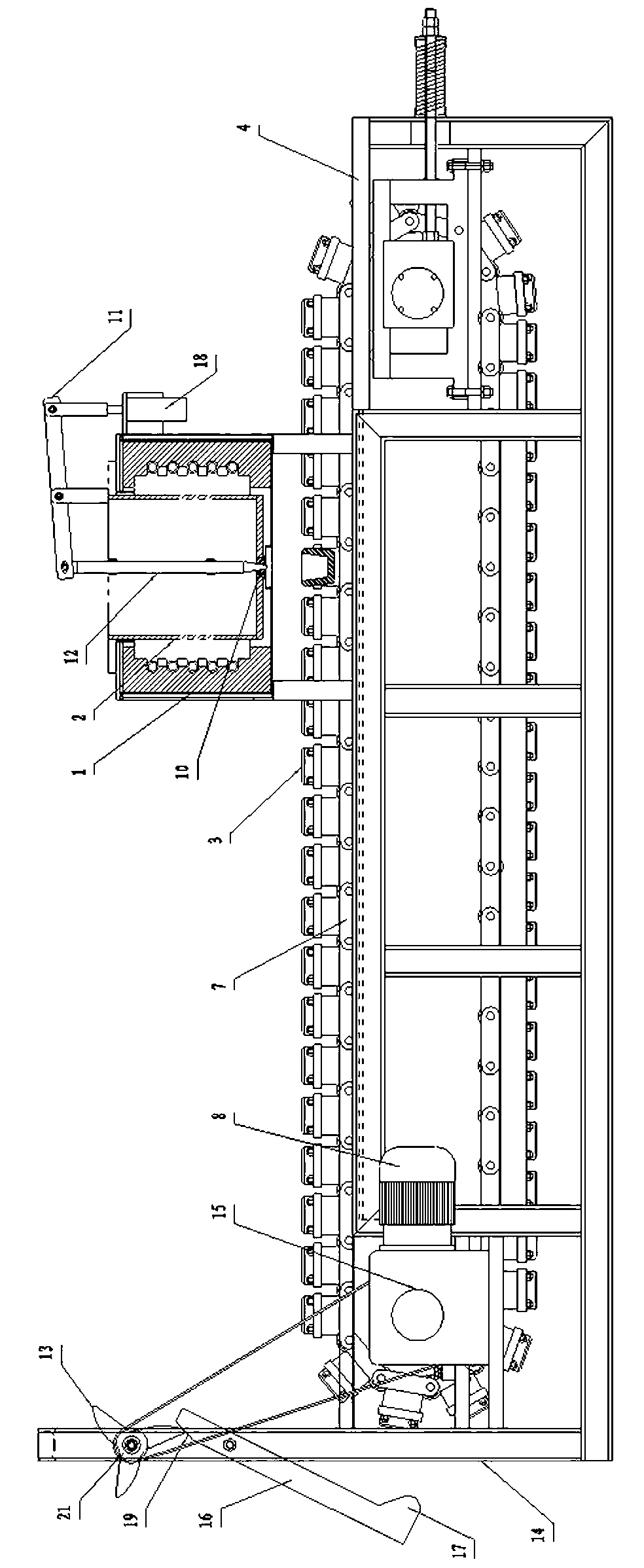

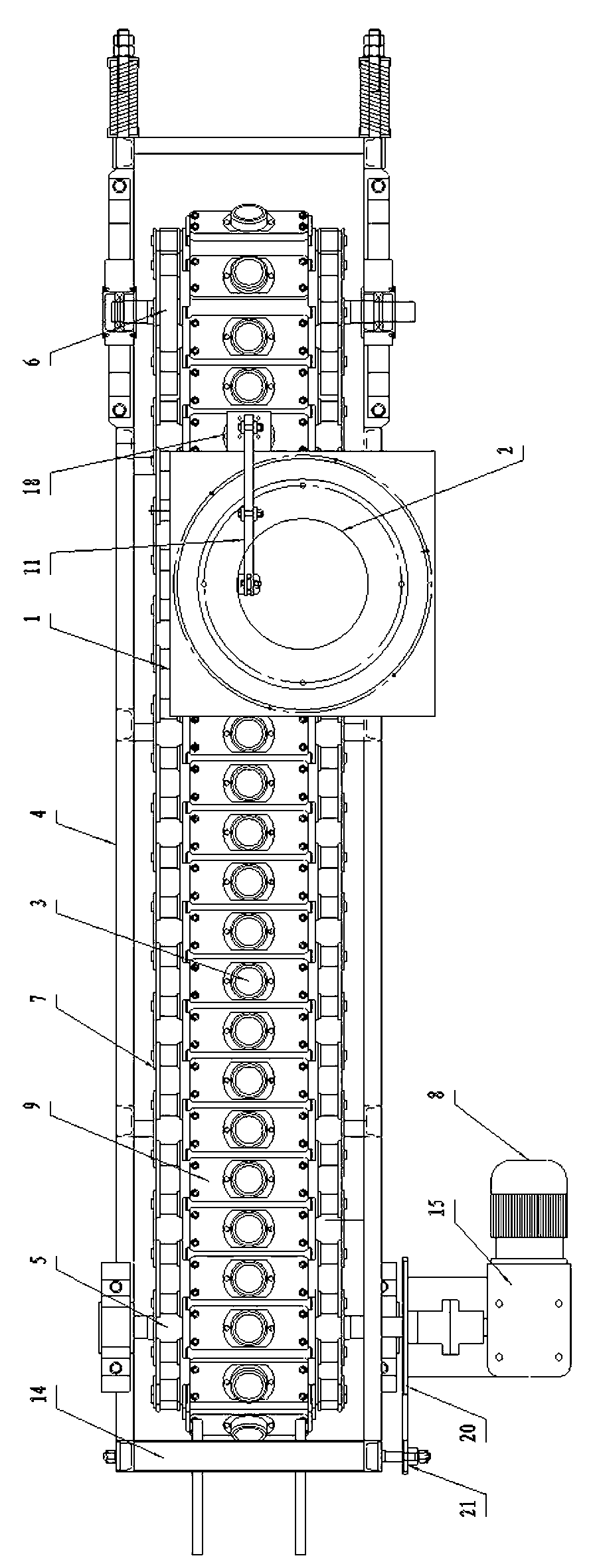

Small-size magnesium ingot casting machine

A casting machine and magnesium ingot technology, which is applied in foundry workshops, casting equipment, ingot workshops, etc., can solve the problems of no casting machine suitable for casting magnesium ingots, and achieve the effects of enhancing enterprise competitiveness, stable quality, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The small-sized magnesium ingot casting machine includes a holding furnace 1, a holding pot 2 set in the holding furnace 1 and containing molten magnesium, a number of molds 3, a frame 4, and a horizontal conveying mechanism arranged on the frame 4, connected to One end of the swing arm of the lever 11 and a driving mechanism that drives the other end of the swing arm of the lever 11 to reciprocate up and down. The horizontal conveying mechanism includes two driving sprockets 5 and two driven sprockets 6 respectively arranged at the front end and the rear end of the frame 4. , two conveyor chains 7, a motor 8, a reducer 15 connected to the motor 8, the reducer 15 is connected to the sprocket shaft of the driving sprocket 5 through a coupling, and a large sprocket is installed on the sprocket shaft of the driving sprocket 5 20. The two conveying chains 7 are respectively meshed with the sprockets on the corresponding sides of the two driving sprockets 5 and the two driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com