Powder feeding dust removal device

A technology of dust removal device and powder, which is applied in the direction of cyclone device, etc., can solve the problems of air pollution, high labor intensity, high device cost, etc., and achieve the effects of reducing labor intensity, scientific and reasonable operation, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

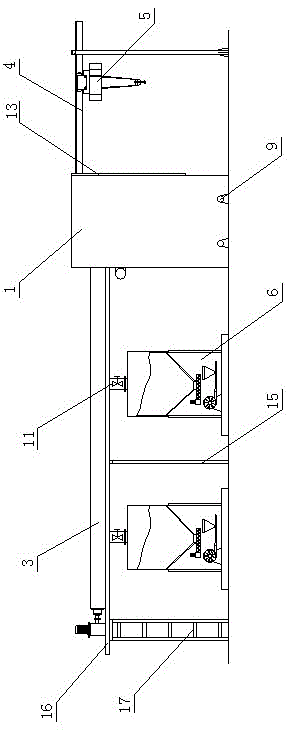

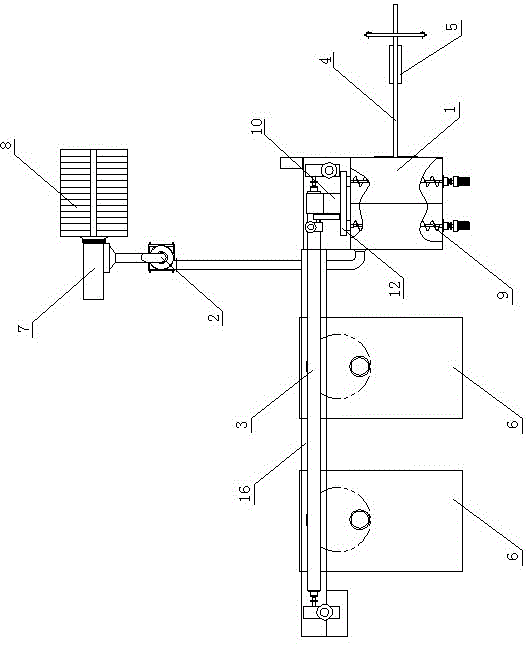

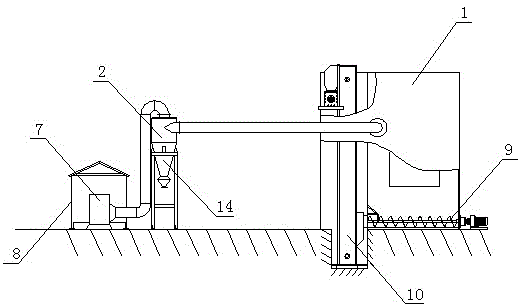

[0017] The powder feeding and dedusting device of the present invention is composed of a powder chamber 1, a cyclone separator 2 and a powder conveying distributor 3. A bin door 13 is provided above one end of the powder chamber 1. The upper part of the powder chamber 1, the bin One end of the door 13 is horizontally provided with a bracket-type guide rail 4 leading to the inside of the powder chamber 1, a traction crane 5 is installed on the bracket-type guide rail 4, and the other end of the powder chamber 1 opposite to the bracket-type guide rail 4 is horizontally provided with a powder chamber. Material conveying distributor 3, more than one group of dispersion tanks 6 are arranged below the powder conveying distributor 3 to communicate with their pipelines; one side pipeline of the powder chamber 1 is connected to the cyclone separator 2, and the outlet of the cyclone separator 2 is connected to the fan 7 is connected, the outlet of the fan 7 is connected to the fine powde...

Embodiment 2

[0019] The powder feeding and dedusting device of the present invention is composed of a powder chamber 1, a cyclone separator 2 and a powder conveying distributor 3. A bin door 13 is provided above one end of the powder chamber 1. The upper part of the powder chamber 1, the bin One end of the door 13 is horizontally provided with a bracket-type guide rail 4 leading to the inside of the powder chamber 1, on which a traction crane 5 is installed, and the other end of the powder chamber 1 opposite to the bracket-type guide rail 4 is horizontally provided with a powder chamber. The material conveying distributor 3 is provided below the powder conveying distributor 3 with more than one group of dispersion tanks 6 communicating with its pipeline, and a control valve 11 is arranged on the connected pipeline. One side of the pipeline of the powder chamber 1 is connected to the cyclone separator 2, and the dust-reducing cylinder 14 of the cyclone separator 2 is a spiral inverted cone. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com