Method for preparing flame-retardant rubber modified emulsified asphalt

A technology of emulsified asphalt and flame-retardant rubber, which is applied in building components, building insulation materials, buildings, etc., can solve problems such as limited thickness, and achieve the effect of accelerating promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

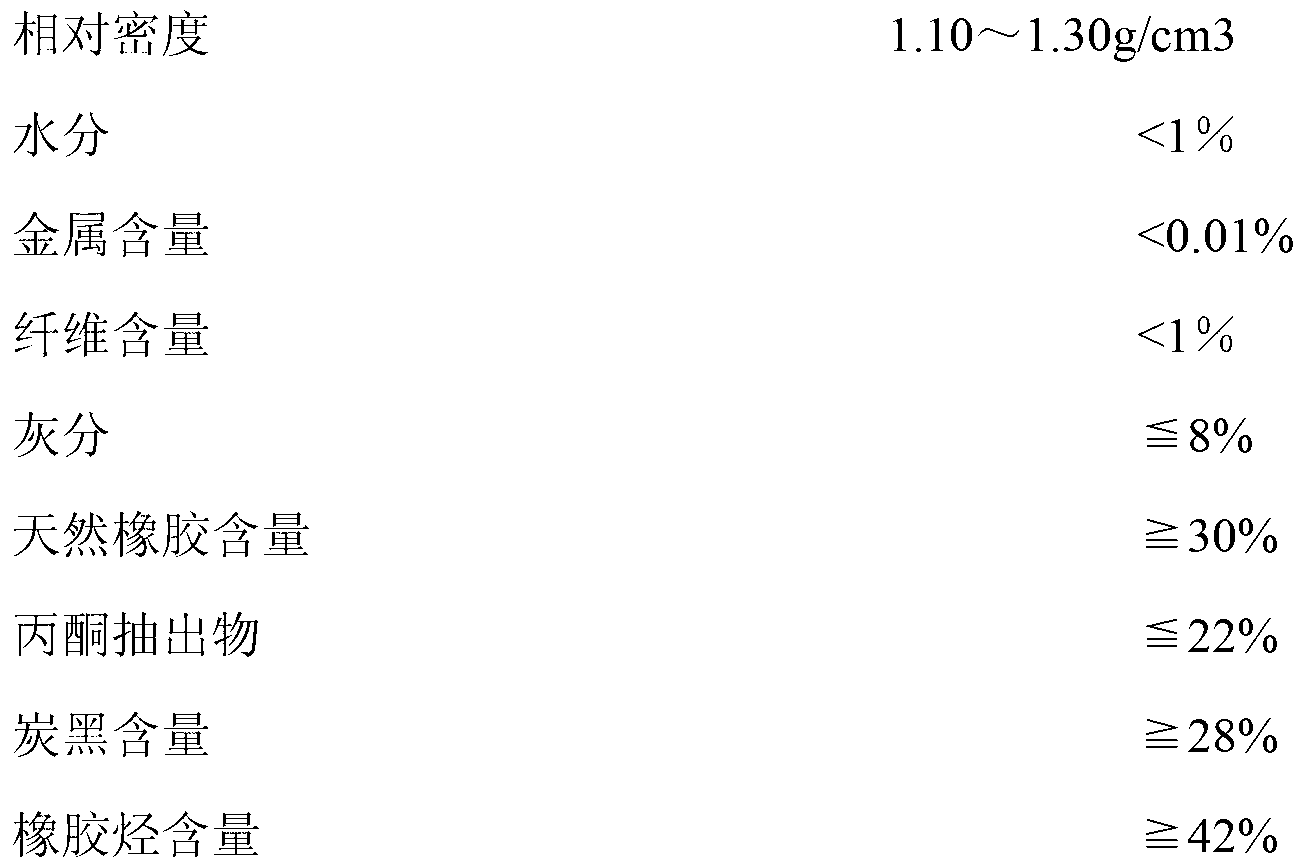

[0069] Example 1: Preparation of flame-retardant modified emulsified asphalt with a solid content of 65.1%

[0070] The flame-retardant modified emulsified asphalt preparation of the present invention is all calculated as 100 parts according to the total weight of base asphalt:

[0071]

[0072]

[0073] Example 1 preparation method is:

[0074] Heat base asphalt to 130-140°C, inject emulsifier into water at 60-70°C, stir for 1-2 minutes to form emulsion (or called emulsion, soap liquid); then inject organic flame retardant into the stirred emulsion , and continue to stir for 1-2 minutes to become a flame-retardant emulsion containing a certain proportion of emulsifier and organic flame retardant; and then inject the flame-retardant emulsion into the colloid mill, which will account for 80% of the total mass of the required base asphalt, 130 The base asphalt at ~140°C is injected into the colloid mill and the emulsion is sheared and emulsified together. After 1-2 minute...

example 2

[0082] Example 2: Preparation of flame-retardant modified emulsified asphalt with a solid content of 62.2%

[0083] The flame-retardant modified emulsified asphalt preparation of the present invention is calculated according to the total weight of base asphalt being 100 parts:

[0084] Base bitumen 100 parts

[0085] Flame retardant 12 parts

[0086] Compound method of the present invention can adopt following several steps:

[0087] (1) Preparation of rubber powder modified asphalt: first heat the base asphalt in the rubber asphalt reactor to 180-195°C, then screw the rubber powder that meets the design requirements and put it into the reactor, perform mechanical stirring, and develop, Swell for 45min.

[0088] (2) Preparation of emulsion: inject the emulsifier into water at 60-70°C, stir for 1-2 minutes to form an emulsion (or called emulsion, soap liquid); then inject the organic flame retardant into the stirred emulsion, and After continuing to stir for 1-2 minutes, it...

example 3

[0126] Example 3: Preparation of flame retardant modified emulsified asphalt with a solid content of 58.0%

[0127] The flame retardant rubber modified emulsified bitumen preparation of the present invention all calculates as follows according to the total weight of base bitumen being 100 parts:

[0128]

[0129] First, the base asphalt in the rubber asphalt reactor is heated to 180-195°C, and then the rubber powder that meets the design requirements is screwed into the reactor, stirred mechanically, and developed and swelled for 45 minutes. Next, inject the emulsifier into water at 60-70°C, stir for 1-2 minutes to form an emulsion (or called emulsion, soap liquid); then inject the organic flame retardant into the stirred emulsion, and continue stirring for 1-2 minutes. After 2 minutes, it becomes a flame retardant emulsion containing a certain proportion of emulsifier and organic flame retardant; finally, after the flame retardant emulsion is injected into the colloid mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com