System and method for retraining high-frequency vibration of low-pressure large-power multi-phase variable frequency motor

A high-frequency vibration, variable frequency motor technology, used in control systems, control generators, vector control systems, etc., can solve the problems of noise pollution, no obvious change in vibration energy, etc., and achieve the effect of reducing high-frequency vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

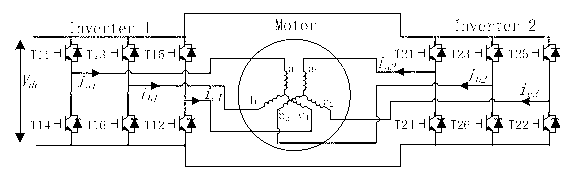

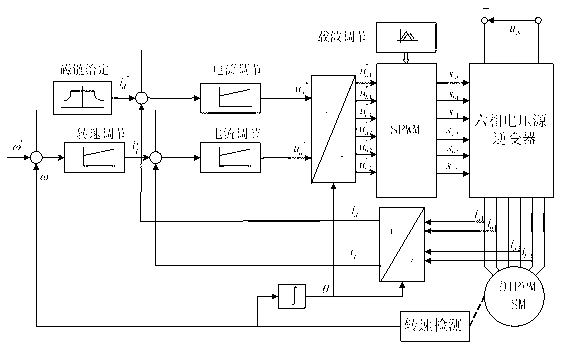

[0014] 1. First, the theoretical basis involved in the present invention is introduced.

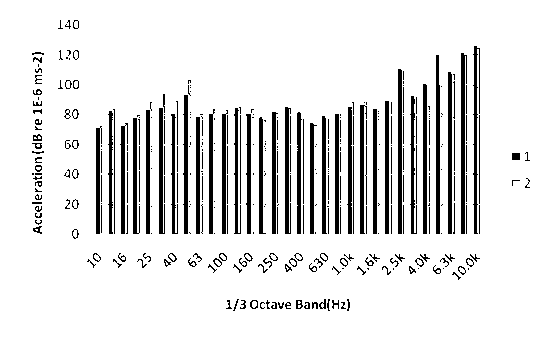

[0015] The high-frequency vibration of the variable frequency motor is mainly excited by electromagnetic force waves, especially the radial Maxwell force in the air gap of the motor, which is generated by the interaction between the stator magnetic field and the rotor magnetic field. Vibration and noise are large.

[0016] The Maxwell force acting on the motor stator can be characterized by the pressure distribution in the air gap, and the pressure distribution in the air gap can be expressed as:

[0017] (1)

[0018] In the above formula, Bg and μ 0 respectively represent the radial magnetic induction intensity and air permeability in the air gap. The radial magnetic induction intensity in the air gap can be expressed as:

[0019] (2)

[0020] represents the permeance, f mm Expressed as magnetomotive force. Therefore, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com