Method for machining inner gear ring

A processing method and technology of an internal gear ring, applied in the field of mechanical processing, can solve problems such as long production process, and achieve the effects of simple processing process, high surface hardness and simple processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

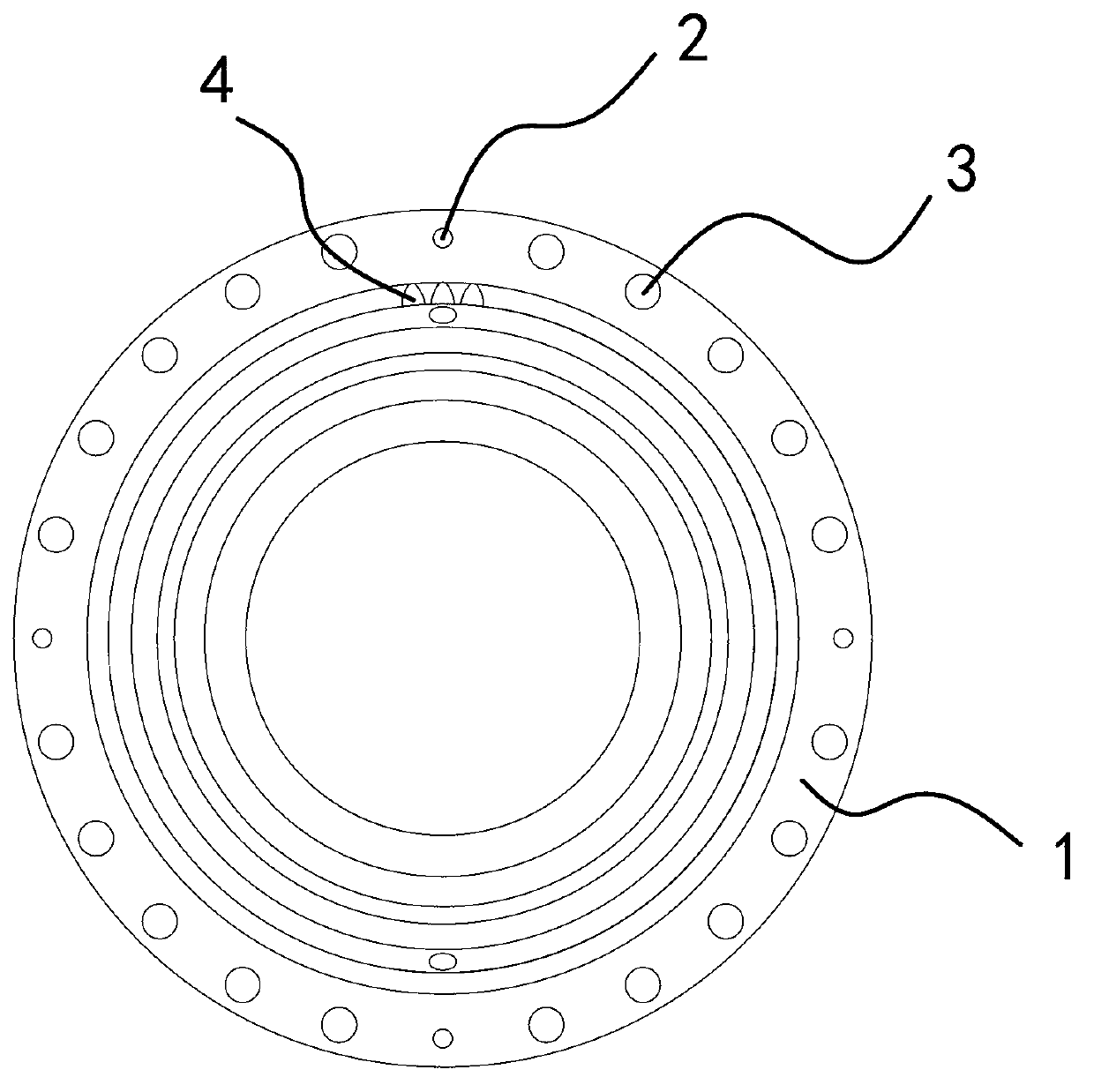

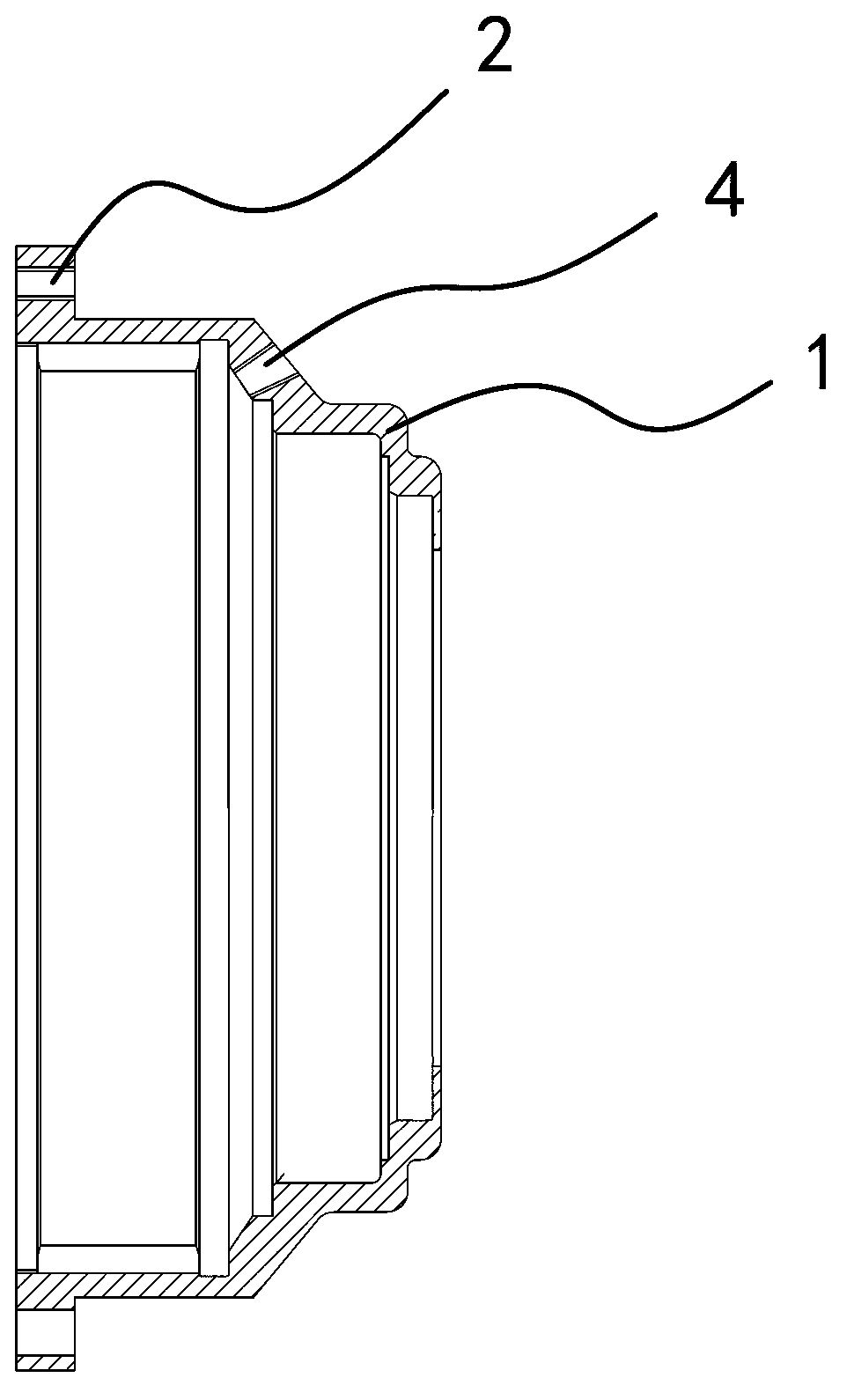

Image

Examples

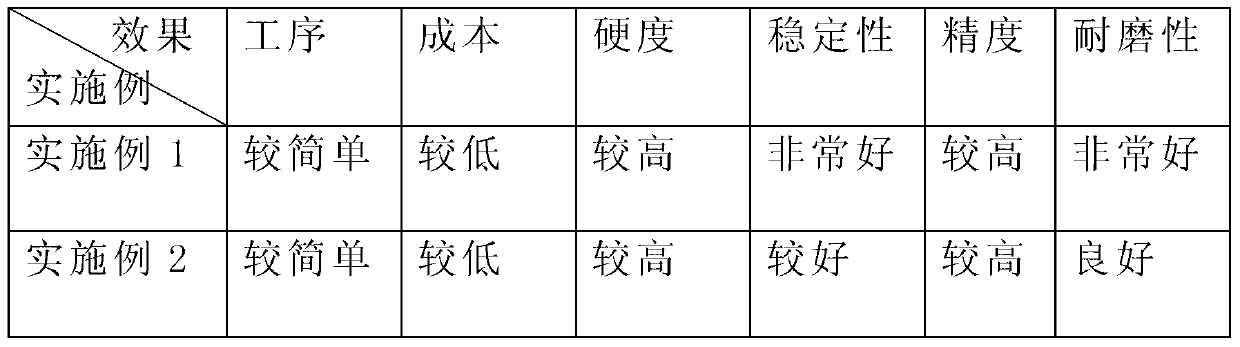

Embodiment 1

[0030] Forging and forming: choose commercially available ordinary steel, reserve margin according to the requirements of the drawings, and forge and form.

[0031] Rough machining: remove a large amount of allowance, and preliminarily shape the holes and end faces.

[0032] Quenching and tempering: After the rough machining of the ring gear is normalized at 900°C, it is tempered at 850°C.

[0033] Finishing: After quenching and tempering, the inner ring gear is finished and then sent to the machining center for drilling and tapping.

[0034] Two-step gear shaping: After the ring gear is rough gear shaped, it is tempered and shaped at 250°C for 3 hours, and after tempering, it is finely gear shaped.

[0035] Nitriding treatment: heat up the inner ring gear after gear shaping to the nitriding treatment temperature of 520°C in a saturated atmosphere filled with nitrogen, keep it warm for 48 hours, and then lower the temperature. The nitriding cycle is 5 days. The surface harde...

Embodiment 2

[0038] Forging and forming: choose commercially available ordinary steel, reserve margin according to the requirements of the drawings, and forge and form.

[0039] Rough machining: remove a large amount of allowance, and preliminarily shape the holes and end faces.

[0040] Quenching and tempering: After the rough machined ring gear is normalized at 920°C, it is tempered at 830°C.

[0041] Finishing: After quenching and tempering, the inner ring gear is finished and then sent to the machining center for drilling and tapping.

[0042] Two-step gear shaping: After the ring gear is rough gear shaped, it is tempered and shaped at 200°C for 3 hours, and after tempering, it is finely gear shaped.

[0043] Nitriding treatment: heat up the inner ring gear after gear shaping to 500°C for nitriding treatment in a saturated atmosphere filled with nitrogen, keep it warm for 45 hours, and then lower the temperature. The nitriding cycle is 5 days. The surface hardening speed of the inner...

Embodiment 3

[0046] Forging and forming: choose commercially available ordinary steel, reserve margin according to the requirements of the drawings, and forge and form.

[0047] Rough machining: remove a large amount of allowance, and preliminarily shape the holes and end faces.

[0048] Quenching and tempering: After the rough machining of the ring gear is normalized at 930°C, it is tempered at 870°C.

[0049] Finishing: After quenching and tempering, the inner ring gear is finished and then sent to the machining center for drilling and tapping.

[0050] Two-step gear shaping: rough gear shaping of the ring gear, tempering and shaping at 300°C for 4 hours, and fine gear shaping after tempering.

[0051] Nitriding treatment: heat up the inner ring gear after gear shaping to the nitriding treatment temperature of 550°C in a saturated atmosphere filled with nitrogen, keep it warm for 50 hours, and then lower the temperature. The nitriding cycle is 5 days. Among them, the surface hardening sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com