High pressure fuel pump driving structure

A driving structure and fuel pump technology, applied in liquid fuel engines, pumps, pump components, etc., can solve the problems of reducing the noise reduction effect of helical gears, frequent axial movement, shortening life, etc. Simple installation and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

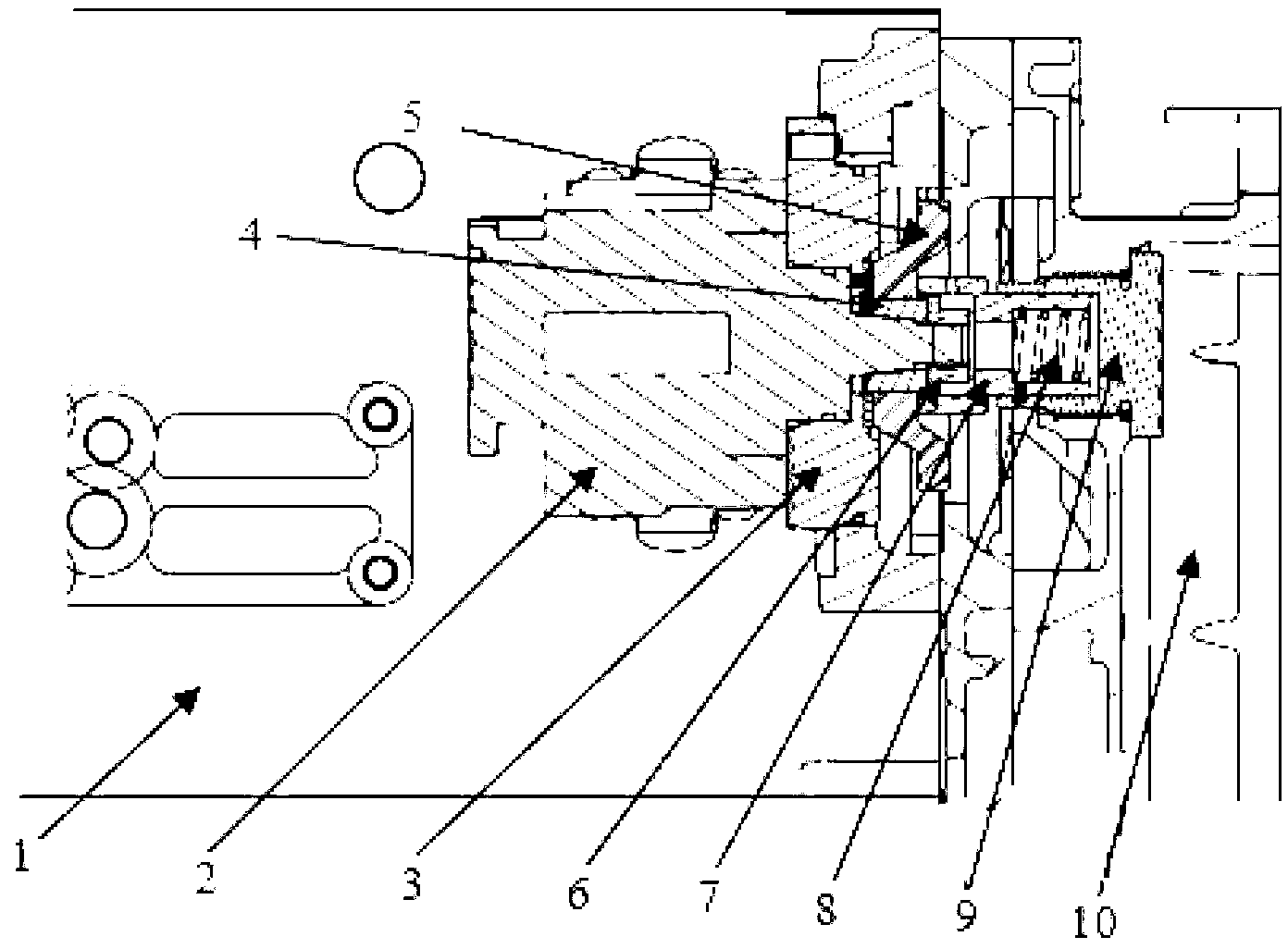

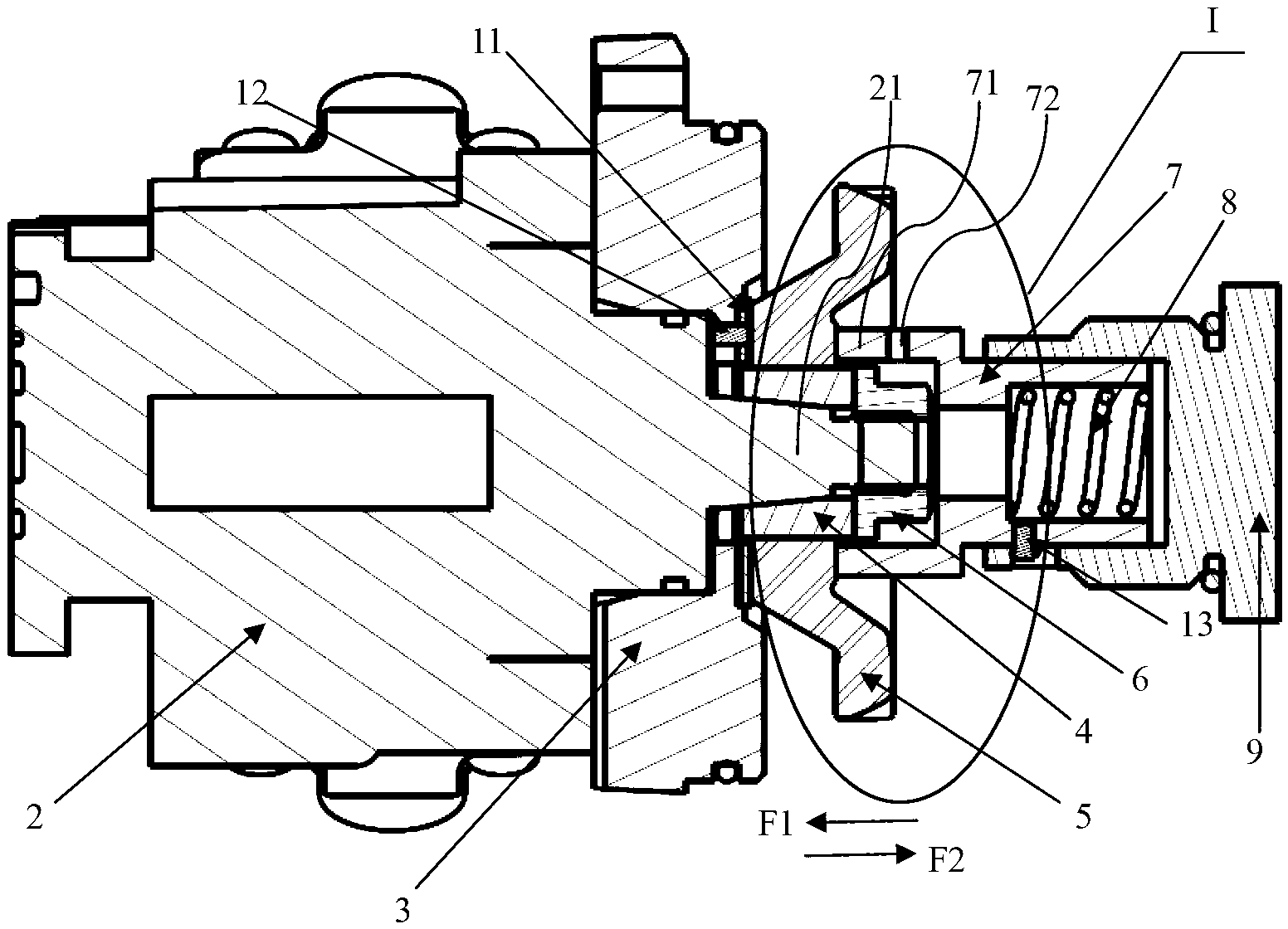

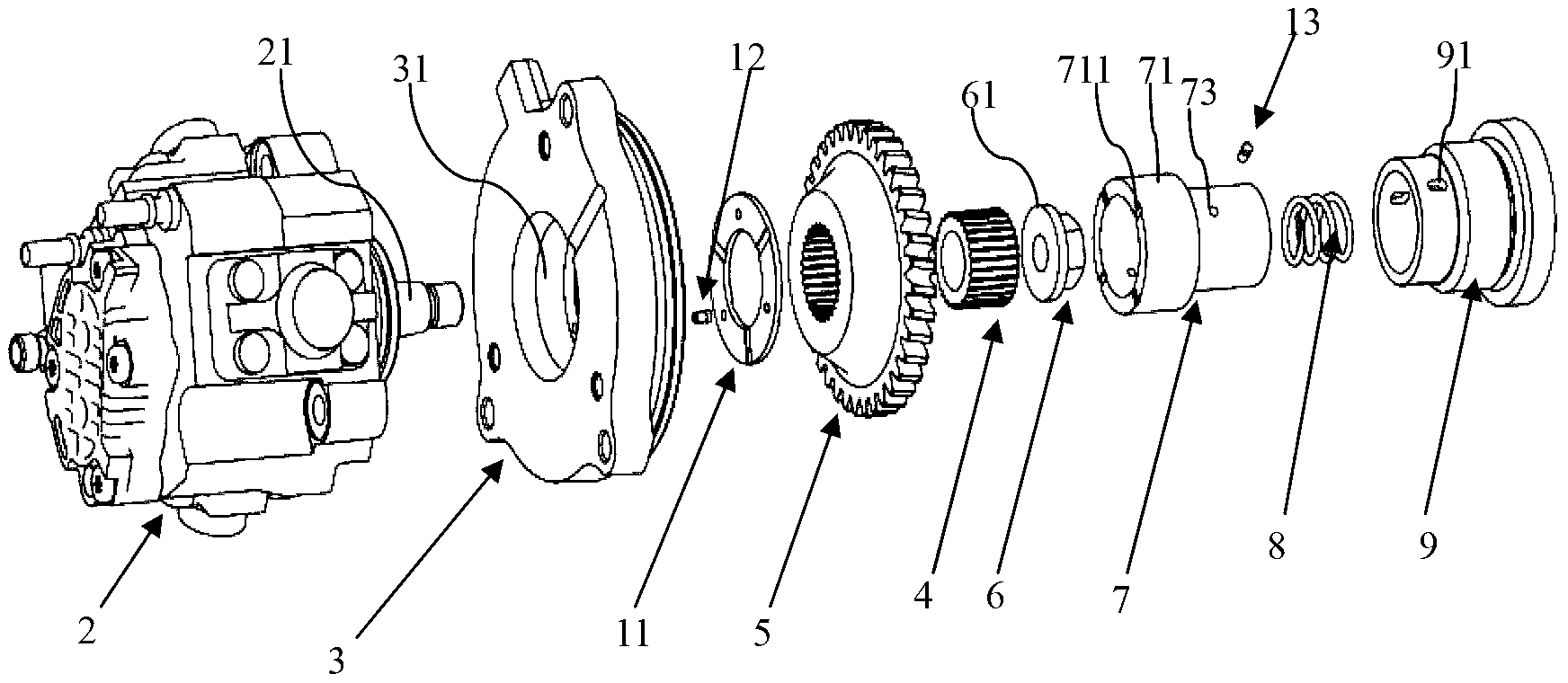

[0031] Next, specific embodiments of the present invention will be further described in detail with reference to the accompanying drawings.

[0032] to combine Figure 1 to Figure 3 , the high-pressure fuel pump 2 is installed on the cylinder 1 through the flange 3, the flange 3 has a shaft hole 31, the pump shaft 21 of the high-pressure fuel pump 2 passes through the shaft hole 31 and extends into the sprocket chamber of the engine (unmarked), The timing gear train is housed in the sprocket chamber. In the sprocket chamber, the casing 4 is set on the pump shaft 21 and fastened by the nut 6 to realize the fixed installation of the casing 4 and the pump shaft 21 . Those of ordinary skill in the art can easily imagine that the sleeve 4 can also be fitted on the pump shaft 21 through an interference fit, but from the perspective of easy disassembly and assembly, it is obviously more advantageous to use a nut. The sleeve 4 has external splines, the helical gear 5 has internal sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com