Construction method of shear wall and column formwork for main structure

A main structure and shear wall technology, applied in building construction, building material processing, construction, etc., can solve the problems of prolonged construction period and difficult control of concrete quality, shortening construction period, saving construction period and human resources, shortening The effect of construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

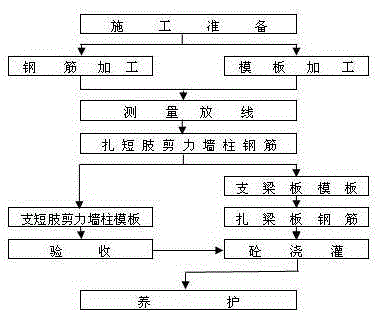

[0029] The construction method of the short-leg shear wall and column formwork construction technology in the main structure after the beam slab, taking the construction technology of the main structure of the 2# building in a certain garden in Wuxue, Hubei as an example, for the short-limb shear wall of the present invention, the column frame The various organizational links of the construction of the main structure of the shear system are comprehensively described. Construction process flow chart see figure 1 .

[0030] 1. Construction preparation steel bar processing

[0031] 1) Do a good job of site layout and site hardening.

[0032] 2) Pile up short-limb shear walls, columns, beams, and slab steel bars prepared on site according to specifications.

[0033] 2. Construction preparation formwork processing

[0034] 1) Selection of formwork materials for short-leg shear walls, columns and beams, and floor slabs:

[0035] a. In the short-limb shear wall and column-frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com