Large-drift-diameter packer used for oil well

A packer and large-diameter technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problem of rubber tubes prone to shoulders, unstable slip anchoring, complex mechanical structures, etc. problems, to achieve the effect of improving the sealing, anchoring and sealing actions are simple, coherent and easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

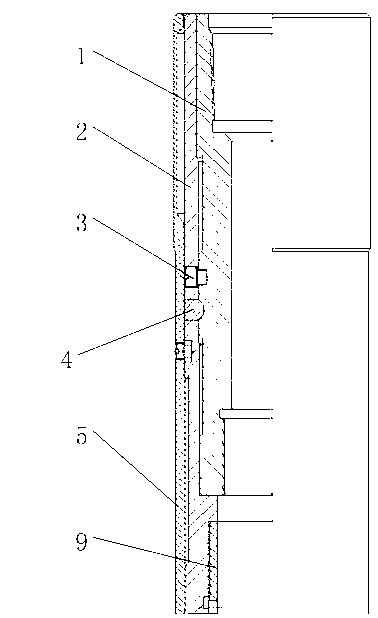

[0032] see figure 1 , a large-bore packer for oil wells, including a drop-off module 101 , a pack-off module 102 , an anchor module 103 and a lower joint module 104 . It is characterized in that: before the packer is set and anchored, the upper end of the drop-off module 101 is connected to the ground downhole device through pipe threads, and the lower end of the drop-off module 101 is connected to the lower joint through the isolation module 102 and the anchor module 103 in sequence. Modules 104 are connected in one piece.

Embodiment 2

[0034] see Figure 2~Figure 5 , the present embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0035] The hands-free module 101 includes a hands-free joint 1, a hands-free lock sleeve 2, a lock block 3 and a hands-free shear nail 4; the upper end of the hands-free joint 1 passes through 2 7 / 8The TBG pipe thread is connected with the surface downhole device, the locking sleeve 2 is covered with the locking joint 1, and is connected with the locking sleeve 2 in the middle through the locking block 3 and the locking shear nail 4, and the packer is set and sealed Continue to pressurize afterward, make the shear nail 4 be cut off, the lock sleeve 2 rises, the lock block 3 slides, the upper structure of the hand is proposed with the oil pipe, and the lower joint is connected with the central pipe 9.

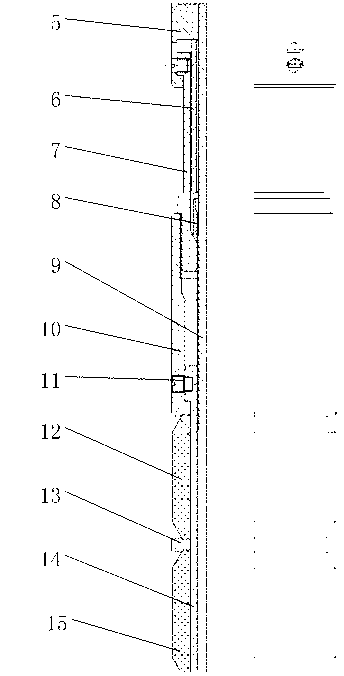

[0036] The isolation module 102 includes a liquid cylinder 5, an upper inner ferrule 6, a locking ring sleeve 7, an upper locking ring 8, ...

Embodiment 3

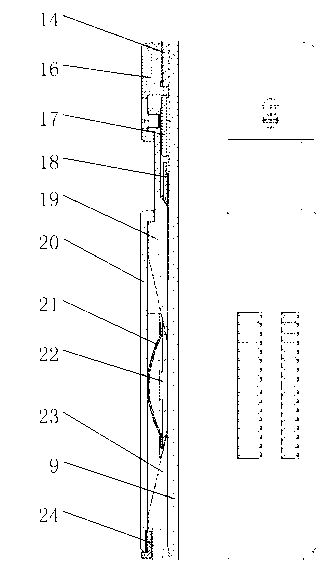

[0044] see Figure 1~Figure 5 , a large diameter packer used for oil wells, the main parts of the isolation module include hydraulic cylinder 5, upper inner ferrule 6, lock ring sleeve 7, upper lock ring 8, center pipe 9, rubber sleeve thrust sleeve 10, setting seal Shear nail 11, limiting rubber tube 12, rubber tube spacer ring 13, rubber tube sliding sleeve 14, working rubber tube 15; the main parts of the anchor module include rubber tube seat 16, lower inner ferrule 17, lower locking ring 18, upper vertebra Body 19, slip tube 20, leaf spring 21, slips 22, lower vertebral body 23, limit sleeve 24.

[0045] In this embodiment, the packer is used in conjunction with a hollow oil well pump. When working, the lower joint of the packer and the upper joint of the pump barrel are connected through a 3-inch flat tubing buckle, and the seal is reliable. Connect the isolation anchor device with the oil well pump on the ground, and after lowering the isolation anchor device and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com