Wool shearing facility

A technology for shearing and facilities, applied in other equipment, cleaning devices, applications, etc., can solve the problems of sheep and shearing personnel casualties, affecting work efficiency, irregularities, etc., and achieve low risk of wool pollution, reduce labor intensity, and improve operation efficiency. The effect of regional norms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

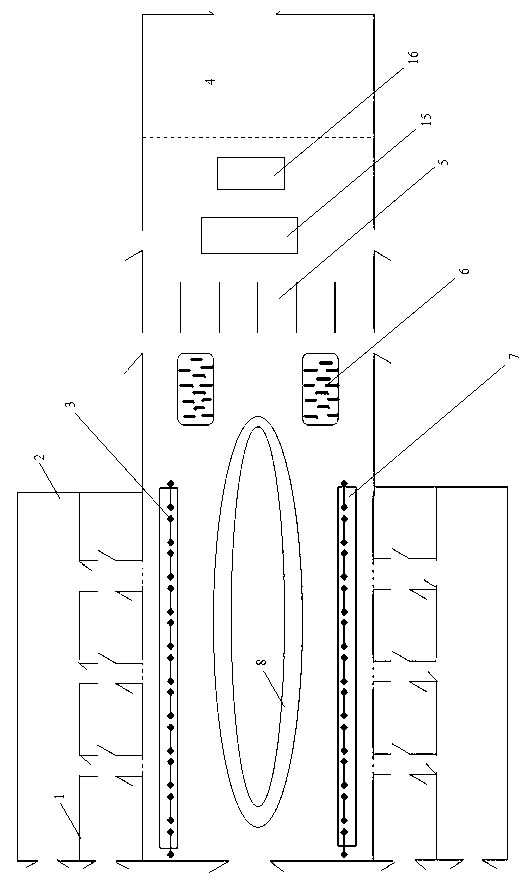

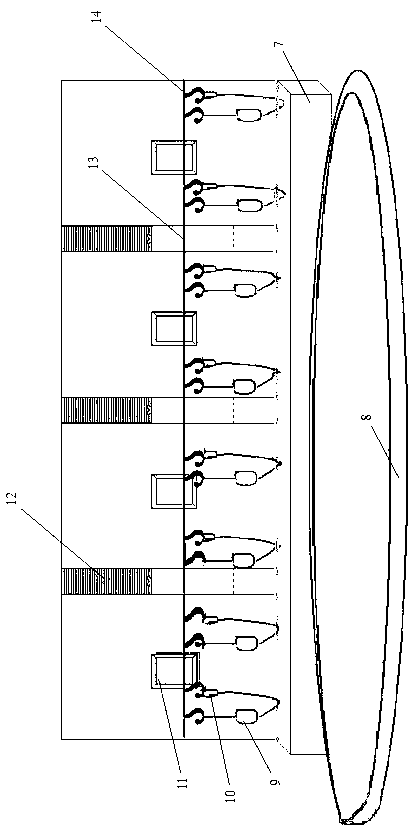

[0022] The present invention is illustrated below in conjunction with the accompanying drawings.

[0023] The facility of the present invention can be arranged in a large brick-wood or color steel structure factory building, preferably the height of the factory building is more than 2.5m, the factory building should be able to prevent rain, be dry, ventilated, have good light, and its inner wall and ground should be smooth and solid , No lint, easy to clean and convenient to disinfect. The area of factory building can be designed according to the scale of sheared sheep, and whole facility of the present invention is set in factory building, and shearing area, wool static area, grading area, temporary storage area, packing and brushing mark area, storage bag are arranged vertically. five main parts including the sheep-shearing area, as well as functional areas such as the rest room before sheep shearing and the rest room after sheep shearing. The structural layout of each fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com