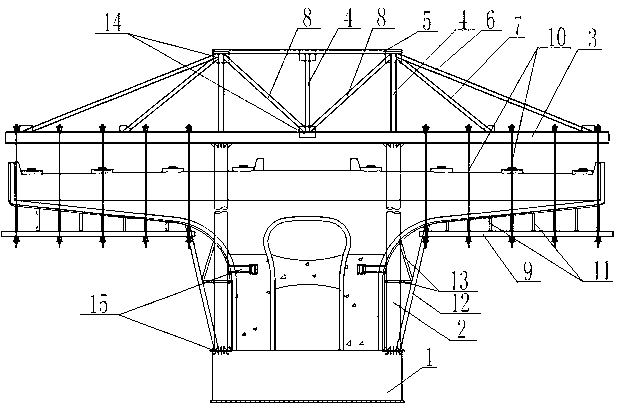

Steel truss cantilever support and implementation method thereof

A realization method and technology of steel truss, applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., can solve the problems of large floor space and cannot meet the needs of traffic flow, etc., and achieve the effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Such as figure 1As shown, this embodiment is used in the Chengwen Road Reconstruction Project in the Chengdu Second Ring Road Reconstruction Project to slow congestion and maintain smoothness in the central urban area. Wen Road), the project starts from the Chengwen Overpass on the Second Ring Road in the east, passes through South Shuangqing Road, Jinsha Station, Qingyang Avenue, West Qingjiang Road in the west, and ends at the east side of the Supo Overpass on the Third Ring Road in the west, with a total length of about 2.1 kilometers , the construction mileage is K1+705-K1+920 (that is, the main pier 43#-48#), located in the center of the original Chengwen Road, crossing Qingyang Avenue (2.5 Ring Road), Qingjiang Middle Road Subway Station of Metro Line 4 (with the subway Line 7 transfer station) is located in this section; Qingjiang Middle Road Subway Station of Metro Line 4 (transfer station with Metro Line 7), the station length is 205.2m, the maximum width is 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com