Method for preventing burning losses of threads of transformer plug base

A technology for screw fasteners and transformers, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting assembly, easy burning of threads, and difficult cleaning of foreign particles. The method is simple and practical, and the electrical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

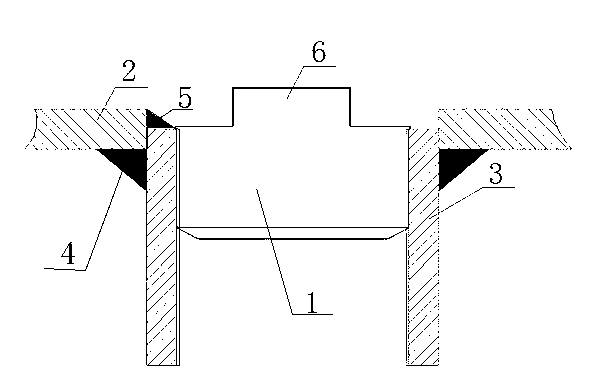

[0016] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0017] A method for preventing a threaded buckle from being burned by a transformer plug seat, comprising the following process steps:

[0018] ①Insert one end of the plug seat 3 into the plug seat mounting hole of the transformer oil tank steel plate 2, the other end of the plug seat is exposed outside the transformer oil tank steel plate, the plug seat and the transformer oil tank steel plate protrude vertically, and then weld the plug seat and the transformer oil tank steel plate The outer weld 4 is welded around the mounting hole of the plug seat;

[0019] ②After the outer weld seam is welded, screw a stud 1 from the transformer oil tank into the plug seat and tighten it. The stud is a wooden stud. Before screwing into the plug seat, the stud should be soaked in water for 1 minute The above; the studs are made of wood mainly because the woo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com