Extrusion rod and application of extrusion rod to sunflower heat dissipater profile

A technology of extruding rods and indenters, which is applied in the direction of metal extrusion, indenters/punch rods, heat exchange equipment, etc., which can solve the problems of difficult production of Sunflower radiators, difficult flow of metal materials, dead zones at the front of the mold, etc. , to achieve the effect of reducing the formation of dead zones, rationally distributing metal materials, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

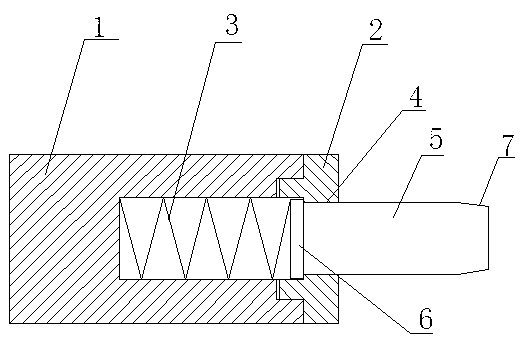

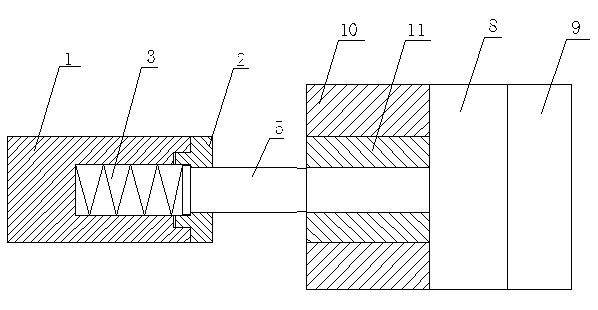

[0016] 1. The structure of extrusion rod:

[0017] Such as figure 1 As shown, the present invention includes a cylindrical main body 1 with an open end at one end, a spring 3 is arranged in the cylindrical main body 1, a pressure head 2 is screwed to the open end of the cylindrical main body 1, and a spring connection with the spring is set on the pressure head 2. 3 coaxial through holes 4, an inner support rod 5 is interspersed in the through hole 4, the front end of the inner support rod 5 is fixedly connected to the rod head 6, and the rod head 6 is arranged in the cylindrical main body 1 in a gap manner, The outer diameter of the rear end of the inner support rod 5 is a tapered transition surface 7 that gradually decreases.

[0018] 2. Processing technology:

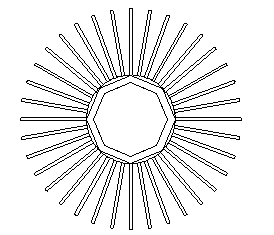

[0019] Taking 6063 aluminum alloy as an example, the sun flower radiator produced by the present invention is as follows: figure 2 shown.

[0020] Before extrusion, the 6063 aluminum alloy tubular billet is homo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com