Device used for detecting defects of attached layers of iron-based sealing container

A closed container and adhesion layer technology, applied in electromagnetic measurement devices, electric/magnetic thickness measurement, etc., can solve the problems of damage, dangerous operation, low efficiency, etc., to improve detection efficiency, avoid high-altitude operations, and enhance reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

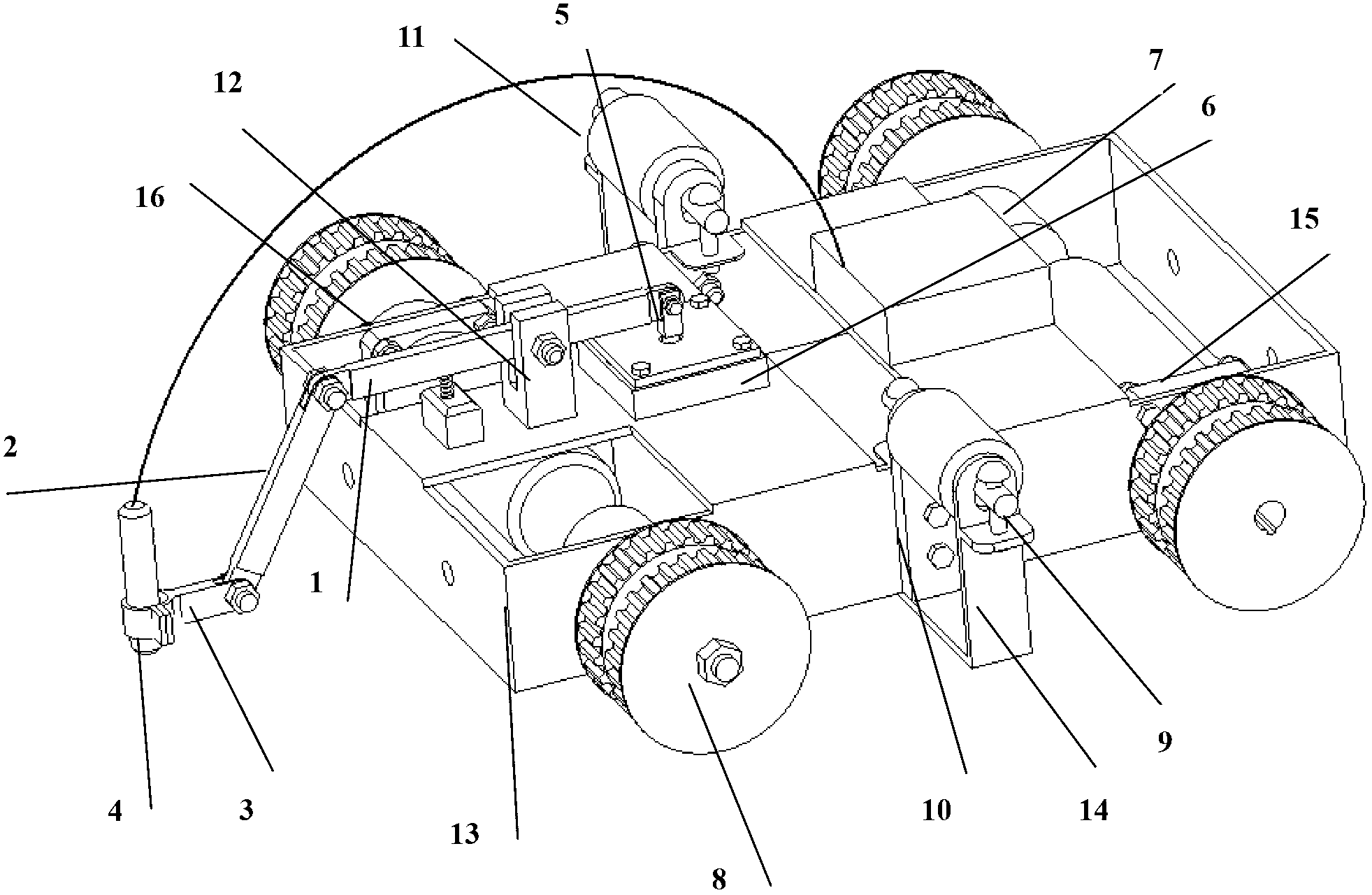

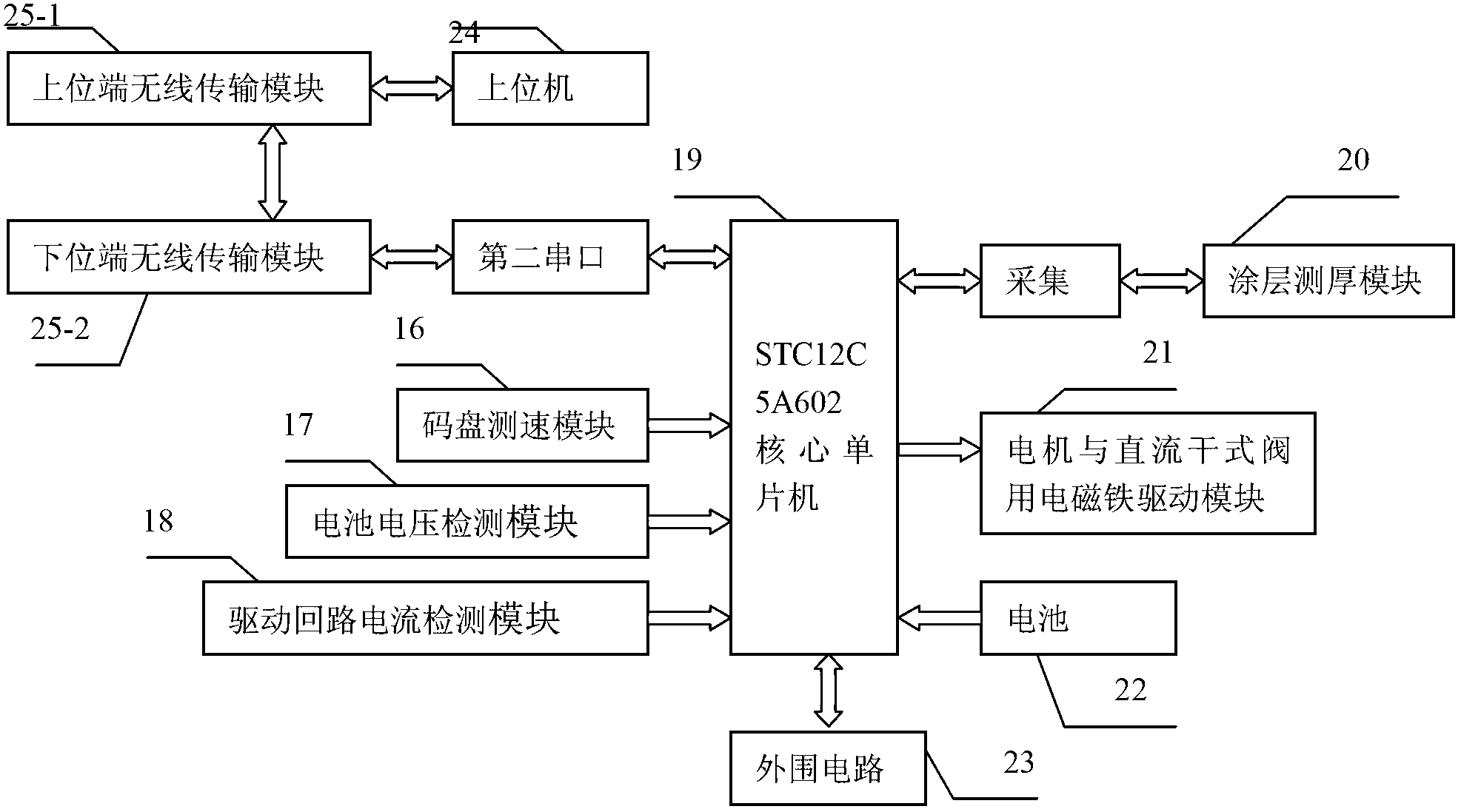

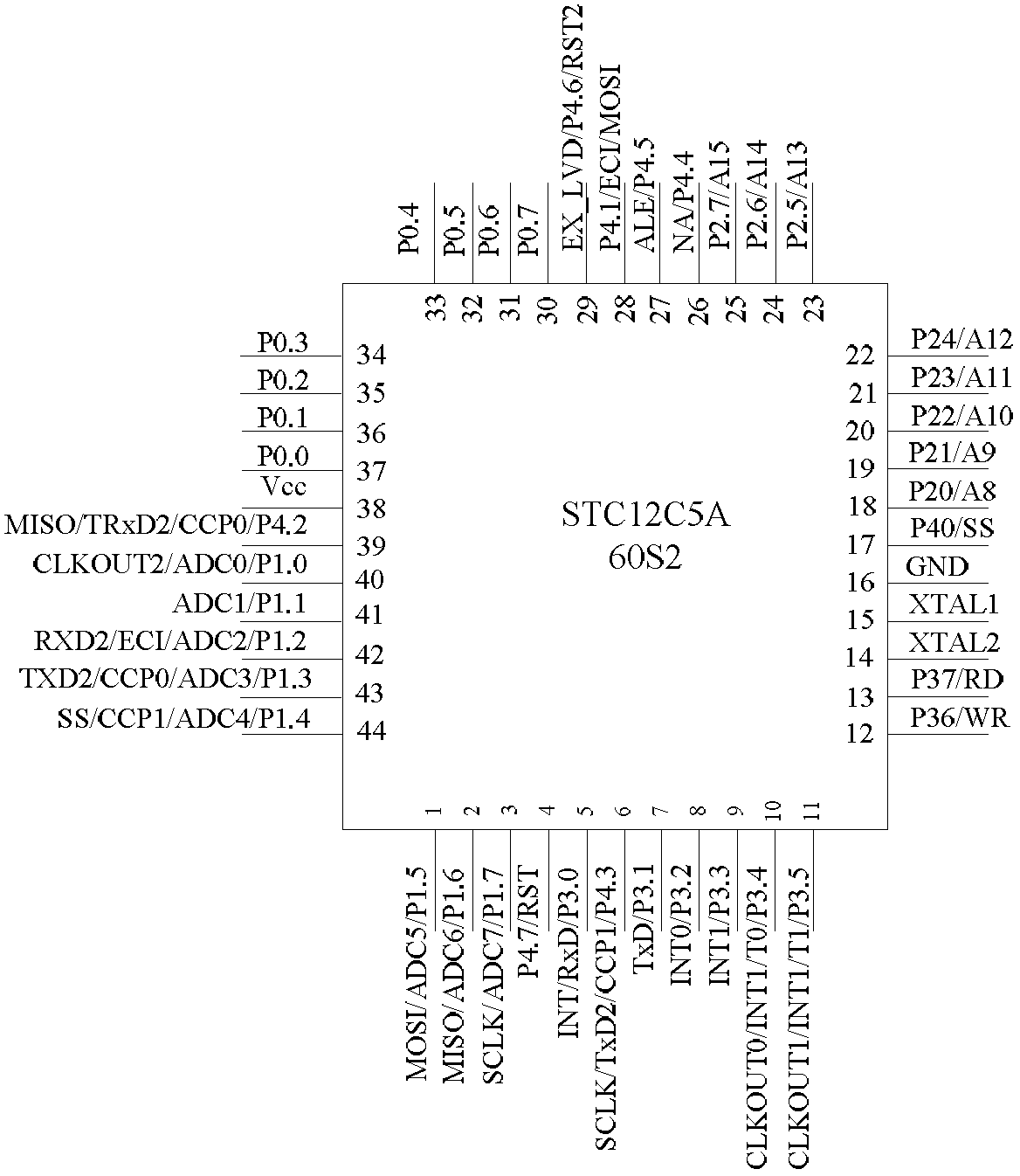

[0034] The present invention will be further described below in conjunction with accompanying drawing:

[0035]Firstly, the detection principle of the present invention is introduced: the detection principle of the present invention is eddy current detection, which is a non-destructive detection method based on the principle of electromagnetic induction, and is suitable for the case where the container base is iron-based. When the alternating current passes through the probe composed of electromagnetic sensors, the high-frequency AC signal generates an electromagnetic field in the probe coil, and when the probe is close to the conductor, an eddy current is formed in it. The closer the probe is to the conductive substrate, the greater the eddy current and the greater the reflection impedance. This feedback action characterizes the size of the distance between the probe head and the conductive substrate, that is, the thickness of the non-conductive coating on the conductive subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com