Preparation method of coffee-starch composite particles and application of coffee-starch composite particles in cigarette filter

A technology of composite granules and starch, applied in the application, e-liquid filter, tobacco and other directions, can solve the problems of potential safety hazards of chemical adhesives, low starch granule yield, unstable coffee aroma, etc., to improve the smoking quality of cigarettes , The effect of increasing aroma richness and stabilizing coffee aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

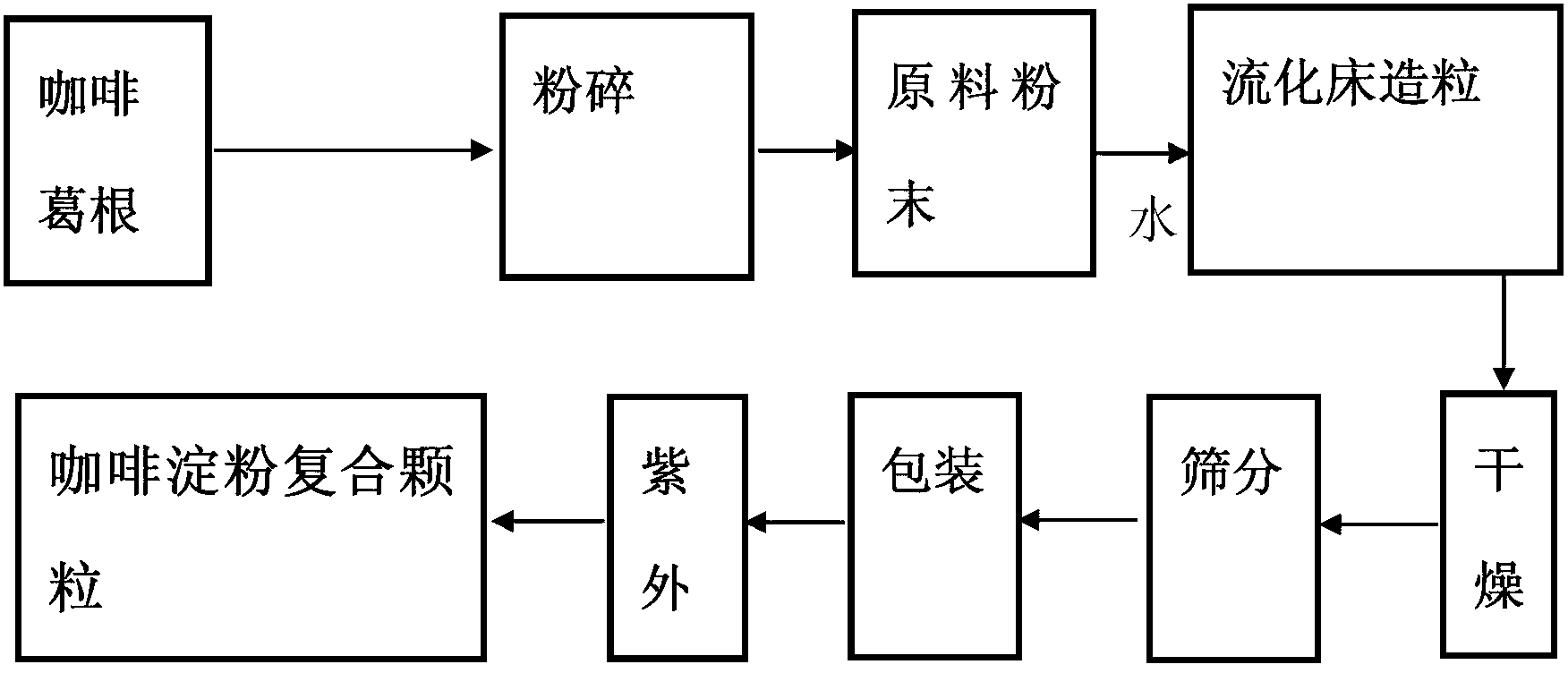

[0037] ⑴Mix the coffee beans and kudzu root to be crushed in a ratio of 2:1 (by weight) and pour them into the feed port of the ZSJB universal grinder, and collect the raw materials of composite particles containing coffee and starch below 80 mesh at the discharge port of the ZSJB universal grinder powder;

[0038]⑵Preparation before granulation. Before each batch of granules is produced, the granulator should be run dry for 1-2 hours; the heating temperature should be set to 120°C, and the fan frequency should be set to 30-40HZ to heat and sterilize the inside of the granulator; Choose FL‐30 boiling granulator;

[0039] (3) Turn on the main power supply and the main air source of the granulator, and put the feed liquid pipe of the peristaltic pump into a container filled with clean water;

[0040] (4) Weigh the composite granule raw material powder containing coffee and starch prepared in step (1), pour it into the fluidized bed of the granulator, adjust the position of the ...

preparation Embodiment 2

[0050] According to Preparation Example 1, in step (1), the coffee beans to be pulverized and kudzu root are mixed in a ratio of 4:1 (weight) and poured into the feed port of the pulverizer. In step (6), the fan frequency is set to 32Hz, and in step (7 ) to adjust the pump speed to 160rpm, and the rest were prepared according to Preparation Example 1 to obtain "coffee starch composite granules 2#".

preparation Embodiment 3

[0052] According to Preparation Example 1, when heating is turned on in step (8), set the heating temperature of the fluidized bed to 130°C, and follow the rest of Preparation Example 1 to obtain "coffee starch composite granules 3#".

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com