Cladding light filtering structure and manufacturing method thereof

A cladding light and filtering technology, which is applied in the direction of the structure/shape of the active medium, can solve the problems of high local temperature, limited filtering capacity, and absolute increase, so as to achieve uniform temperature distribution, eliminate excessive heat concentration, and reduce The effect of temperature break point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

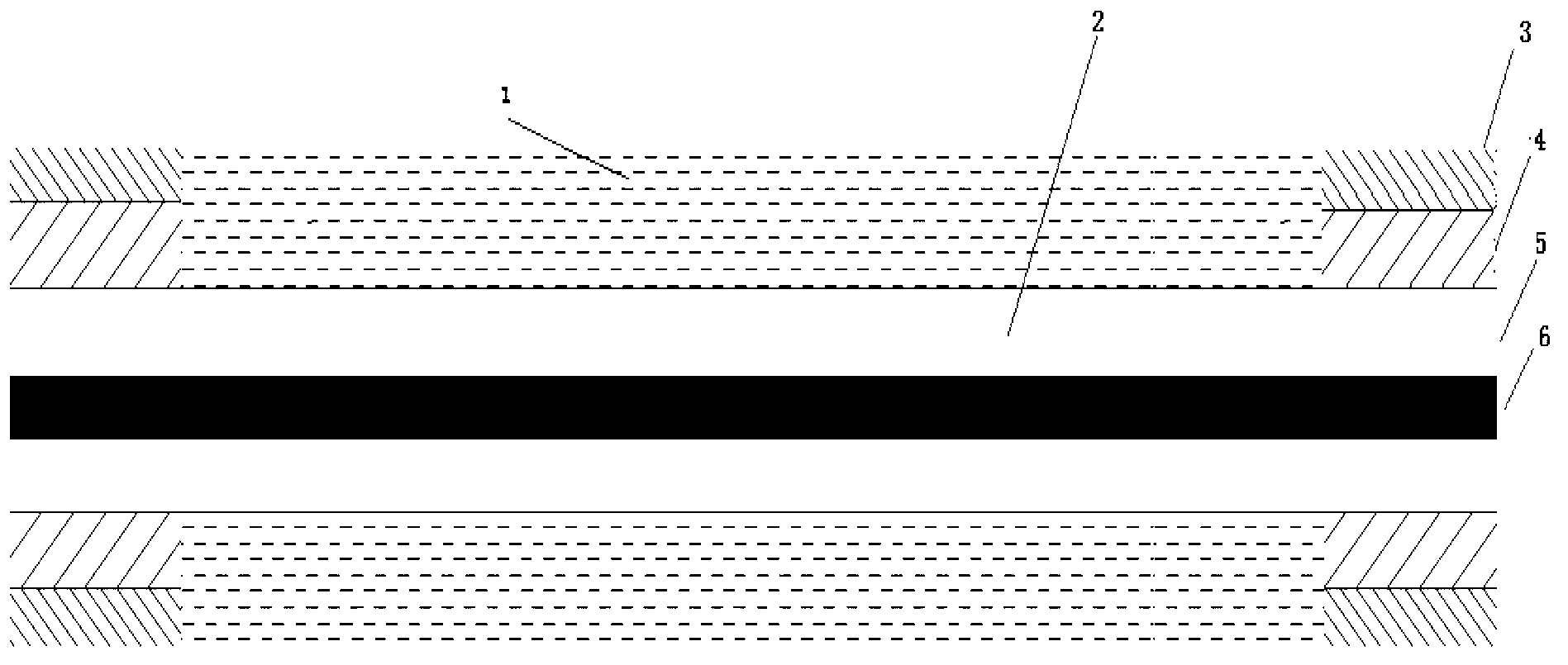

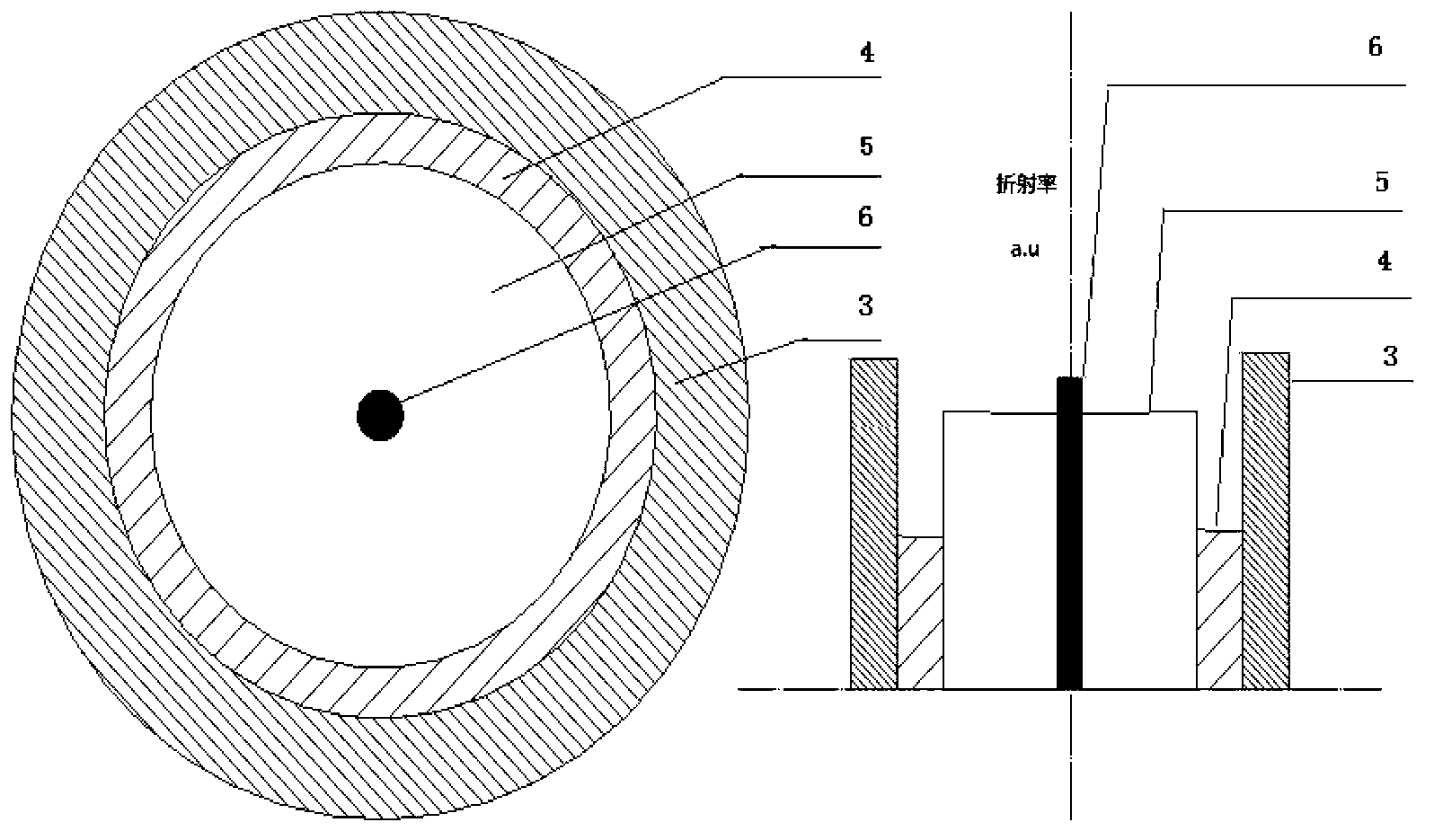

[0045] see first image 3 , image 3 It is a schematic diagram of filtering in which various filter materials are continuously coated in sections in Example 1 of the present invention. It can be seen from the figure that the cladding light filtering structure of this embodiment includes peeling off the protective layer 3, the outer cladding 4, and exposing a section of glass cladding. Layer 5 of the optical fiber 2 and the coating of the filter material 1 on the glass cladding 5, the refractive index of the filter material 1 is higher than the refractive index of the outer cladding 4 of the optical fiber 2, the The filter material 1 coating is coated on the coating segment with five different filter materials in sequence, the interval between each coating segment is equal to zero, and the refraction of the filter material of each coating segment The rate increases gradually from small to achieve relatively uniform filtered light of each coating segment.

[0046] A silica fib...

Embodiment 2

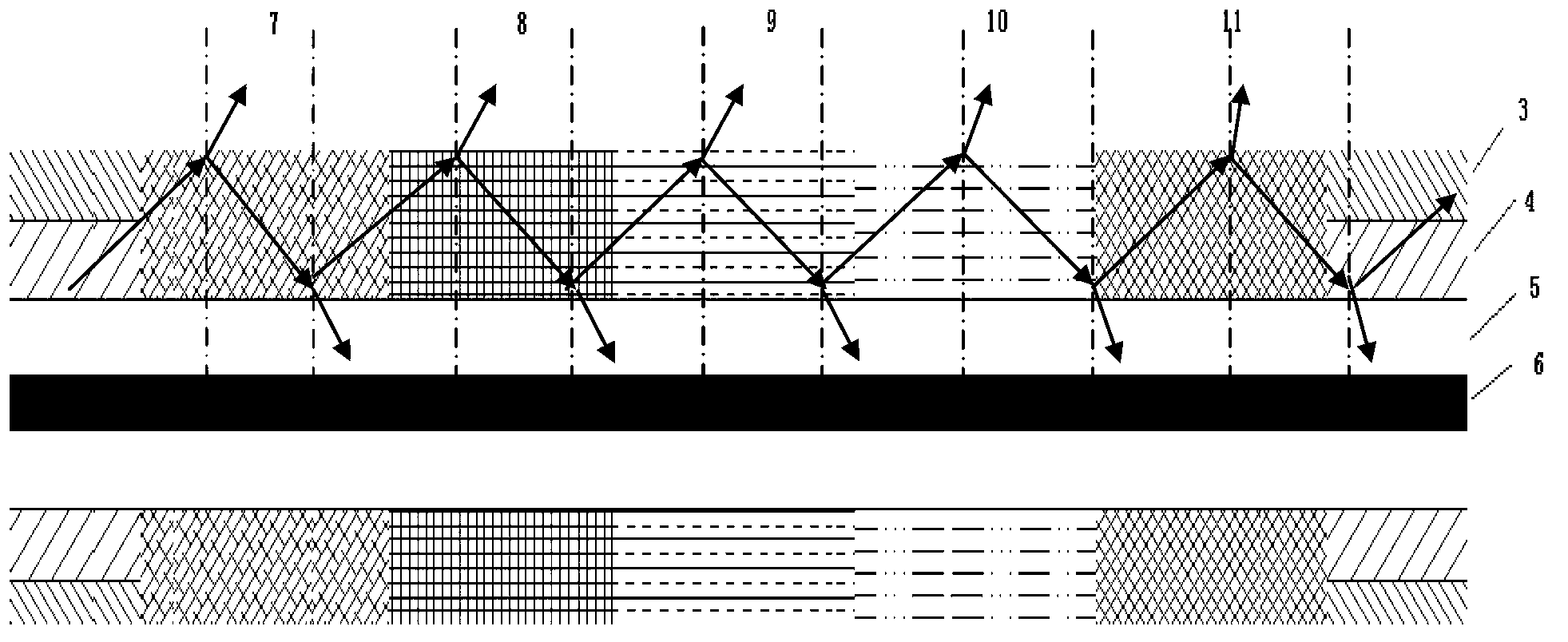

[0048] see first Figure 4 , Figure 4 It is a schematic diagram of the filtering of a single filter material segmented coating in Example 2 of the present invention. It can be seen from the figure that the cladding light filtering structure of this embodiment includes peeling off the protective layer 3 and the outer cladding 4, and exposing a section of the glass cladding The optical fiber 2 of 5 and the optical filter material 1 coating on the glass cladding 5, the refractive index of the optical filter material 1 is higher than the refractive index of the outer cladding 4 of the optical fiber 2, and the The coating of filter material 1 is a coating segment coated with the same filter material, and the interval between each coating segment is greater than zero, and the length of each coating segment gradually increases from short to long. The filtered light reaching each coating segment is relatively uniform.

[0049] In this embodiment, a silica fiber with a core 6 diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com