High-toughness powder coating specially used for security door

A powder coating, high toughness technology, applied in powder coating, polyester coating, coating, etc., can solve the problems that cannot meet the requirements of anti-theft doors, such as coating first and then molding, to achieve the effect of improving toughness and optimizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

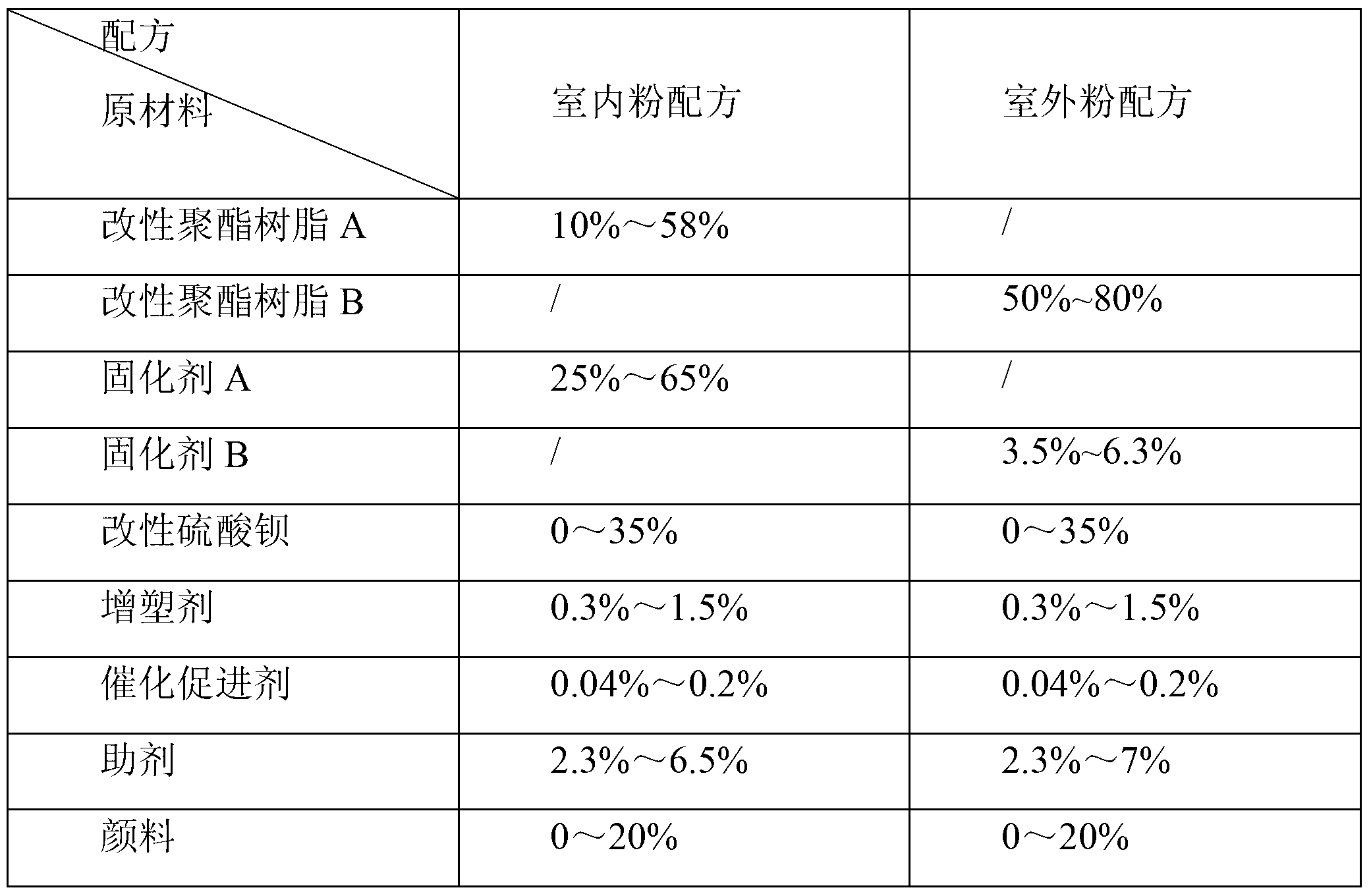

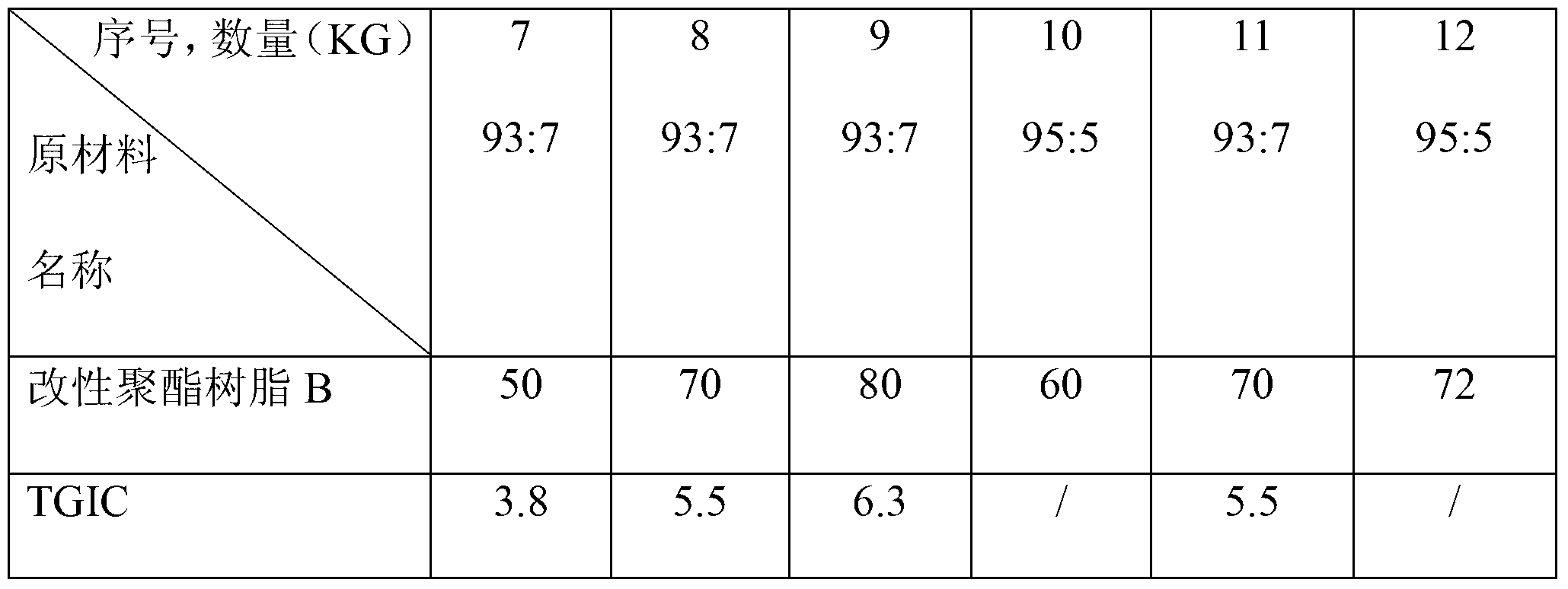

[0030] Table 2 Example formula of indoor powder coating

[0031]

[0032] In Table 2, 50:50, 60:40 and 70:30 represent the effective reaction ratios of modified polyester resin A and epoxy resin.

[0033] Accurately weigh the materials according to the formula in Table 2, and place them in a high-speed mixer to mix for 5 minutes; the mixed materials are extruded with an extruder at a temperature of 90 °C in zone 1 and 115 °C in zone 2; the extruded materials are pulverized with an ACM pulverizer A 180-mesh sieve is used to prepare a powder product with a D50 particle size of 28-37 microns for later use.

[0034] The tough coating produced by the above production process is sprayed on a steel plate with a thickness of 0.4 to 2.0 mm using 60-90KV high-voltage static electricity, with an average coating thickness of 50-90 microns; curing conditions are: workpiece temperature 170-190 ℃, baking 10 to 20 minutes.

[0035] Table 2 Examples 1, 2, 3, and 4 are high-gloss powder co...

Embodiment 7~12

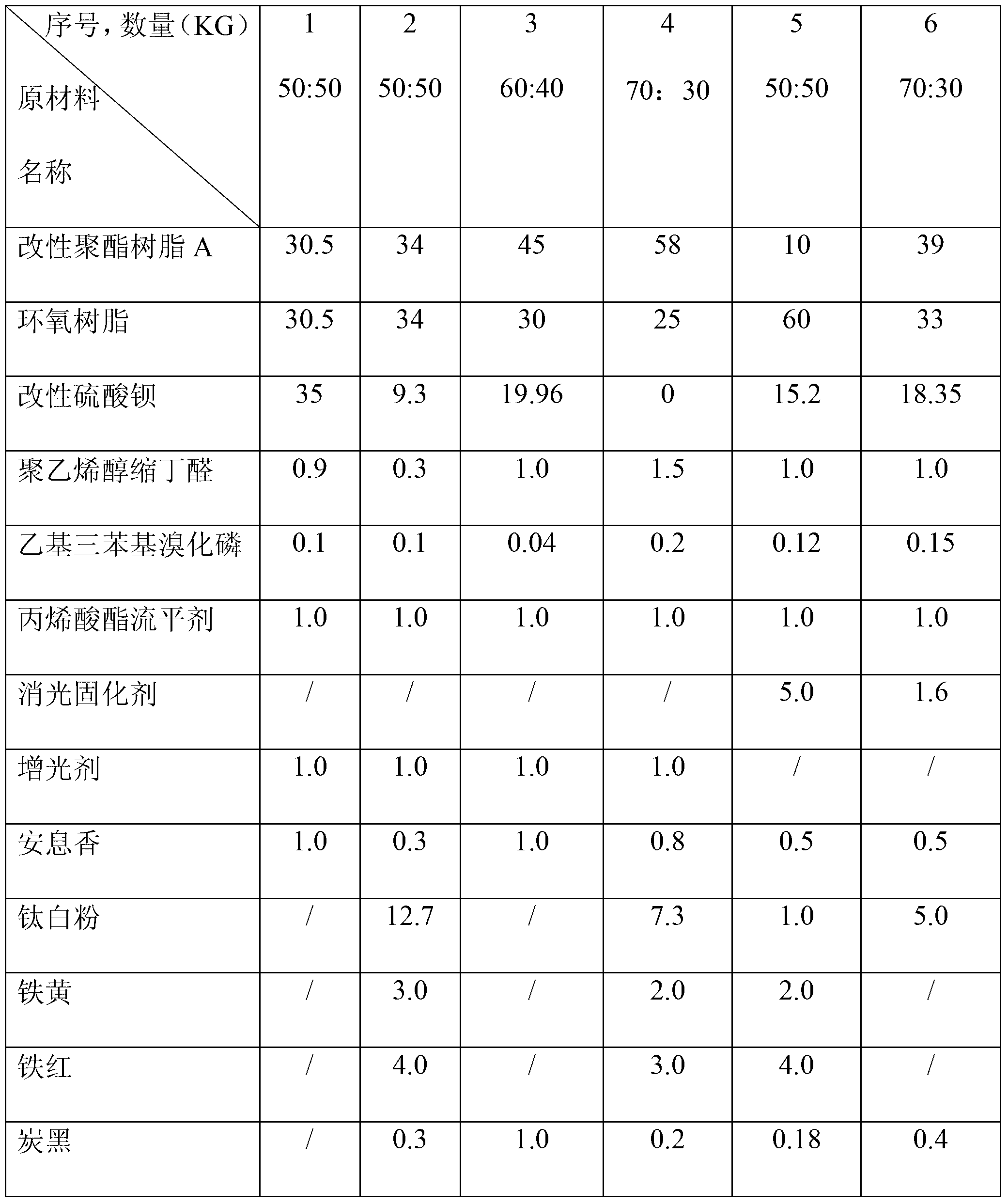

[0039] Table 4 Formulations of 7-12 Examples of Outdoor Powder Coatings

[0040]

[0041]

[0042] Accurately weigh the materials according to the formula in Table 4, and place them in a high-speed mixer to mix for 5 minutes; the mixed materials are extruded with an extruder at a temperature of 90 °C in zone 1 and 115 °C in zone 2; the extruded materials are pulverized with an ACM pulverizer A 180-mesh sieve is used to prepare a powder product with a D50 particle size of 28-37 microns for later use.

[0043] The tough coating produced by the above production process is sprayed on a steel plate with a thickness of 0.4 to 2.0 mm using 60-90KV high-voltage electrostatic, with an average coating thickness of 50-90 microns; curing conditions are: workpiece temperature 180-200 ° C, baking 10 to 20 minutes.

[0044] Table 4 Examples 7, 8, 9, and 10 are high-gloss powder coatings, wherein the modified barium sulfate is modified precipitated barium sulfate, and Examples 11 and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap