Press machine body welding deformation eliminating method based on residual stress quantitative analysis

A residual stress and welding deformation technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems affecting the quality of the machine body, shorten the welding cycle, and deform the machine body, so as to improve the welding efficiency and optimize the welding path. , the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

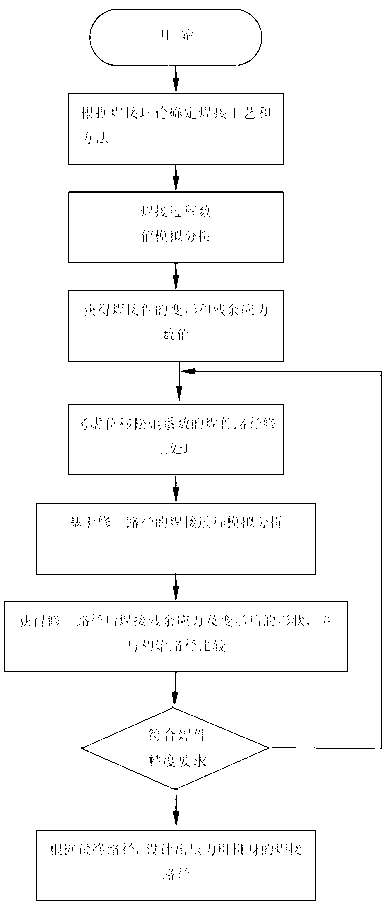

[0023] The flow chart of the present invention is as figure 1 As shown, the method for eliminating the welding deformation of the press fuselage based on the quantitative analysis of residual stress of the present invention includes the following steps:

[0024] 1) Determine the reasonable welding process conditions such as groove form and welding process parameters, and the initial welding path from inside to outside. Welding process parameters include current, voltage, number of welding layers, number of passes, etc.;

[0025] 2) The initial model of the fuselage structure is divided into unit mesh nodes, and the numerical simulation analysis of the welding process is carried out;

[0026] 3) Obtain the residual stress and the deformation caused by each element node position of each weld;

[0027] 4) Correct the original welding path of the fuselage components after multiplying the deformation caused by the node residual stress by a displacement relaxation coefficient less ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com