scope of protection of the present invention.

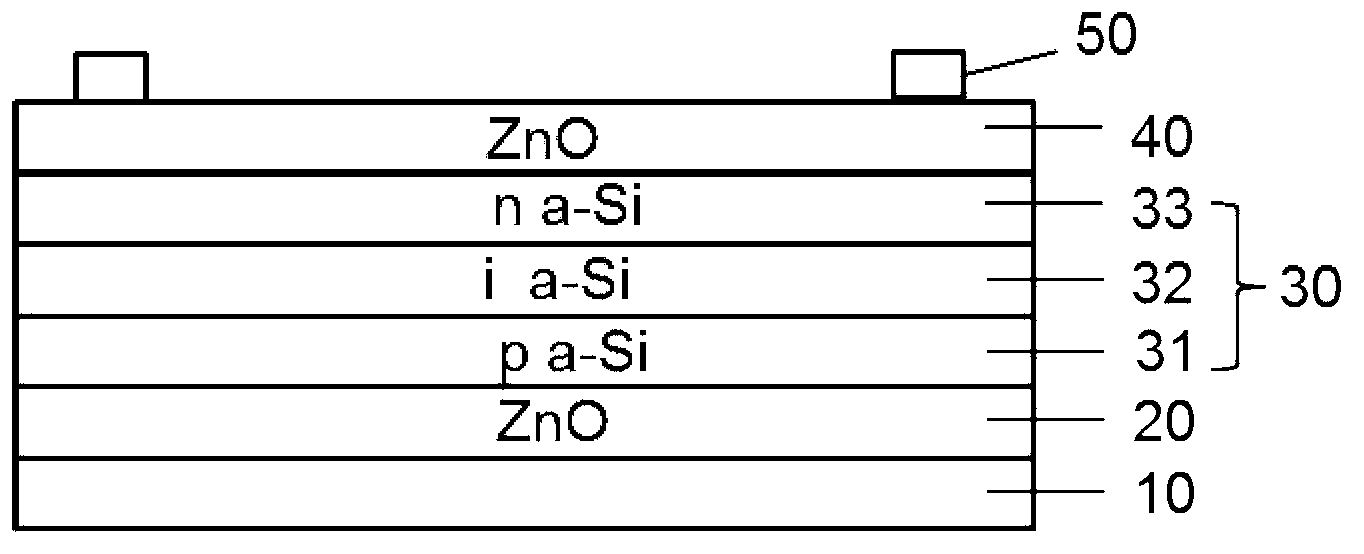

[0052] figure 1 It is a schematic diagram of a preferred embodiment of the thin film solar cell panel provided by the present invention. refer to figure 1 , the thin film solar cell panel includes a substrate 10, a first electrode 20 on the substrate, a photoelectric conversion layer 30 on the first electrode, a second electrode 40 on the photoelectric conversion layer 30, and Including the gate electrode 50 on the second electrode. The substrate 10 is an ultra-thin glass substrate, and the thickness of the ultra-thin glass substrate is 0.1-1mm. The ultra-thin glass substrate is bendable, and its m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com