Fire-retardant warm-mixed asphalt additive

A warm-mix asphalt and additive technology, applied in the field of road asphalt materials, can solve the problems of unfavorable quality control by manual feeding, cumbersome metering and sub-packaging process, and small single additive dosage, and achieve low production cost, good high temperature stability and Water damage resistance, the effect of a simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

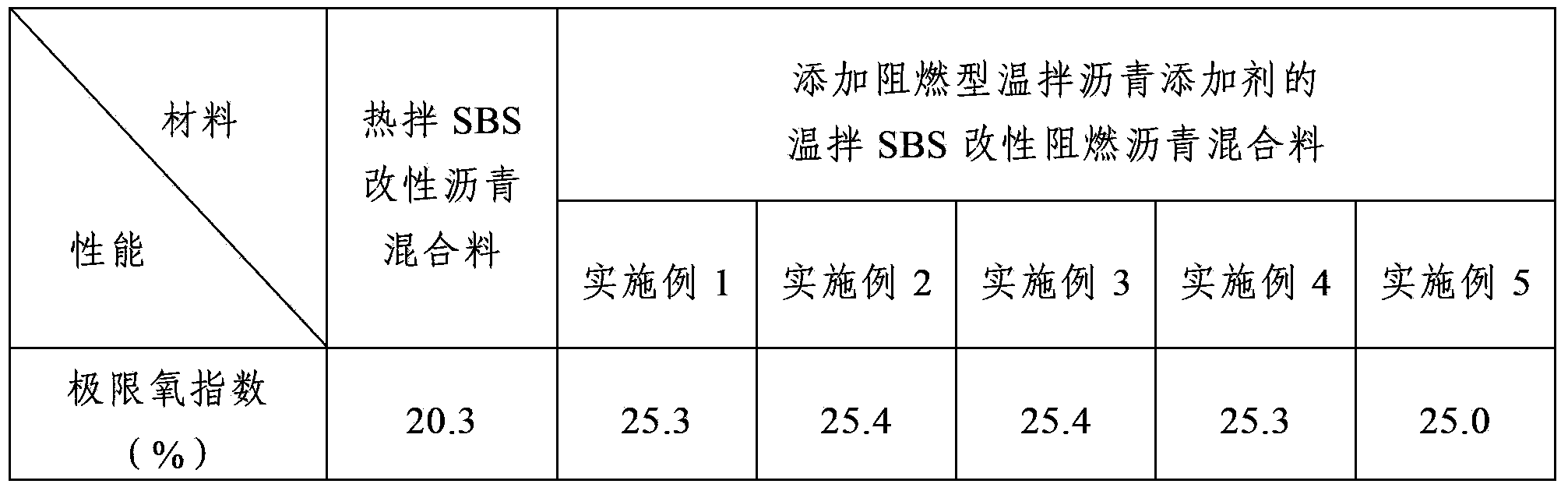

Embodiment 1

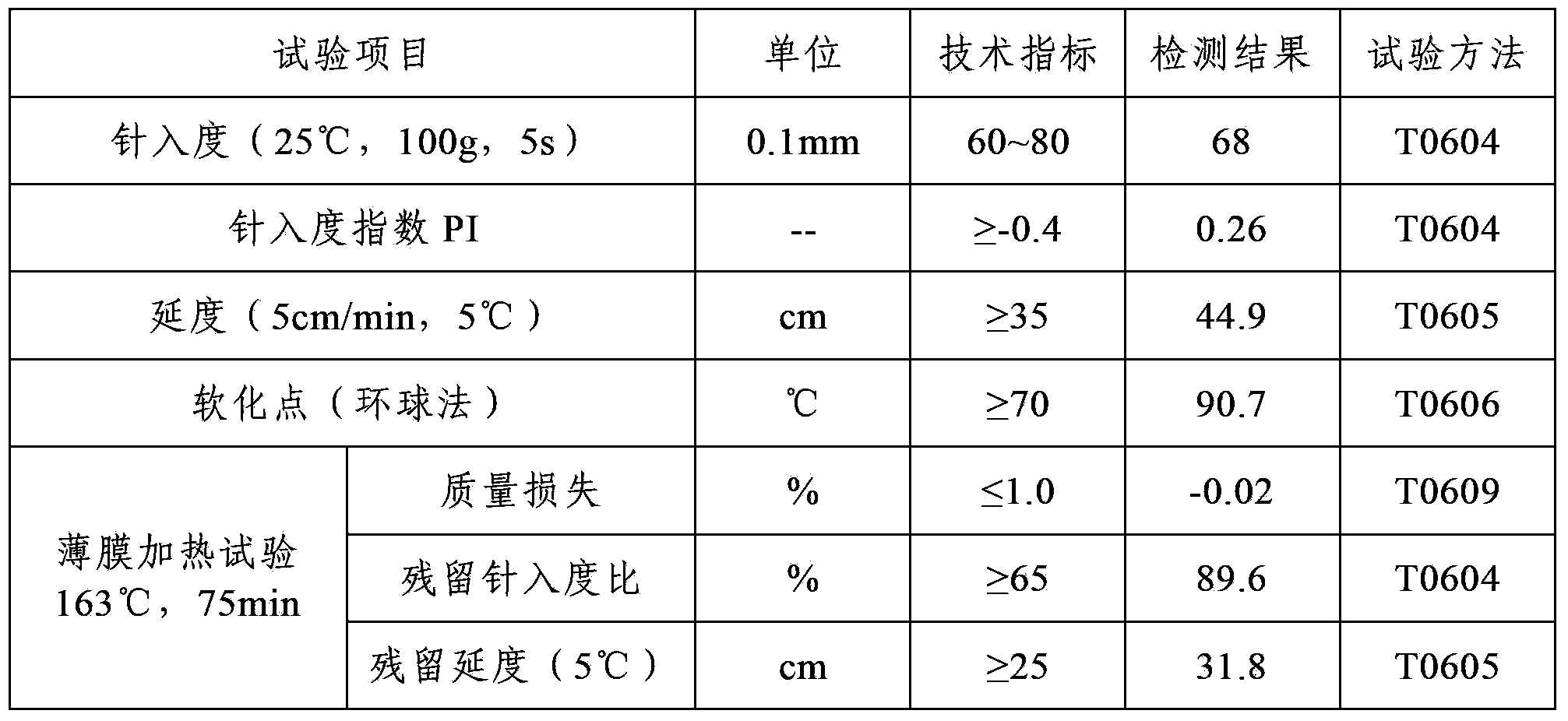

[0019] The flame retardant warm mix asphalt additive in this example is made by mixing and ball milling the following raw materials in parts by weight: 23 parts of sodium aluminosilicate, 21 parts of ammonium polyphosphate, 6 parts of melamine, 2 parts of pentaerythritol, 14 parts of diatomaceous earth, dry powder interface 0.4 parts of agent; preferably, the dry powder interface agent is redispersible latex powder, the speed of the ball milling is 400r / min, and the time of the ball milling is 36min.

Embodiment 2

[0021] The flame-retardant warm-mix asphalt additive in this example is made by mixing and ball-milling the following raw materials in parts by weight: 24 parts of sodium aluminosilicate, 22 parts of ammonium polyphosphate, 5 parts of melamine, 3 parts of pentaerythritol, 15 parts of diatomaceous earth, dry powder interface 0.5 parts of agent; preferably, the dry powder interface agent is redispersible latex powder, the speed of the ball milling is 350r / min, and the time of the ball milling is 43min.

Embodiment 3

[0023] The flame retardant warm mix asphalt additive in this example is made by mixing and ball milling the following raw materials in parts by weight: 26 parts of sodium aluminosilicate, 23 parts of ammonium polyphosphate, 8 parts of melamine, 4 parts of pentaerythritol, 16 parts of diatomaceous earth, dry powder interface 0.6 part of agent; preferably, the dry powder interface agent is redispersible latex powder, the speed of the ball milling is 500r / min, and the time of the ball milling is 30min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com